Boston-area company expands advanced manufacturing portfolio to better serve customers.

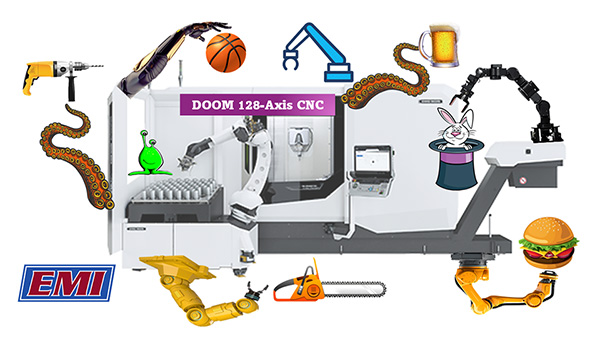

BROCKTON, Mass — Evans Machine Co., Inc. (“EMI”) (www.emievans.com) is now operational with a new 128-axis CNC machine. A world’s first, this machine combines turning, milling, EDM, grinding, honing, several types of welding, polishing, injection molding, casting, a cup holder, 8 flavors of soft serve and more. The new capabilities will allow EMI to continue to bring the most cutting edge technologies for part fabrication, machining and other services to North America’s advanced manufacturers.

Companies seeking the most advanced manufacturing and machining capabilities now have new options to create stunning and intricate parts thanks to Evans Machine Inc’s new 128-axis CNC Turning & Milling Machine. Equipped with an absurd number of spindles, robot arms, end mills, drill heads and an infinite capacity tool changer, this workstation brings unparalleled opportunities for part fabrication.

For over a half century Evans Machine Inc (“EMI”) has supported the many high-tech industries of the Boston / New England area. From silicon chips and computers to defense and clean energy, from medical and biotechnology to robotics and oceanography, EMI supports the high-tech industrial clusters and entrepreneurial base fostered by the area’s many leading universities and research institutions.

“Continuing to push the envelope on offering new capabilities to our customers is in our DNA. We’ve long had a line item in our budget where we have to spend a certain amount of capital on new equipment each year,” said Dan Evans Jr., president and owner of the company. “This new machine is the latest in a long line of investments we make to bring the latest machining technologies to our customers.”

According to Tom Roach, EMI’s Operations Manager, “We already have 5-axis machines producing world-class parts for our customers every day. We’re always thinking about the future of manufacturing, so we looked at next-level advancements such as 7-axis machines. But we felt the ability to shape parts in only the X, Y, Z, A, B, C, and E axes would be overly restrictive, so we decided to pull out all the stops and invest in the next- next- next- next- next-level capabilities you see here today.”

Gesturing proudly toward the new contraption, Tom continued, “We’re big on nicknames here. It’s a fun way of creating a real sense of comradery so, in recognition of the 128 axes, we nicknamed our newest baby the Double-Octo-Octopus Machine or ‘DOOM’ for short.”

Of course, the year is 2025 and no topic is hotter than Artificial Intelligence. Unsurprisingly, the DOOM machine has AI integrated into everything it does.

According to Dan Evans Jr., “Frankly, we’re not sure what a lot of these axes actually do. There does seem to be a predictive time travel component to the AI because sometimes the machine turns itself on and completes the parts before we’ve even received the RFQ, much less the Purchase Order.” With a shrug of his shoulders, Evans continued, “While this is a bit mysterious, we are not complaining because the result is a streamlined order and production process, which really reduces turn times for our customers.”

“While we are excited to discover more of what the DOOM machine can do for our customers,” enthused Tom Roach, “we are just as excited about integrating palletized stock feeding.”

“Yes, the quantum physics are sorta tricky, but we think we can integrate an infinite number of stock feeding mechanisms by linking DOOM to one or more pocket dimensions in parallel universes. We’re working on this problem with teams from MIT, Bridgewater State University and Marvel Comics and hope to have an announcement on this by April 1st next year.”

While the 128-axis CNC DOOM machine is the future of manufacturing made present, EMI will continue to forge ahead at the forefront of new innovations for advanced manufacturers.

And, last but not least, happy April Fool’s Day everyone!

About Evans Machine Inc.

Founded in 1968, Evans Machine Inc. is a world-class manufacturer of CNC precision machined parts. With scores of customers across a broad range of industries — including Defense, Food Machinery, Medical / Surgical, Oceanography, Automotive and General Industrial – EMI brings unparalleled expertise in creating parts for advanced manufacturers. A family business, EMI now occupies some 45,000 square feet of manufacturing and warehouse space, including Class 8 wash and clean rooms for sterile packaging, and is planning the next round of facilities expansion. Learn more at www.EMIEvans.com.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.