Pandemic has disrupted manufacturing on a global scale. Learn how Networks address the chaos and smooth transitions back to the new normal.

By: Arun Natarajan, Director of product marketing at Aryaka

The COVID-19 pandemic has been raging since March this year. It has caused disruptions in several sectors, but none more so than the manufacturing industry. Supply chain disruptions, closure of factories—sometimes half a world away, and chaos in the sales channels are just some of the problems very few in this sector were prepared for. Digital advancements over the past five to ten years have helped to soften the blow the pandemic has dealt, but by and large, much of the global manufacturing sector was knocked out in a pretty serious way in 2020. Senior executives have had to rapidly seek answers to questions like – Can I make my supply chain agile quickly? Can I do online RFPs and supplier management? Can I run my factories remotely? Can I ensure social distancing on the factory floor by reducing the number of people on the factory floor? And if so, how?

Fortunately, all these challenges are solvable by the adoption of digital. According to some analysts, because of the changes necessitated by the pandemic, the manufacturing sector will experience the equivalent of five years of innovation in the next 18 months.

A manufacturing execution system (MES) is the “digital brain” at the core of the factory. It helps operations schedule, manage, and track each step during production. As smart factories become a reality, more equipment and machines are connected to the MES to enable real-time monitoring. This ability to operate remotely is a boon during COVID.

Smart Factories during COVID

Smart factories, which integrate several sensors and Industrial IoT devices to automate tasks, are an integral part of the digital transformation story. These sensors also feed tremendous amounts of information back to the MES and big data applications. Analysis of this data allows managers to make real-time adjustments to the manufacturing process. In these COVID times, it also enables remote monitoring and helps reduce the number of people on the shop floor.

SDWAN for Manufacturing

Central to digital transformation in the manufacturing sector are technologies like the Industrial Internet of Things (IIoT), the cloud, and big-data analytics. The introduction of IoT in the manufacturing ecosystem has streamlined the production process by providing real-time feedback and alerts from the factory floor. Vast amounts of data thus collected have paved the way for the meaningful application of machine learning and artificial intelligence algorithms for fault prediction, quality assurance, etc. Cloud adoption in this sector is also on the rise, mainly due to the increased availability of cloud-based manufacturing systems alongside office productivity suites like Office365 and CRM systems like Salesforce. Together, IIoT, cloud, and big data are the technologies driving digital transformation in manufacturing.

In order for these technologies to be successful, the quality of connectivity is critical. The Enterprise WAN should have a robust architecture that is capable of transporting vast amounts of data generated from IIoT devices on the factory floor, prioritize mission-critical data from cloud-based manufacturing systems, support office productivity and CRM SaaS applications while ensuring that machines running AI and ML algorithms have access to data lakes.

Survey Findings

In a series of annual surveys of manufacturing executives to gauge their motivation for migrating to SD-WAN, the findings have held fairly consistent.

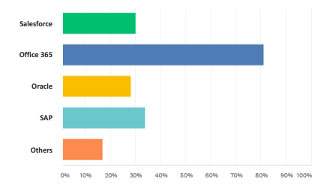

Office365 dominates as the cloud application of choice.

A vast majority of them said enabling remote workers was a key consideration. The most widely used application was Office365, followed by Salesforce, Oracle, and SAP. Some respondents also mentioned engineering apps. These findings are not surprising, given that manufacturing firms have been adopting cloud applications for productivity and factory operations. While it could not have been predicted at the time, enabling remote workers has been key in smart factories remaining operational during COVID-19 pandemic conditions.

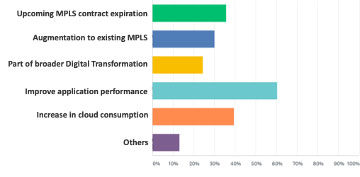

As bandwidth requirements increase, application performance is key.

Delivering cost and operational efficiency was another key motivation for exploring SD-WAN solutions. Some respondents also mentioned the operations in a ‘Lights-Out’ environment. Again, these findings are consistent with our observation and the trend of moving to smart factories.

Some respondents also mentioned MPLS augmentation or MPLS renewal as a triggering point to consider SD-WAN solutions. These findings are also consistent with our understanding that as this sector adopts cloud and SaaS applications, the bandwidth requirements will increase, and augmenting MPLS links to meet this demand will be expensive.

While many organizations have further to go in their digital transformation journey, the move to SD-WAN infrastructure is vital to future-proof any growing company’s cloud and networking needs.

Arun Natarajan

Arun Natarajan is a seasoned marketing professional with nearly two decades in tech. He holds an MBA in Marketing from the London Business School, and has served in executive customer-focused roles in the USA, EU, and APAC regions. He can be contacted at: arun.natarajan@aryaka.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.