Manufacturing is now adopting next-generation file storage technologies reducing time spent maintaining legacy file storage solutions.

by Saimon Michelson, Field CTO, North America at CTERA

The shift to remote work models in manufacturing began well before 2020. As manufacturing practices became more distributed, and their locations spread out, the need for automated IT processes for all these locations became apparent. At the same time, these companies could see that their legacy NAS appliances were not up to the challenges surrounding their file storage, including supporting the sudden, massive remote work model, unprecedented data growth, and increasing storage costs.

Most of these legacy NAS solutions were built to users located at a single location (i.e., the manufacturing floor). But for an enterprise with several locations, the prospect of installing a new NAS appliance at each site can be expensive and cause difficulties in IT management as disconnected data “islands” at different locations can lead to security risks and Shadow IT – data that exists outside of a company’s knowledge, control and security protocols.

The risks once commonly associated with the public cloud are no longer prohibitive and moving data storage there brings with it cost savings and scalability. Yet, using it as a company’s primary storage solution can still raise questions around security and productivity.

The necessity to facilitate file access, from anywhere and on any device, quickly and securely became critically important during the outset of the COVID-19 pandemic. Over the course of 2020, we have seen an important, perhaps permanent change in the way the manufacturing enterprise does business. Workforces are shifting from all-encompassing headquarters to where a majority of the workforce gathers, to work-from-home situations and smaller local offices, to ensure business continuity.

In the manufacturing sector, it follows that as business continues to expand, data storage requirements grow at the same pace. Now, the manufacturing sector has begun searching for options in how it allows corporate file systems to permit remote users with LAN-speed performance, while taking into account corporate security policies and productivity requirements.

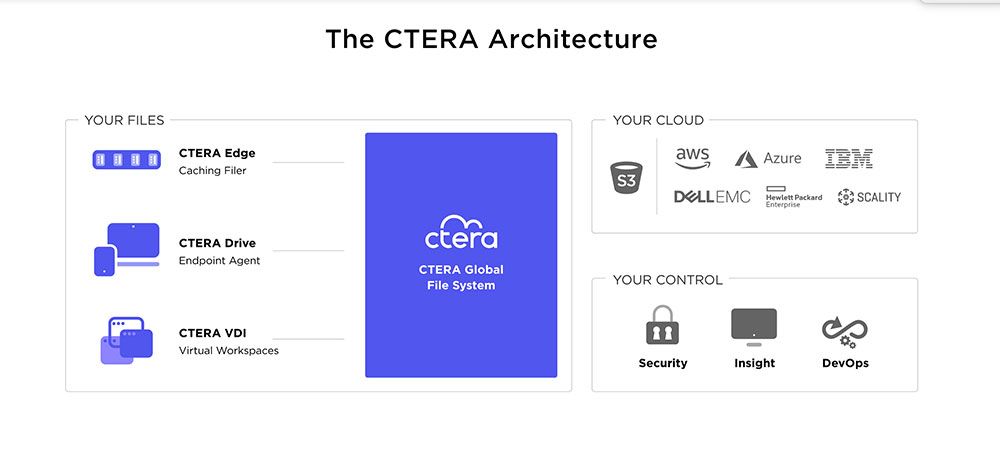

What is required is a hybrid solution that unifies low-cost cloud object storage and fast local access at remote manufacturing sites and home offices. Manufacturing requires both – elastic scalability without any degradation in performance for a great edge computing user experience. This hybrid solution is a Global File System.

A Global File System allows organizations to replace traditional NAS and file storage systems with a modern and secure file services platform.

Global File Systems employ either public or private elastic cloud storage as a central, golden copy of data that is cached to local devices for fast and effective file access. Global File Systems create massive savings, shrinking storage costs by up to 80 percent compared to legacy NAS.

Global File Systems unify corporate data within a single global namespace and bring together edge devices and cloud storage. Their feature sets and access are centrally run and managed. Edge filers perform the file caching the occurs at each remote location. Files are then coordinated between the edge filers and the Global File System.

Additionally, Global File Systems connect offices and locations from any desktop, laptop, VDI client or mobile device, allowing employees to access, share and collaborate on files securely, just like they would at a business’ headquarters. This is important for companies employing remote employees who must have quick, efficient access to data from their devices in order to complete their work.

These Global File Systems are highly secure through private deployments and end-to-end encryption of data. As well, global file systems built with zero-trust architectures deliver higher levels of confidence for organizations’ data privacy and compliance mandates.

Here is look at how some CTERA customers in the manufacturing industry are using the Global File System to meet their file services and remote work challenges.

Churchill (UK)

With file storage requirements increasing by 10-15 percent every six months, ceramic tableware maker Churchill sought a way to lower storage costs, as well as enabling remote access and multi-site file collaboration for its users. Churchill decided to replace its legacy SAN array-based storage services with a hybrid cloud architecture based on CTERA’s Global File System.

In addition to providing infinite storage capacity and simplified data management, the Global File System saves Churchill tens of thousands of pounds on disk storage. Churchill’s Head of IT, Alistair Henderson, discovered another huge bonus following the COVID outbreak. “COVID-19 has made remote workforce enablement a critical priority. Through our work with CTERA, we’re able to enable seamless file access and collaboration for WFH users, making them as productive as if they were in the office.”

Festo (Germany)

Festo is a world leader in industrial automation technology. The company, based in Germany, has over 21,000 employees located all over the world in 170 locations, and needed a new and effective way to modernize its file services infrastructure to bridge the edge-to-cloud gap for its worldwide locations. Remediation of bandwidth and latency issues were the priorities at Festo. CTERA helped close the gaps the company was experiencing and provided what Marcus Masching, Head of IT Computing Services at Festo called the “the best user experience.” Today, Festo has more than 50 locations running cloud-based CTERA edge filers, supporting locations from 5 to 5000 employees at a time, all over the globe.

“CTERA helped us transform from local on premises infrastructure to scalable cloud-based services reducing costs and TCO,” said Masching.

Global File Systems present an opportunity for IT organizations to address the changing requirements for data storage and data access. New paradigms of unlimited scale with local data access present IT with the best of both worlds approach between cloud hyperscale and on-premises NAS. Global File Systems provide new opportunities to facilitate efficient global collaboration within organizations and represent the future of file storage in the enterprise.

Saimon Michelson

Saimon brings over 10 years of experience in IT, storage and cloud solutions. Saimon has held positions across several functions within CTERA, including product management, sales engineering and software development. Previously, Saimon designed software solutions for the IDF recruitment arm. He holds a BSc in Mathematics and Computer Science from Tel-Aviv University.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.