Flying S improves accuracy / reduces retention knob failure via standardizing JM Performance Products’ high torque retention knobs.

Fairport Harbor, OH:

More than most industries, aerospace component manufacturing machines a lot of exotic alloys and hard metals like titanium. A byproduct of utilizing these materials is that more pressure is put on the machines, spindles, and retention knobs. The end result is that the tools must be changed out more frequently as they dull or break. The cost of tool replacement, not to mention loss of production time due to frequent changeover, can escalate costs as well−often to dizzying levels.

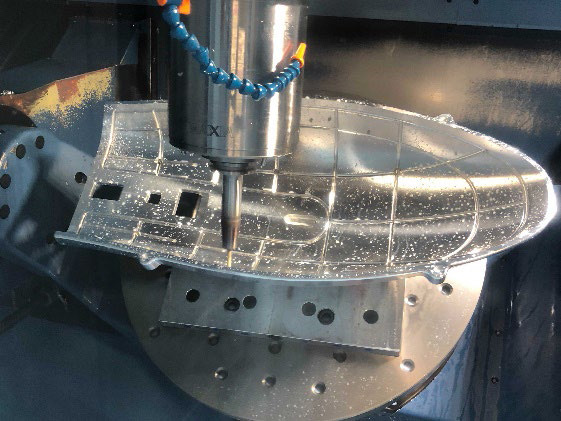

Recently, Flying S, Inc. (Palestine, IL), a high-quality parts aerospace/aviation industry focused engineering company since 2001, continued its expansion to more palletized five-axis machining center technology to handle the high-volume production precision machining of complex, tight-tolerance parts out of titanium, stainless steel, and other difficult to machine materials. Notably, as the five-axis parts they made for unmanned military and civilian aircraft, along with spacecraft, became more complicated, it became clear that greater machine capability was needed to achieve reliable, unattended operation.

According to Manufacturing Engineer Peter Bowman, “Many of our space flight fittings require tight-tolerance features. Our lack of reliable positional accuracy and repeatability due to thermal growth, machine positioning or other variables, really took a toll on our efforts to consistently make a good First Part, and subsequent parts after that.”

With new five-axis CNC machining centers in place, including state-of-the-art models from Matsuura USA (St. Paul, MN), and Brother Industries, Ltd. (Nagoya, Japan), significantly higher torque and drawbar pressure was being exerted on their standard, low cost retention knobs causing issues with the interface between the toolholder and spindle. Consistently, standard retention knobs were coming loose as dimpling/grooving wear issues repeatedly appeared on the face of the knobs−thus requiring replacement on a regular basis.

Whereas machining is about eliminating variables, Flying S actively sought out a solution to resolve their retention knob issues. During a visit to IMTS (International Manufacturing Technology Show, Chicago, IL), Bowman witnessed an expanding taper demonstration by JM Performance Products, Inc. (JMPP: Fairport Harbor, OH), which featured their patented High Torque® retention knobs. Uniquely, the knobs were designed and engineered to eliminate the toolholder expansion responsible for costly and ongoing CNC milling and boring issues.

A leading manufacturing innovator of CNC mill spindle optimization products since 2009, JMPP’s retention knobs feature a relief beneath the precision pilot that forces the threads of the knob deeper into the threaded bore of the toolholder–where a thicker cross-section of material resists the expansion and deformation.

With their multi-axis and unattended operations expansion commitment in full force, Flying S set out to standardize their entire line of CNC machines with JMPP’s retention knobs, in order to overcome catastrophic failure as a result of metal fatigue and other high load force related issues associated with difficult to machine materials and long tooling.

Today’s CNC mills, like Flying S’s multi-axis machining centers, are designed to operate with greater draw bar pressure, faster tool changes, higher feed rates, and greater depths of cuts, which places more demand on retention knobs in V-Flange tooling than ever before. Flying S was able to address the following key issues via JMPP’s retention knobs.

Titanium Challenge: Superalloys / exotic materials such as stainless steel, aluminum, and titanium are on the rise for component manufacturing in vital growth industries such as aerospace, medical, and automotive.

Considering that high speeds typically in excess of 20,000 RPMs are often required, a unique set of production machining challenges ensue. Notably, vibration and chatter can occur at these rates of speed, leading to poor surface finishes that require secondary bench operations, or result in critical damage to expensive workpieces.

Stability is an essential factor for improving milling performance on demanding materials like titanium–as the entire machining process has to be considered. Any one element could impede the overall process’s effectiveness as the tool, toolholder, spindle, column, ways, table, fixturing, and workpiece are all part of the interconnected ‘machining circle’ that requires stability to achieve optimal results.

Retention knobs are the critical connection between your machine tool and the tool holder, and they are the only thing holding a steep taper tool holder in the machine’s spindle. However, often times retention knobs are overlooked by many shops, with a greater focus placed on having a high-quality machine tool, top of the line tool holders and the latest high performance carbide tooling. Then, ironically, they will break the loop by using economy retention knobs.

Notably, they go through thousands of tool changes which means they are subjected to the very high pull forces from the spindle’s drawbar. Excessive torque tends to swell the metal around the retention knob, distorting the toolholder and creating a less-than-perfect fit between it and the spindle taper. Additionally, toolholder expansion caused by standard retention knob installation can reduce the toolholder to spindle contact by 70% or more. It’s no surprise that many machine tool builders specify the use of high-quality retention knobs for best performance.

Yet, just having an expensive retention knob does not mean better performance. JMPP redesigned the standard retention knob into its patented High Torque retention knob which uses the lowest available threads in the toolholder. The pilot portion beneath the knob flange above the threads stabilizes the knob in the toolholder. The High Torque design includes a precision ground pilot, that ensures the perfect alignment of the knob in the holder during installation.

JMPP also manufactures all 30 and 40 taper retention knobs, including the patented High Torque knobs, from AISI 9310H material–offering 40% more tensile strength, instead of the traditional 8620H material.

Deep-pocket drilling of exotic materials, like titanium, requires more coolant that acts like a high-pressure garden hose. This Through-Spindle Coolant (TSC) runs through a hole in the knob, which allows the coolant to run through the tool to the tip of the drill, and thus helping to achieve heavier cuts, higher feed rates, deeper holes, and better surface finishes. It is often used for drilling into tougher materials like the ones used by Flying S in their aerospace applications. It also allows for better chip evacuation by forcing the chips out of the hole, thus improving process reliability.

As one can imagine, putting a hole in the center of the knob where the coolant runs through can cause major issues when using economy retention knobs since they are made from weaker materials. Often times TSC retention knobs are where failures occur because of this design characteristic.

JMPP’s longer length and shorter threads means less torque value and more leverage on the holder for high-pressure TSC−with less fretting on the holder or vibration. The size of the coolant holes has also been be sized to increase the cross-sectional strength of the knob.

Bowman noted that, “We use JMPP’s knobs as standard for both TSC and non-TSC applications across the board because there is no need to swap them out when using TSC. It’s a safety measure for us. We would rather standardize so that ALL retention knobs are TSC capable, thus reducing the chance of trying to run high pressure coolant on a non-TSC knob, thus flooding our spindles. What we found is that the knobs handle the force on the holder exceptionally well with no leaks at 1K psi, and no signs of excessive wear.”

With the expansion of more state-of-the-art multi-axis machining centers, Flying S has implemented a standardization plan to exclusively utilize JMPP’s retention knobs. To date, they have roughly 2,000+ retention knobs in their shop’s operation including and featuring the following tool tapers:

CAT 30: Flying S currently uses BT30 TSC High Strength knobs in their Brother M140 and M200 machines. These are small spindle, high production 5-axis machines, typically with longer tooling requirements and robotically loaded, so the retention knobs work extremely hard, thus far with zero issues reported. See picture of the 3 “Brothers” below.

CAT 40: The majority of Flying S’s tooling is CAT40, so it is midsized. They use these retention knobs in their 5-axis Matsuura and Haas products. Some of these machines by name are the Matsuura MAM72-70v 18 pallet, MX-850 4 pallet, MX-520 4 pallet, and MAM72-25v 40 pallet. Haas would be UMC-750 5 axis and numerous other vertical machines. According to Bowman, “To date we’ve had no issues, as far as I’m concerned, and will only use JMPP knobs going forward.”

CAT 50: Flying S just purchased their first CAT50 machine, the Matsuura MAM72-100H−the largest 5-axis that Matsuura makes. The MAM72-100H is a beast, boasting a 6 pallet system, 245 tool magazine, horizontal 5-axis machining center with 1000mm of pallet swing. According to Bowman, “We will essentially be able to machine a 2 ½ ft square cube of stainless steel if we wanted to, which is wild. This machine will also use JMPP’s knobs exclusively.”

Machining complex parts is common in the aerospace and energy industries, with more companies investing in multi-axis machining centers that can match the demanding production challenges they face. As Flying S grows, they continue to invest in more advanced machines. As a result, they continue to see the value in having the right tools to protect and get the most out of those machines.

By implementing over 2,000 of JMPP’s High Torque retention knobs, every tool on Flying S’s machines works better and faster to make their demanding projects more competitively, reduce machine down time, extend tool life and increase profit margins.

According to Bowman, “We were finding ourselves replacing the older $11 knobs on a regular basis. However, I have never replaced a single JMPP knob! Our standardization investment is great and I think it will last.”

Flying S has recently implemented an annual Preventative Maintenance Plan for all of their machines that uses JMPPs’ hydraulic Clamp Force Gage Fixture to regularly check the clamping/pulling force of the drawbar. Drawbars are a high wear item in CNC machines and often overlooked as equipment ages.

As part of this program, they also use JMPP’s advanced Spindle Cleaner Kit that is designed to clean CAT and BT spindles in 30, 40, or 50 taper sizes.

Bowman also noted, “We also rented their Taper Shank Test Fixture that we saw at the IMTS show to prove to ourselves, and management, that we needed JMPP products. The test was pretty shocking and very convincing. We had no idea how much our “economy” retention knobs were costing us!”

For more detailed information contact: www.jmperformanceproducts.com

CORPORATE PROFILE: Established in 1966, JM Performance Products, Inc. (JMPP) has firmly established itself as a leading manufacturer of CNC mill spindle optimization products. Across a myriad of markets, JMPP is dedicated to reshoring with over 500 styles of patented Retention Knobs for BT, DIN, ISO, and CAT toolholders from 30 taper to 60 taper−all manufactured and material sourced in the United States! All products in the integrated suite are engineered to optimize milling machine performance including: improving finishes, eliminating run-out, reducing chatter and harmonics, decreasing set-up times, extending tool life, and increasing spindle performance.

Author: Craig A. Fischer / JM Performance Products, Inc. / 440.357.1234 / cfischer@jmppinc.com

Editorial & Photo Contact: Ray Farrar / Method Media LLC / 216.861.0862 / rayf@methmedia.net

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.