As worker productivity is at the forefront of manufacturer’s minds, read how IIoT data can accelerate productivity on the factory floor.

For the vast majority of manufacturers, a three to five percent improvement in productivity probably sounds really good. Given industry trends over the past decade, anything more would be great. And 25 percent would be phenomenal. While 25 percent may sound unrealistic, with smart use of Industrial Internet of Things (IIoT) data, double digit gains as high as 25 percent are not outside of the realm of possibility.

Manufacturers can use IIoT data in three primary ways in pursuit of high productivity, including monitoring performance, relying on timely alerts, and performing analytics-based productivity analysis and problem solving. Given the availability and costs of IIoT technology, the barriers to entry are low. Success, however, is not guaranteed. To see good or even double digit returns, manufacturers need to be smart and deliberate about how and where they rely on IIoT sensors and data to drive productivity.

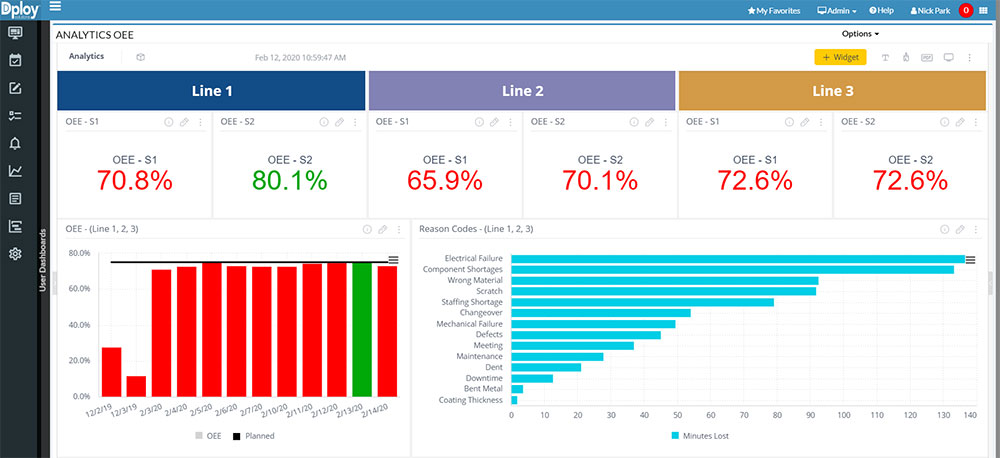

Dploy Solutions software showing overall equipment effectiveness monitoring.

Effectively using IIoT data to drive productivity is all about tracking and optimizing overall equipment effectiveness (OEE) or overall operating efficiency (OOE), depending on organizational preferences. While different manufacturers and organizations calculate OEE or OOE in different ways, they focus on three primary key performance indicators (KPIs).

In all cases, when a process is underperforming vis-à-vis a primary KPI, there is a direct impact on productivity whether a process is running slower than it could or should, materials are being scrapped or work needs to be redone. Through a focus on OEE and consistent performance monitoring, employees can continually work on getting each area—along with productivity—as close to perfect as possible.

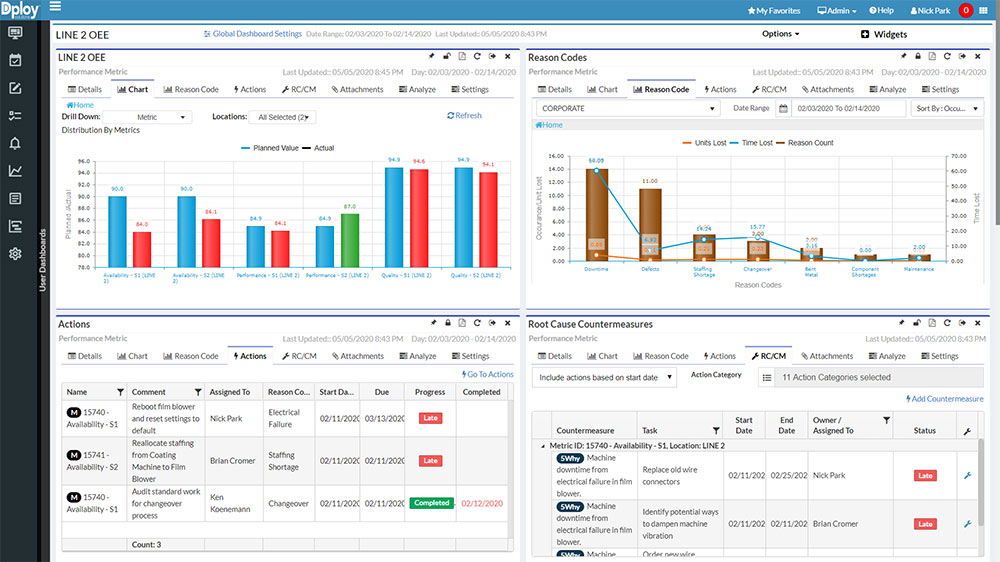

Dploy Solutions software providing KPI measurement around availability performance and quality.

It’s important to keep in mind that figuring out what really matters to measure in each area is often challenging. Since success depends on a clear understanding of the actual root causes of issues, it’s important to rely on rigorous analysis. That’s why for manufacturers pursuing IIoT initiatives, the Lean Six Sigma methodology is well worth considering. Between the Y = F(X) formula and the concept of Define, Measure, Analyze, Improve, Control (DMAIC), Six Sigma can provide effective “guardrails” for IIoT initiatives and help answer:

Once an organization defines the most important parameters for availability, performance and quality, manufacturers can put IIoT data to work in pursuit of higher productivity. But doing this effectively often requires a delicate balancing act. The problem is that too much data and too many alerts become noise. Operators will ignore alerts that they feel are false or they can’t do anything about. Or an overwhelming amount of data and alerts may actually further hinder productivity. The right alerts at the right time should deliver clear improvements in availability, performance or quality. When employees can see the value of the alerts to the business and their role in improving OEE, it can also help incentivize better teamwork and problem solving.

Over time, manufacturers can use analytics on IIoT data to perform deeper analyses and uncover new opportunities for improving OEE and productivity. For example, relying on historical data, it’s possible to explore how trends in performance and quality parameters may have led to bad parts or rejects, or to analyze the root cause of productivity issues. Armed with these insights, factory supervisors and teams can fine-tune workflows and establish action plans to improve process or machine effectiveness.

Vendors and thought leaders have different schools of thought for how to leverage IIoT sensors and data to improve manufacturing operations. Many argue that it’s a good idea to put sensors on nearly everything and collect as much data as possible. In reality, however, the types of data and alerts that will be useful to driving productivity in most manufacturing operations are limited.

The most effective way to take advantage of IIoT capabilities and data in pursuit of productivity gains is to start small with a narrow focus on critical parameters. Expansion should come only after teams see positive results and identify new opportunities with strong potential to drive further improvements. For manufacturers that have a lot of IIoT data but are still struggling to increase productivity, the key is to shift focus to OEE KPIs and use analytics to zero in on what’s most important.

Keep in mind that some parts of the IIoT journey are more complicated than others. For example, setting up an alert for a tolerance parameter slip is relatively straightforward and easy. Predictive alerts, however, require more advanced modeling capabilities as well as a baseline of data for a combination of parameters. That’s why it’s important to stay realistic about the types of projects that make sense based on current capability levels.

Ultimately, IIoT data can definitely help manufacturers get out of ongoing productivity ruts. With the right strategy, the gains could even run into double digits.

Ken Koenemann

Ken Koenemann is the VP of Technology and Supply Chain Practices for TBM Consulting Group which includes Dploy Solutions. After joining the company in 2006, Koenemann has been responsible for driving TBM’s technology strategy, creating value-added technologies and services for client business operations. Koenemann is widely recognized for his expertise in translating lean principles to supply chain and customer-facing processes in manufacturing and service organizations. He has a Bachelor of Arts degree in management from the University of Missouri-St. Louis.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.