Boosting efficiency and performance to your AI server.

AI servers now outgrow air cooling. Data centers are shifting to liquid, raising the quality bar for liquid-cooling parts. This article shows how CNC precision machining turns designs—water blocks, water clod plates, and fine heat-dissipation features—into reliable, scalable hardware.

Air can no longer keep junction temperatures in check as AI server power density climbs. The points below explain why liquid is taking over and how quality in liquid cooling parts directly shapes stable performance.

Liquid removes heat faster than air, enabling steady clocks, lower noise, and better PUE. It supports denser racks and warmer inlets, which cut cooling energy. For sustained AI workloads, liquid cooling stabilizes thermals and uptime.

Performance hinges on precision. Flatness reduces contact resistance. Surface roughness and burr-free edges protect seals and prevent fouling. Consistent microchannels lower pressure drop and balance flow across the AI server.

With the thermal case made, the focus shifts to the parts that turn coolant into real heat removal. Below we introduce each component and the CNC methods used to machine them.

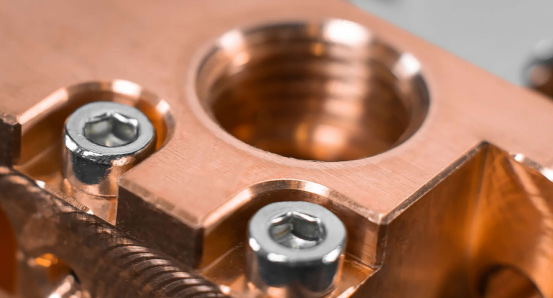

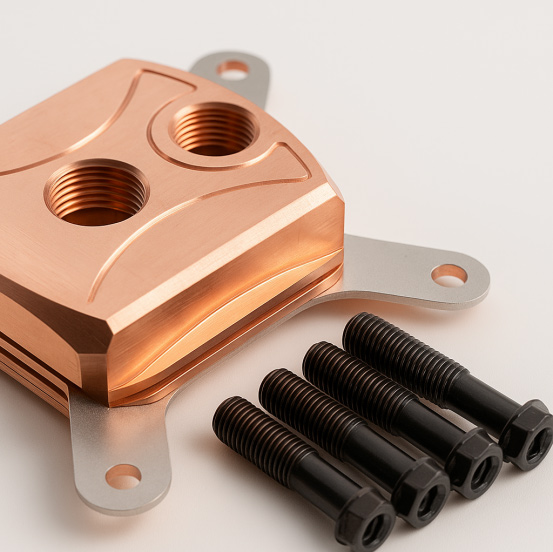

The machined water block is the loop’s heart; channel precision and die-side flatness decide delta-T, which requires high precision and accuracy machining methods.

Geometry: aligned inlet/outlet ports, thread concentricity, bracket bosses, O-ring lands, and a flat sealing rim within tight position.

Process: 3-/5-axis milling for bosses/ports, thread milling or tapping; mill-turn holds coaxiality; probing and reamed dowels lock registration.

Geometry: plate flatness/parallelism, controlled gasket squeeze, continuous groove.

Process: face-mill datum, light grind/lap; stress-relieve and clamp symmetrically to avoid bow.

It is the main contact surface between the cooled components. Thermal conductivity and heat transfer are the important factors, so to machine a uniform thickness and a primary datum is the key.

Machining these internal pathways should focus on absorbing heat and transporting heat. It requires fine slotting and blend radii, which allows uniform width/depth, and minimum radii.

For these entry and exit ports of cool liquid, keeping precision machining and accuracy is vital. Fine thread milling and face-grooving are the keys.

Regarding heat dissipation in the liquid cooling system, heatsink base and fins are the main parts to work.

Heatsink is also serve as a contact surface and requires a uniform thickness to better transfer heat.

In the liquid cooling system, liquid transferred from the source, through the base, and into the fins. In this part, fine slotting and micro deburring is important.

Picking the right alloy locks in both heat transfer and long-term reliability. Use the notes below to match conductivity, corrosion behavior, and cost with your design intent for AI server duty cycles.

Target high thermal conductivity, good machinability, corrosion resistance in the chosen coolant, and stable properties under clamping loads. Balance weight, recyclability, and cost at data-center scale.

Copper maximizes heat transfer; aluminum reduces weight and cost. Popular choices include C110/C101 copper for conductivity and 6061-T6 aluminum for balanced strength and machinability. Manage galvanic risk in mixed systems with compatible alloys and coatings.

Copper cold plates excel at base-to-coolant heat flux. C110 ETP or oxygen-free copper (C101) pairs well with nickel plating for cleanliness and corrosion control. Tight channels and polished sealing lands protect O-rings over long service intervals.

TUOFA CNC Machining provides one-stop custom solutions—from material selection and compatibility advice to precision machining, finishing, cleaning, and qualification reports.

A solid design still fails without a buildable, repeatable plan. The steps below stabilize channels, seals, and supply so prototypes convert smoothly into volume.

Choose manufacturable channel widths and corner radii that match tool diameters. Keep stable wall thicknesses. Standardize O-ring sizes, groove depths, and port threads. Design for deburr access and define filtration to match channel size.

CMM and optical inspection validate geometry. Surface metrology tracks roughness on sealing faces. Pressure or helium tests confirm leak-tightness. Lots carry serials, material certs, and process records for audits.

Rapid prototypes de-risk flow and assembly. Modular fixtures, multi-axis cells, and in-process probing scale output. Buffer stock and scheduled releases align with AI server rollouts.

As AI server heat rises, cooling is shifting from air to liquid. TUOFA CNC precision machining builds reliable liquid cooling parts—water blocks, water clod plates, fins.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.