Industry 4.0 is here, so manufacturers need to transform their supply chain. In a 2018 Forrester survey, 58% of global decision makers at manufacturing firms said that they are undergoing digital transformation and 19% claim to have already completed that transformation.

The manufacturing industry is no stranger to the concept of continual change. It has often been at the forefront of new technologies and striving to do things more efficiently, such as leading the Six Sigma approach to business.

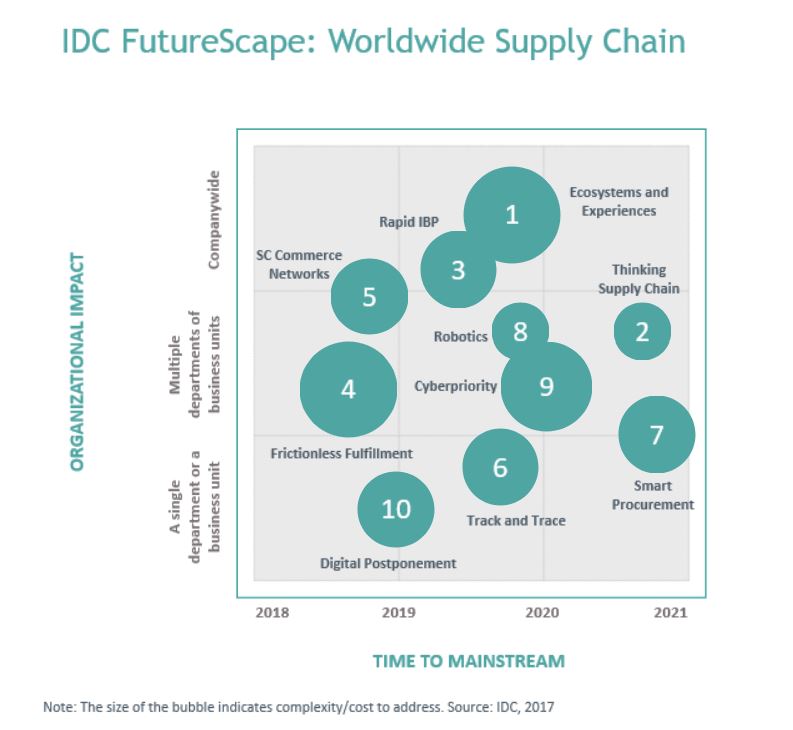

As trends and technology like Blockchain, IoT, AI and robots and robotic management software become the norm, manufacturers need to evolve their processes to keep up-to-date with new technology – and continually adapt to tomorrow’s trends. IDC predicts that the next few years will bring a myriad of new technologies for manufacturers to incorporate into their supply chain. But this isn’t easy when ERP systems were put in years ago and don’t have the adaptability to incorporate new technologies.

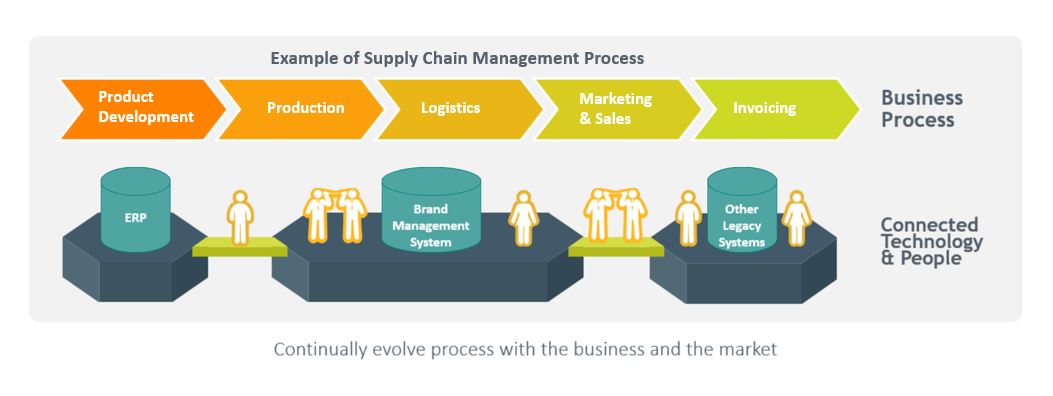

Most supply chain operations will already have an ERP system in place, possibly installed up to 30 years ago. But as new systems and apps have developed, gaps appear between new and legacy systems which means the process is disconnected or inefficient. These gaps are often filled with manual processes which take time to test, roll out and complete.

Tom Pope, Vice President, Manufacturing at Bizagi, the leading enterprise software company for digital transformation, explains why it’s more important now than ever to enable agile supply chain management to keep up with the latest technology releases, and consequently keep up with your competitors.

“Manufacturers need to develop an adaptive toolset for continual change, but rather than taking a rip and replace approach to your ERP – you can converge the old and new systems and automate many of the human processes. An automated supply chain process can help to decrease the order-to-cash time,” says Pope.

This is something that has been recognized across the industry. According to Forrester, “Convergence is a key theme in the Warehouse Manufacturing Systems market. As the supply chain software market consolidates and vendor product portfolios grow, the primary players in the market own an array of supply chain management (SCM) software… The convergence and integration between the systems has the potential to dramatically accelerate SCM efficiency. “

But even when the mainframe and miniframe systems are connected, there can still be inefficiencies. More manufacturers are looking to Digital Process Automation to drive their development. “By automating processes that involve spreadsheets and manual administrative tasks, you can increase operational efficiency and bridge the gaps between ERP and legacy systems, new IoT data, people and robots to perform tasks quicker and more effectively,” advises Pope.

You can then look to incorporate robotics to optimize the process even further. According to IDC, by 2019, robots will be in use in 50% of fulfillment centers, resulting in productivity gains of up to 30% and helping drive down the cost of operations and offset an increasing shortage of labor.

As new technology, such as robotic management and IoT is embraced and usage increases, so does the amount of data and new software. All this information is worthless unless it can be collected and interpreted. All the trends associated with Industry 4.0 incorporate data which need to be analyzed and made sense of as well as being linked to systems and processes.

According to IDC, by the end of 2020, one-third of all manufacturing supply chains will be using analytics-driven cognitive capabilities, thus increasing cost efficiency by 10% and service performance by 5%. For instance, GPS sensors can now be used to track products ‘from floor to store. Forrester cites an example where manufacturers, “use these sensors to gain granular data like the temperature at which an item was stored, how long it spent in cargo and even how long it took to fly off the shelf.” With all the sensors comes more data and this data needs to be linked to other data and to existing systems.

“As one process begins, it often can rely on data collected from another process and system – from data about sensors in new apps and systems to valuable information stored in the legacy systems,” says Pope. “Linking these processes and continually pulling and analyzing information helps to optimize the process, better connects the supply chain and improves the order-to-cash journey across multiple suppliers.”

Getting goods from order-to-cash involves many employees, multiple suppliers and a lot of products. You will need to connect different people (possibly in different countries) with external suppliers to help move things faster through supply chain procedures such as PO changes, labeling, vendor onboarding, buying components from multiple suppliers.

“Each process can take a long time, with many manual (often untraceable) steps involving people that are working in silos, highlights Pope. “Yet you need to improve relationships and processes with factories and suppliers, organize SLAs and remove internal silos if you want to increase productivity. This is another area where digital process automation can help.”

Pope points towards Bizagi customer Adidas, who were able to reimagine their supply chain operations by enabling greater communications between their markets and factories.

“The sports apparel company was looking to increase their operational efficiency by automating ad hoc and manual processes. They hoped that this automation would shorten their time to market while improving their business agility and customer service and improve relationships with factories and suppliers.

“They integrated Bizagi with their ERP and SAP to launch 23 workflow projects in 2 years, with 7 live projected automating 25 processes, used actively by 3,000 internal employees. This resulted in reducing the trade vendor onboarding time by 50%, reducing operating costs by 60% and shortening the traditional supply chain development and delivery time by 75%.”

In the age of Industry 4.0, digital transformation is crucial. But it can be daunting when trying to converge legacy technology with new apps and software. Don’t let this hold you back.

“Bizagi can help to ensure your entire supply chain is connected and as efficient as possible with the help of digital process automation by adding a layer of agility to existing systems. This software will enable your people to collaboratively digitize and automate processes, rapidly optimizing complex operations in order to revolutionize your supply chain,” says Pope.

“We want to help businesses build a flexible and sustainable environment to facilitate structured communication between markets and factories. A truly integrated and efficient supply chain is entirely possible with the right software and the right approach. Give your supply chain an intelligent edge by eliminating your silos and enhancing the business with automation.”

Tom Pope

Tom Pope is Vice President, Manufacturing at Bizagi, and has spent over 20 years implementing transformative software with manufacturers and retailers. During the past four years with Bizagi, the leading enterprise software company for digital transformation, he has helped to transform the manufacturing, supply chain and omni-channel retail experiences for businesses.

Contact:

Click here to contact Bizagi to learn more or to schedule a free product demo.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.