Industrial companies that transform their business model to EaaS are better equipped to weather operational disruption.

Events impacting the global business landscape over the past two-plus years have revealed the interconnectedness of industry, particularly on a global scale. While this interdependence can spur innovation, create efficiencies in production and help grow small businesses into large enterprises, it has also underscored the need for business leaders – especially in the manufacturing industry – to build greater levels of operational resiliency against business disruptions.

The idea of enhancing operational resiliency speaks directly to fortifying business practices to ensure your organization is better equipped to navigate difficult, uncertain, and sometimes even volatile market conditions. It’s about transforming your business to breed greater levels of consistency, improve customer intimacy, elevate revenue generation, and provide value to both the customer and provider.

One way to accomplish these goals is by implementing a subscription-based business model, like Equipment-as-a-Service (EaaS). With EaaS contracts, rather than being purchased once via a single costly expenditure often financed over time, machinery and equipment are rented for a fixed period or to meet other pre-determined outputs. Innovative pay-per-use or pay-per-unit-produced business models enable providers to develop customized, user-friendly solutions that meet their partners’ goals.

Subscription-based models popularized by the software industry have already made their way into industries like manufacturing, with the EaaS market forecast to grow with a CAGR of 11.5% between 2021-2027.

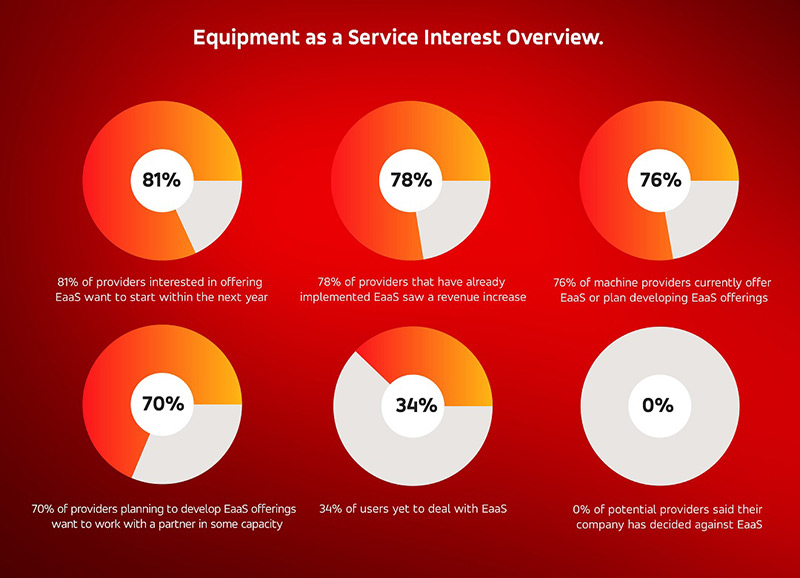

A recent study we conducted found 76% of US manufacturing executives surveyed either currently offer EaaS or harbor plans to develop an EaaS model, with 81% of those wanting to explore this shift within the next 12 months. Respondents cited improved resiliency against crises as one of the top three benefits of implementing the model.

EaaS business models create and enhance resiliency against disruptions for manufacturing organizations in several ways that range from tangible cost savings to intangible impacts on business relationships.

Professionals in the manufacturing sector will agree that most repairs are typically less expensive than the loss of income from machine downtime. A foundational element of the EaaS model is that responsibility for maintenance and repairs fall upon the provider, ensuring partners are up and running with zero interruptions.

In addition to maintenance and repair costs, operational expenses become more predictable and stable through EaaS by eliminating large up-front costs of machinery and shifting from capital expenditures (CAPEX) to operating expenses (OPEX). Rather than a one-time sale or purchase every 20-30 years, consistent connection made through EaaS helps to improve overall operations, machines, and relationships.

Aside from reducing costs, EaaS also has the ability to open up new opportunities for revenue growth for OEMs and servicers alike. Offering subscription options that are compatible with a customer’s financial resources helps turn stagnant equipment and inventory that would otherwise go unused for a period of time into long-term, recurring, and predictable streams of revenue.

Predictability also breeds benefits in terms of access to spare parts, allowing both the supplier and their partners to keep lower volumes of inventory on premises, freeing up valuable storage space. By diversifying production and freeing up space, the shop floor becomes more efficient and bolsters a company’s resiliency against unplanned and unpredictable market conditions.

Risk is an inherent part of doing business. The EaaS model can help mitigate the effects of unexpected events or conditions by providing users with unprecedented opportunities to gain a clearer picture of how their production line is performing before things go wrong.

One of these opportunities is remote equipment visibility. Always-on, consistent monitoring of machinery leads to predicting when a machine is likely to experience failure and break down. Valuable data collected through predictive maintenance (PdM) indicates what repairs should be made and what parts need to be ordered well ahead of time to avoid any supply chain hiccups and dreaded machine downtime.

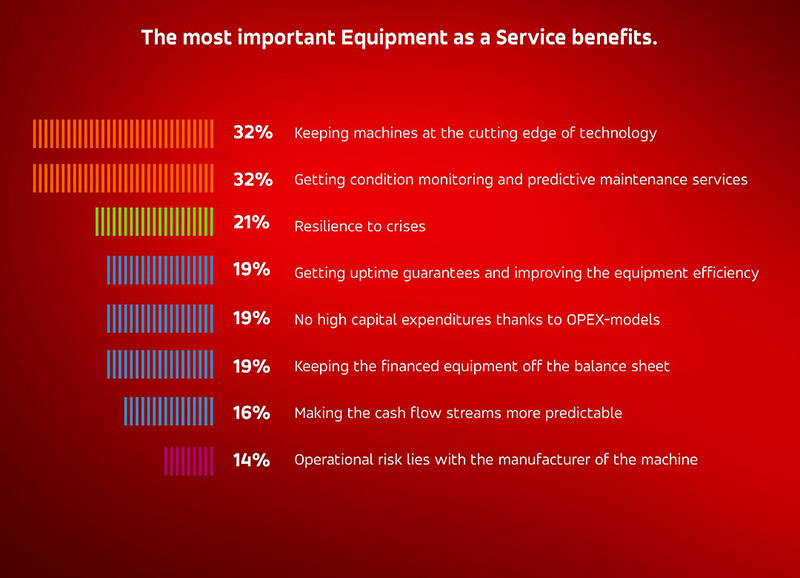

Insights from constant, real-time, proactive machine performance monitoring throughout the production process can also reveal opportunities for product improvement, which can give a leg up on competition. In fact, 32% of the US manufacturers surveyed in our study agree keeping machines at the forefront of technology is a major benefit of EaaS.

Perhaps one of the most important benefits of EaaS that can be the difference between a renewed contract and one that is terminated during a market downturn is increased partner intimacy.

Traditional provider-partner business models rely on a one-time purchase that yields little value after the deal is done. With EaaS, providers and their partners develop an ongoing business relationship throughout the life of the contract, leading to a greater level of empathy and understanding of both parties. In fact, 38% of EaaS providers say the most important benefit of EaaS is building more durable relationships with their business partners.

By building and maintaining these relationships through repairs, improvements and site visits, there is a sense of partnership that is established that can prove invaluable when contracts are due for renewal, especially after a challenging year. This increased level of partner intimacy leads to longevity, and that certainly helps build resiliency.

Given the lessons learned over the past few years, it’s clear the business community requires a mindset shift to continue addressing challenges in the future. Through EaaS, organizations can overcome the complex business challenges of today and tomorrow by recognizing key benefits and becoming operationally resilient.

About the Author:

Jessica Poliner is the CEO and President of relayr, an Industrial Internet of Things company focused on solutions for risk-free digital transformations.

Visit www.relayr.io for more information.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.