The CHIPS and Science Act will alleviate supply chain disruptions, just not right away.

By John Ferguson, CEO, TBM Consulting Group

Imagine if all the semiconductor chips your manufacturing operation needs were produced and widely available right in your own backyard. No more worrying about shortages, long order lead times, transit times and shipping delays, or exorbitant transport costs. No more tying up capital in safety stock and excess inventory to safeguard against the next global disruption. No more losing sleep over the escalating geopolitical tensions between China and Taiwan, two leaders in chip manufacturing, that could once again shut off access to critical components.

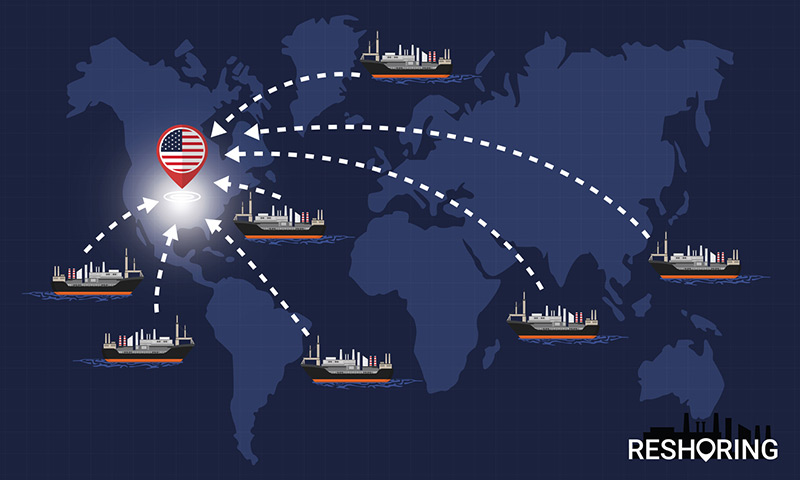

For many U.S. manufacturing companies that have been plagued by chip scarcity over the past several years, this sounds like a dream come true. And, in theory, this utopia is precisely what the CHIPS and Science Act of 2022, signed into law in August, is intended to create. The law aims to reshore chip manufacturing and position the U.S. as the leader in the semiconductor industry for decades to come.

While the new law will reduce dependence on the Asian semiconductor market, realistically, it will be several years before new U.S. chip manufacturing facilities can be built, workers can be trained, and production can be up and running here at home. Even when the plants are operational, it is likely that they will be current or next-generation fabrication sites that produce high-end, advanced chips.

This is great news for companies that rely on those types of cutting-edge chips. And it is great news for the United States overall. The act will decrease reliance on other countries for our most critical and sensitive semiconductors, thus protecting our intellectual property and boosting national security while securing our country’s spot and ability to operate at the forefront of innovation and technology.

However, the majority of manufacturers that rely on older, commodity-type chips for their toasters, alarm clocks, children’s toys, and other everyday products will not likely see any benefit through increased supply. Hence, most of the supply shortages that directly impact consumers will not be impacted at all.

What this means is that U.S. manufacturers must remain vigilant about doing everything they can to mitigate supply chain risk and ensure access to the components they need right now. One of the most effective ways to do this is to diversify their supplier base. In the near-term, companies need to look at options they can leverage immediately to build more resiliency and flexibility into their supply chains. This includes splitting chip spend between several suppliers who are ideally located in different parts of the world to safeguard against disaster or delay in any one region.

Of course, supplier diversification is sometimes easier said than done, and such a strategy still takes time to execute. Another faster and somewhat simpler way for manufacturers to help themselves is by conscientiously helping their suppliers. Companies that focus on being good, reliable, consistent customers through better planning, forecasting, and communications with their business partners are the ones that are favored when suppliers face constraints and use allocation to serve their best and highest-priority customers. With inflation soaring, better demand, production, and supply chain planning has the added benefit of freeing up working capital and reducing inventory carrying costs.

While such supply chain strategies are becoming essential to operating in today’s volatile geopolitical and difficult economic conditions, these are smart business practices in any environment. Companies that prioritize supply chain flexibility and strong supplier relationships now will be well positioned to apply such practices to their new relationships with both existing suppliers and new U.S. based semiconductor suppliers once they come online. Those with the best practices in place will be able to capitalize on the benefits and advantages even faster than their competitors.

The bottom line? The CHIPS and Science Act promises great benefits for U.S. manufacturers in select industries, but it’s not likely to impact the majority of chip related supply shortages. So, while some companies can expect easier access to chips in the future, there is still supply chain strategy work to be done now by all companies to keep their production lines and operations running smoothly and profitability.

John Ferguson is the Chief Executive Officer of TBM Consulting Group, where he brings a wealth of experience as an executive leader in operations and supply chain management with deep background running international operations. He has expertise in operations and supply chain management with hands-on experience leading all elements of project engagements, including: strategic assessments and diagnostics, process re-engineering, go-forward plans, implementation, internal and external communications planning, metrics and integration of enabling technologies. John also serves as Chairman of the Board of Directors.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.