Can manufacturing organizations tackle the skills gap by adopting an economic approach that blends adaptive and role-based skills?

By Lisa Caldwell, EY Americas Business Consulting Leader; and Steve Fuller, Partner, People Consulting, Ernst & Young LLP

Manufacturing organizations increasingly say their inability to find enough qualified workers impacts key business decisions, from expanding operations to entering new markets. An estimated 2.1 million manufacturing jobs could go unfilled by 2030 if manufacturers don’t address the skills gap challenging the industry.

To close this gap, many organizations are increasingly targeting adaptive skills as they invest in training initiatives. Workers who hone adaptive skills such as critical thinking, communication and teamwork are more likely to accelerate professional development and find alternative career paths. But just seeking to strengthen adaptive skills may not be enough. A 2024 study conducted by EY Consulting in conjunction with the Manufacturing Institute suggests that driving transformational change also requires manufacturing organizations to focus on achieving the right complement of adaptive and traditional role-based skills.

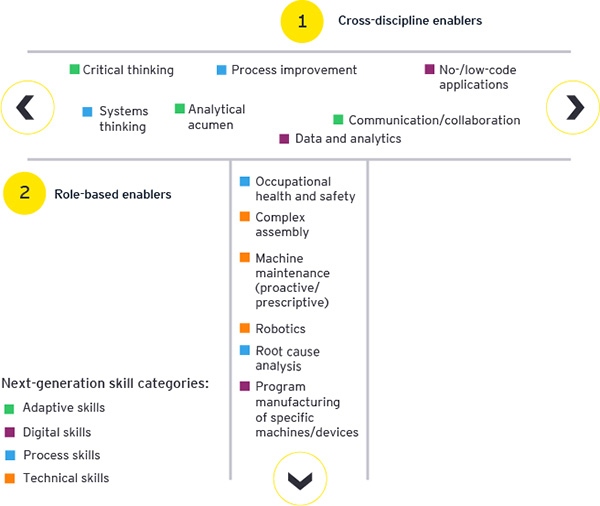

The research led to the development of a new construct for enhancing skills in manufacturing organizations: the “Manufacturing T,” which organizes four broad categories of adaptive, digital, technical and manufacturing capabilities. These next-generation building blocks can help organizations determine where and how to direct their investment in hiring and capability development.

Cross-discipline enablers that comprise the top of the T are transferrable skills and capabilities that can be trained broadly across the organization. These skills also provide a critical foundation that accelerates organizational transformation and are key to breaking down silos and serve as a critical step for inspiring innovative thinking in new and unexpected areas.

The bottom leg of the T is comprised of role-based enablers that address the direct role evolutions experienced by the production workforce, including expectations to hold multiple roles and interface with digital tools. Developing these skills accelerates the production workforce’s ability to evolve alongside the changing shop floor, driving improvements in productivity, employee experience, quality and safety.

Moreover, just as our research revealed there is no one-size-fits-all approach for organizations to address the T, the same is also true for each organization, which has its own considerations and challenges to address. In the study, we defined four archetypes that organizations can use to self-identify to inform their approach to investing in next-generation skills across the T.

The break-through innovators are often agile manufacturing organizations in nascent and emerging industries focused on rapid growth, while also working toward increased standardization. For these companies, available talent pools with applicable skills are often limited due to the relative immaturity of the industry and a lack of existing standardization.

The empowered executors are typically stable manufacturing organizations in well-defined industries that need to emphasize and enhance process efficiencies through the introduction of enabling technologies on the shopfloor. Deploying the new technologies has triggered significant evolution within production roles, from automation and robotics to the overlay of sensors and programmable logic controllers onto legacy manufacturing assets.

The transformation driver includes well-established organizations seeking to expand in evolving industries by focusing on driving digital transformation to scale and become future-fit. Amidst ongoing evolutions on both the industry and production floor fronts, manufacturers must identify where they must prioritize skill investments to accelerate transformation and enable a future-fitted workforce.

The dynamic shapeshifter is typically comprised of dynamic organizations that span multiple industries and focus on building multifaceted capabilities through acquisitions, investments and hiring. Due to the complexities of skills and operating models seen at many large-scale conglomerates, these manufacturers face significant challenges, from bridging organizational silos to facilitating talent mobility.

Manufacturing organizations must evaluate three critical components – skill definition, skill assessment and learning experience value – when evaluating whether reskilling assessments are sound economically. The following three questions focus on identifying the right skills, assessing employee values and aligning learning delivery with engaging mechanisms.

Are we investing in the right skills? The World Economic Forum’s 2023 Future of Jobs Report revealed that less than 50% of organizations prioritize developing next-generation skills within their own organization. This means that many manufacturing organizations are turning to external sources to fill the skills gap. This is not only the most expensive response, but it also often represents a short-term fix. Instead, manufacturers need to adopt a forward-looking approach to reskilling existing employees that will help them achieve sustainable talent longevity.

Are the skills we are investing in desirable to employees to improve attraction, retention and employee experience? When manufacturers invest in the right skills, they create a win-win for the employer and the workforce. The 2023 EY-MI Adaptive Skills Research2 determined that manufacturing jobs that offer individualized learning and a clearer path for career progression are more attractive to recruits and have greater learning retention.

Are manufacturers investing in skills with the right intensity? Many manufacturing organizations struggle to deliver enough development opportunities and instead rely on a “one-size-fits-all” approach. On the other hand, organizations that offer targeted development experiences often succeed in creating strong incentives for employees to acquire desired skill sets. These pay-for-skills opportunities can significantly improve retention, especially among earlier career employees.

Helping new employees contribute to their long-term success represents one of the more significant payoffs for training investments. Many members of the GenZ cohort are opting to pursue skilled trades over traditional two- and four-year college degrees. Applying new concepts like the “Manufacturing T” will help organizations bring this next generation of workers up to speed. Moreover, it will also position companies to keep pace in a rapidly changing competitive landscape.

The views reflected in this article are the views of the authors and do not necessarily reflect the views of Ernst & Young LLP or other members of the global EY organization.

Lisa Caldwell, EY Americas Business Consulting Leader

Lisa is a business strategist and transformation advisor to public and private C-suite executives. She has over 35 years of experience driving long-term value for clients and profitable growth as a business leader. Her experience includes driving large-scale enterprise transformations in strategic planning, business model transformation, supply chain optimization, digital manufacturing, technology-driven change, analytics, operational efficiency and cognitive systems implementation.

As the EY Americas Business Consulting Leader, Lisa directs the strategy, service delivery, operations, workforce development, and deployment and delivery of value to EY clients. She leads business-led, tech-enabled growth of capabilities and solutions in Business Transformation, Finance, Supply Chain, Enterprise Risk and Technology Risk.

Steve Fuller, Partner, US People Advisory Services

Steve is a transformational leader with deep experience across a range of HR and talent topics. His industry experience is notable, having served clients across the aerospace and defense industry. Steve brings rich experiences navigating HR functions through significant transactions, transformations and major compliance events. Steve’s teams have helped clients with strategic people development initiatives, including competency design, leadership development, change management, culture transformation and more. Finally, he brings experience across the full employee life cycle, including talent acquisition, performance management, careers and learning.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.