By Glenn Hensley, IT Infrastructure Manager, Makino.

Digital transformation initiatives are reshaping manufacturing, and here at Makino, a global leader in metal cutting and manufacturing technology, we’re looking forward to advances that allow real time data analysis to better predict machine downtime, track performance, and anticipate maintenance needs.

We build manufacturing tools for almost every vertical, and also offer a suite of Industrial Internet of Things (IIoT) applications that enhance user experience and efficiency, reduce machine downtime, and enable shop managers and operators to easily monitor and control electrical discharge machining processes.

Data is the lifeblood of our global business, which spans locations in Europe, North America, Japan, and other regions of Asia, so we need a robust, efficient manner to synchronize massive amounts of data for our machine specs and schematics. After all, you can only be as agile as your data infrastructure allows, and agility is critical in manufacturing today, so infrastructure performance is key, particularly when it comes to the global network that binds our locations into a seamless digital enterprise.

Our MPLS network wasn’t going to meet our ambitious digital transformation goals, so we went looking for an alternative, and found what we needed in Aryaka’s Global SD-WAN solution. Aryaka not only helped us address a pressing performance need, but also will be the foundation element that supports our aggressive plans to migrate to the cloud.

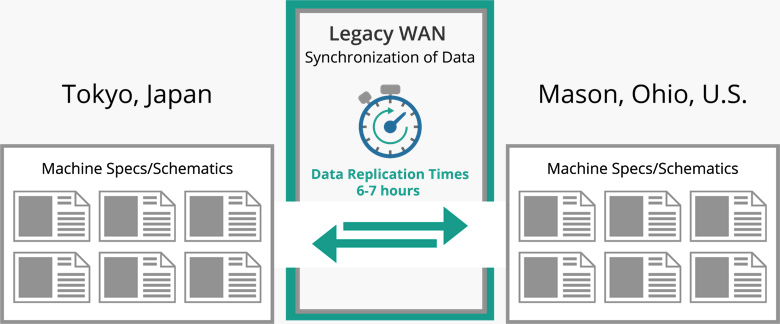

As a global leader in machine manufacturing equipment, Makino transfers giant data files of machine statistics, schematics and drawings to ensure our products meet customer standards. But with our MPLS network, it was taking 6-7 hours to synchronize data between our Tokyo headquarters and our tech center in Mason, Ohio.

Given the time requirement, most of the data transfers had to be done overnight, and there were occasions when the process would not be completed when U.S. employees started their work day. Besides being a constant drain on operational efficiency, if there were any changes to the specs it would mean a one- to two-day delay in production. The network limitations also limited our ability to provide customers with on-demand data relevant to their machines.

What’s more, our previous network was not scalable. MPLS deployment times are notoriously long because circuits have to be coordinated with multiple carriers all the way down to the last mile, creating months of delays in new site rollouts and reducing our ability to set up new locations quickly.

What we needed, and what we found in Aryaka’s Global SD-WAN service, was a carrier-type solution that could link our remote locations without dedicated MPLS lines or reliance on older, high-latency VPN technology.

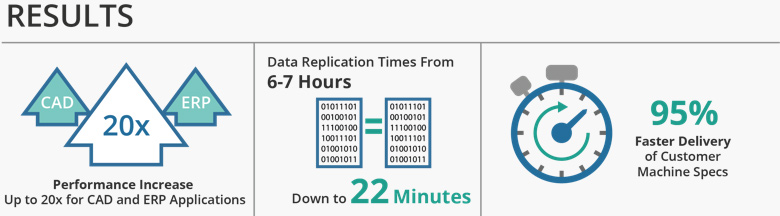

Aryaka was the only solution that provided a significant performance increase from our headquarters in Japan to our sites in North America, due to the fact that the company’s Global SD-WAN service is optimized using de-duplication and caching technologies. With Aryaka, Makino was able to completely replace MPLS with a cloud-native SD-WAN.

Engineers at Aryaka went out of their way to understand our needs and how to address them. We were up and running with testing in 24 hours, and Aryaka provided an in-depth knowledgebase through their support team that quickly addressed any support needs that arose.

Makino wasn’t looking to save money, as we already had the budget allocated for future expansion. We had been paying $1,200/mo. for a 10Mbps MPLS circuit that took months to deploy. With Aryaka, we were able to get twice the bandwidth for the same cost, and we deployed in a fraction of the time. Essentially, Aryaka provided us with far more “bang for our buck.”

With Aryaka, those overnight data synchronization efforts went from 6-7 hours down to 20 minutes. Today we can provide customers with machine tool information and pricing much faster, which helps us win business, and we can be much more responsive, which has opened up new possibilities for growing our business. If that growth requires network changes, we can now modify the network in two or three days, compared to the weeks or months it would take with MPLS.

Needless to say, feedback from executives has been stellar, particularly because the Aryaka Global SD-WAN will support the next major step in our digital transformation strategy, where we migrate 90% of our data and applications to the cloud in the next year. Aryaka will provide accelerated access to any application, anywhere, on-premises or cloud. We now have the infrastructure in place to handle the cloud migration and deliver data and applications to every end user as if it lived in a local datacenter.

Having that high-performance, agile data platform supporting our global locations, ensures that Makino can meet any challenge that transformation in the manufacturing sector presents.

Get to learn more about what Makino has done with their Global SD-WAN solution. Watch our On-Demand Webinar with Lightreading’s Security Now on SD-WAN Best Practices for Application Delivery and Multi-Cloud Security or download the case study today.

About Glenn Hensley

About Glenn Hensley

Glenn Hensley is the IT Infrastructure Manager for Makino, a global leader in Manufacturing technology development, and oversees North America operations for network security and data delivery over the enterprise WAN. Glenn has over 15 years experience developing network configurations for companies such as Hewlett Packard, Proctor & Gamble, Time Warner Cable, and General Electric.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.