The benefits of GFRP (glass fiber reinforced polymer), a material that is very valuable for infrastructural projects in harsh environments.

GFRP reinforcement is a game changer in modern construction. As an innovative material, GFRP fiber has been deployed across various sectors and industries, including civil and industrial construction, agriculture, aerospace, etc. At present, the construction industry faces increasing challenges, such as growing maintenance costs, sustainability, and infrastructure durability. The use of fiberglass for concrete reinforcement represents an attractive alternative to conventional steel reinforcement. So, today we examine FRP properties and advantages of fiberglass reinforcement.

GFRP stands for Glass Fiber Reinforced Polymer, a composite material with unique properties that outperform steel in various applications. FRP is lightweight, thermally and electrically non-conductive, non-corrosive, and strong material. The exceptional properties of composites come from the manufacturing process. GFRP is particularly valuable for infrastructural projects in humid and harsh environments.

While steel has been used as the principal reinforcement material for over 100 years, valued for its strength, GFRP represents a modern solution in reinforcement technology. Composite materials represent an innovation in reinforcement and the range of applications is continuously expanded.

The use of fiberglass in concrete for both civil and industrial projects presents compelling benefits for sustainable and durable concrete construction. Non-corrosive properties and light weight of composite fibers offer substantial advantages:

The key advantage of GFRP reinforcement is resistance to corrosion. While steel-reinforced structures are prone to degradation in high-moisture environments, composite fibers ensure longer service life, which is crucial for:

GFRP-reinforced concrete structures are much more durable and require less maintenance compared to constructions with conventional steel reinforcement, particularly in harsh environments.

The high tensile strength and lightweight nature of composite materials ensure:

Given the non-conductive nature of composite materials, fiberglass-reinforced solutions are ideal for the following applications:

Civil engineers and architects have greater flexibility in construction design:

Despite the initial higher material costs, the long-term economic benefits of GFRP reinforcement are justified thanks to:

The continuous development of environmentally friendly FRP production technologies and implementation of energy-efficient processes lead to:

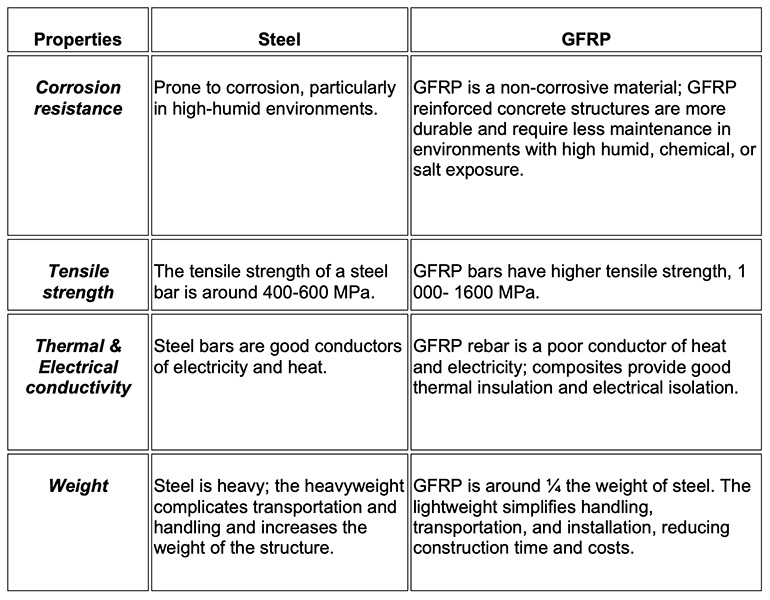

Understanding the key differences in properties of reinforcement materials might be crucial for the durability and cost-efficiency of a construction project. The comparison table below highlights the principal characteristics of steel and GFRP that influence material selection for a specific project.

The FRP manufacturing process has undergone significant technological upgrades. Modern production facilities deploy robotic systems and computer-controlled equipment to ensure consistent product quality.

Advanced technologies, such as IoT sensors and real-time monitoring systems, help to track material properties and optimize curing cycles. Innovative nano-additives and smart resins enhance the mechanical properties and functionality of FRP products. Dedicated software allows predictive modeling of composite properties and behavior.

Quality control is maintained via automated inspection systems, such as thermography and ultrasonic testing. Energy efficiency and cost-effectiveness of the manufacturing process are achieved thanks to developments in molding processes.

The key factor in producing high-quality composites is the manufacturing technology. GFRP production lines from Composite-Tech ensure precision and consistency throughout the fiber production process.

Enter the future of construction with Composite-tech equipment — the innovative technology for strong and durable GFRP reinforcing solutions.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.