Injection molding company deploys Robots-as-a-Service for 20% production boost, 40% opEx reduction.

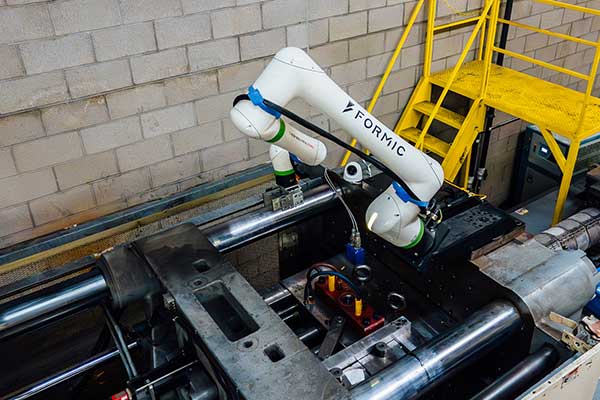

CHICAGO ― Formic, accelerating the adoption of automation across American manufacturing, announces its automation partnership with ICON Injection Molding following the successful deployment of Formic’s Tend™ solution.

Arizona-based ICON Injection Molding, which produces plastic parts for laboratory use and defense equipment for clients like Axon, recognized the need to automate but was unable to overcome the barriers of upfront capital, risk and expertise. The family-owned business sought to reduce risk to its employees from dangerous, repetitive activities that could potentially lead to injury, staff turnover, operational inefficiencies and higher prices for end customers.

ICON chose Formic’s Robotic-as-a-Service (RaaS) offering – a zero-risk approach that provides efficient, on-demand access to automation with uptime commitments and no upfront costs.

From day one of deployment, ICON achieved:

Nicole Kleitsch-Killam, ICON’s Chief Administrative Officer, has been with the company for the majority of its history and knows the barriers to automating.

“From our experience, this is enhancing productivity and increasing safety for employees,” says Nicole. “Generally, there is a barrier to entry for automation because high upfront capital makes it expensive. Automation is not something you can go and buy off-the-shelf, so you have to get a custom solution. As a custom injection molder, we are running different jobs in our presses every day. There are lots of automation companies out there that lock you into something. Formic has given us complete flexibility without locking us into anything – it’s a really symbiotic relationship for both parties.”

Formic’s RaaS solution delivers full-functioning, robotic solutions from leading robotic vendors such as FANUC, Universal Robots, and Yaskawa Motoman to customers who pay by the hour for usage. Formic owns, programs, installs, and maintains the robots at its own cost and operates a unique model in which customers do not pay until the system is deployed and fully operational on a customer’s floor. Additionally, once new systems are activated, Formic covers all the engineering and costs for repair and maintenance and does not charge hourly fees during any downtime.

“Our holistic approach and Pay-for-Productivity model makes cutting-edge automation accessible and simple to SMBs,” says Misa Ikhechi, Formic Co-Founder, VP of Product and Partnerships. “We always put our customer’s best interests first, which means we are technology agnostic. There are other companies offering RaaS services, but they have a single tool and they try to solve every problem with that tool. At Formic, the best solution wins, no matter who makes it.”

About Formic

Founded in 2020, Formic is accelerating the adoption of automation across small to mid-sized U.S. manufacturers and boosting productivity by removing the risk, complexity, upfront capital, and expertise that typically exist as barriers to onboarding this technology. The company’s “Robotics-as-a-Service” model delivers customized robots at a low hourly rate, with guaranteed uptime. With a full service offering that includes everything from planning and deployment to maintenance and upgrades, Formic is creating an innovative and accessible competitive advantage for small and mid-sized factories to ensure they stay relevant and thrive in any economy. Go to formic.co for more info.

Tune in for a timely conversation with Susan Spence, MBA, the new Chair of the ISM Manufacturing Business Survey Committee. With decades of global sourcing leadership—from United Technologies to managing $25B in procurement at FedEx—Susan shares insights on the key trends shaping global supply chains and what they mean for the manufacturing outlook.