July 15, 2019

For all of the miraculous technologies with which 21st-century cultures are confronted–e.g. smartphones, artificial intelligence, and global positioning systems, to name a few–there is one that flies just under the radar. Computer Numerical Control, or CNC, machining is responsible for major advances in the manufacturing process. Essentially CNC machining involves machine tools performing tasks according to the directions of software programs. So, an activated CNC system can direct, for example, a gear shaper to cut a gear’s teeth at a certain pre-set angle or specific speed. In so doing, it increases uniformity and precision with each and every task.

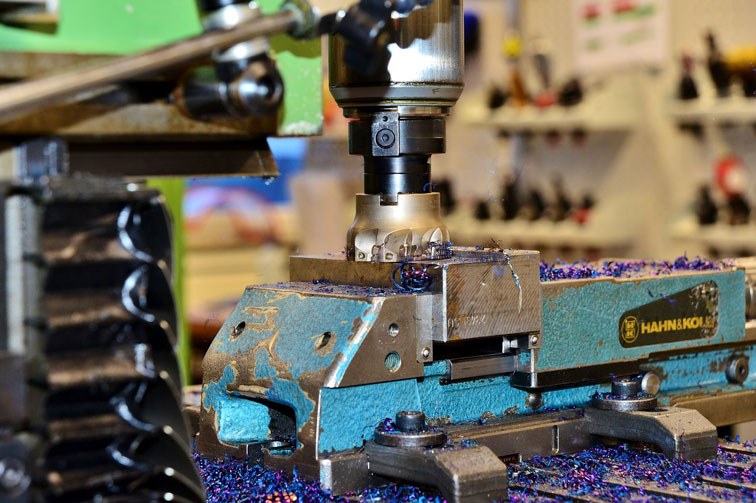

CNC machines are present in various industries. Milling, for example, is the evacuation of surface materials ranging from highways to blades. The cutting tool itself passes over the surface inflicting multiple small cuts with its spinning teeth. Shaved pieces clump together as chips, making them easier to clear. Depending on the materials encountered, and the scope of the project, the milling tool is set at a particular speed or feed rate. Milling machines cut at varied angles along up to five axes. CNC milling is performed with preset feed rate, angle dimensions, and axes. The job gets done with no, or at most minimal, minimal human intervention.

CNC machining services also improve lathe work. A lathe is used to shape metal (or wood) for a distinct purpose. As the workpiece is secured and continuously rotated on a spindle, the lathe made cuts of defined size, angle, and tapering, whether for shaping large metal cylinders or creating the threads for small screws. Lathes work best for pieces where the symmetry converges at a single axis. The cutting tool then moves from the center to the edge. The geometry of camshafts, gun barrels, and furniture legs make lathe turning optimal for these pieces. With CNC machining, the lathe cutting function operates per G-Code instructions that direct the machine on the location, depth, and area for chipping.

3D Hubs is a network of CNC manufacturers. These are independently-owned partner entities, each highly skilled and experienced in the fields of 3D printing and the production of custom parts with CNC machines. 3D Hubs is also specialized in custom injection molding. The array of metals, plastics and surface finishes we employ combines with state-of-the-art workmanship to provide our customers with the versatile inventory of parts and tools. Our online shopping and ordering process keeps lead times modest and prices reasonable. Those in need of a reliable supplier of custom parts should consider 3D HUBS.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.