Enterprise asset management (EAM) is more than a glorified maintenance management system. It’s come into its own as a tool for managing the risk profile of capital assets, boosting employee health and safety and protecting the environment. Here, Patrick Zirnhelt, Vice President of Energy & Asset Management, North America, at IFS discusses four areas where EAM can benefit businesses and help them stay safe, compliant, eco-friendly and successful.

EAM software should not only address day-to-day operations and asset maintenance, it should optimize the entire lifecycle – minimizing costs and environmental impact, while maximizing return on capital and productivity.

Constructing new assets consumes many resources from construction materials to placing previously greenfield property under nonpermeable surfaces, making it seldom as conservative as extending an existing assets lifecycle. Additionally, the existing asset must be decommissioned or scuttled, increasing the financial and environmental impact. The capital required for new assets places a burden on a company, its stakeholders and customers.

EAM must address the entire asset lifecycle, from design to decommission. The expense and work of contractors must be included, ensuring costs and specification alterations are captured. This multi-phase view of assets enables a nuanced approach to decisions about lifecycle extension versus replacement. This is why standards such as the ISO-55000 require all asset data to be contained in a single database over its entire lifecycle, and why many investors and utility ratepayer groups want widespread adoption of this standard.

While government regulation is experiencing volatility in the Americas, major corporations continue to place environmental mandates on their trading partners through green supply chain requirements. Many institutions and companies like Walmart and IBM, along with federal governments, have started asking suppliers to reduce their environmental footprints as a way to burnish their own green credentials.

Meeting the green demands of customers and regulators is daunting. Enterprise software products used in manufacturing capture the environmental footprint of a product by recording impact of component parts off the bill of materials and combining it into the impact of a finished assembly. This may be particularly useful in compliance initiatives where chemical composition of a product may be subject to regulation.

EAM ought to document best use practices like the use of gaskets that limit fugitive emissions of greenhouse gasses. In some situations, well-integrated functionality can record an inspection location using GIS technology, the reports or results in embedded document management or prove that qualified personnel are performing maintenance work through embedded human resources functionality. This will go a long way to establishing green credentials.

While sustainability is a growing concern, compliance is absolute. In industries such as food and beverage, the penalty for non-compliance is severe – one slip could seriously harm consumers and businesses.

The food and beverage industry has a vast number of training courses impacting jobs employees can perform. Not only is skill-based workforce scheduling critical to putting the correctly trained employee on the right job to remain compliant, it also ensures that basic floor requirements are met.

This means critical maintenance can be completed between batches without causing delays, and audits can quickly document qualified individuals carried out certain tasks.

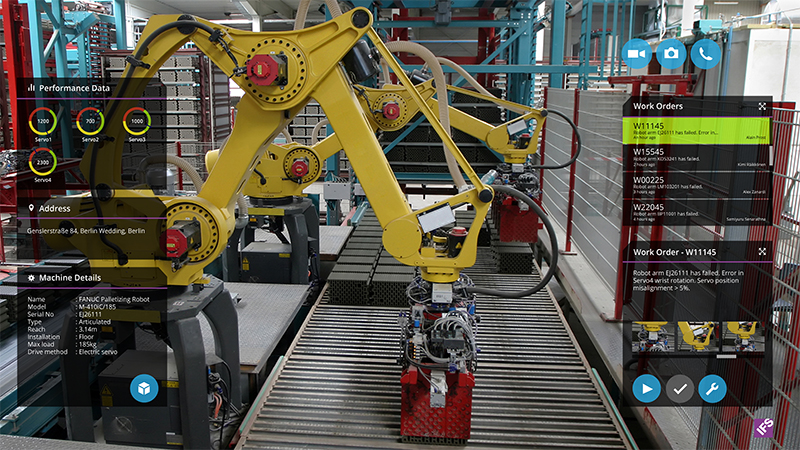

Many asset-intensive organizations house service assets remotely. These may be company owned or belong to the customer, and serviced under an aftermarket agreement. Regardless, the customer experience hinges on efficient, timely service.

In the utilities industry, operations, maintenance and service contractors are often responsible for uptime of distributed assets such as meters or sewers. The failure and resulting downtime of any of these assets carries financial penalties and damages stakeholder perceptions. Ensuring a correctly skilled technician is on site quickly with the right parts to execute the repair is critical.

One Texas-based oilfield company involved with the preparation, assembly and operation of drilling installations, found that software optimized its field maintenance and environmental impact.

The company primarily performs planned, preventive maintenance activities. Delivery and workforce schedules are organized in advance to streamline operations. Since using real-time scheduling optimization software, the company has saved nearly $3 million in fuel costs and reduced its carbon footprint.

The impact of EAM spreads further than simply boosting the bottom line. EAM shouldn’t exist in a ‘bubble’ and apply only to operational assets. With asset capabilities constantly changing and new technologies enhancing the power of data processing, enterprises need access to an EAM system with a 360-degree view of all assets – from design, right through to installation and operations.

The chain reaction will spread further than the assets themselves. In all industries, these benefits can be passed on to employees, customers and the environment by making operations safer, smarter and eco-friendly.

Patrick Zirnhelt is responsible for IFS’s presence in enterprise asset management (EAM) software in North America. He has more than 22 years of experience working with enterprise systems, which includes software development, implementation and sales. He is a professional engineer registered in Ontario and holds an MBA specializing in management information systems from the York University Schulich School of Business in Toronto and a bachelor of science degree in mechanical engineering from Queens University, Kingston, Ontario.

Patrick Zirnhelt is responsible for IFS’s presence in enterprise asset management (EAM) software in North America. He has more than 22 years of experience working with enterprise systems, which includes software development, implementation and sales. He is a professional engineer registered in Ontario and holds an MBA specializing in management information systems from the York University Schulich School of Business in Toronto and a bachelor of science degree in mechanical engineering from Queens University, Kingston, Ontario.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.