In an industrialized world, automation is seen as the road to productivity & profit. But we should also consider the human lives it saves.

The automation of the workforce can be a positive change for people who work in dangerous industries. By definition, automation uses smart systems and computer technologies to handle different processes without any need for manual intervention.

However, the concept is usually met with fear and concern. Employees fear their jobs will be rendered obsolete while employers carefully weigh the initial investment costs vs the long-term benefits. Still, whether we like it or not, automation is happening across all domains and industries. Furthermore, it can provide a serious competitive advantage to early adopters and can help reduce work-related injuries and accidents. Smart machines can also help improve productivity and change the way we think about workers in heavy-industries.

In short, allowing machines to take over some of the most dangerous aspects of the work life is not a bad thing. In fact, like with every type of change, there are two sides to the coin. And, since we already know the dark side, today we’ll have a look at the positive aspects.

A study by Injury Claim Coach managed to highlight one of the main benefits of automation – saving human lives.

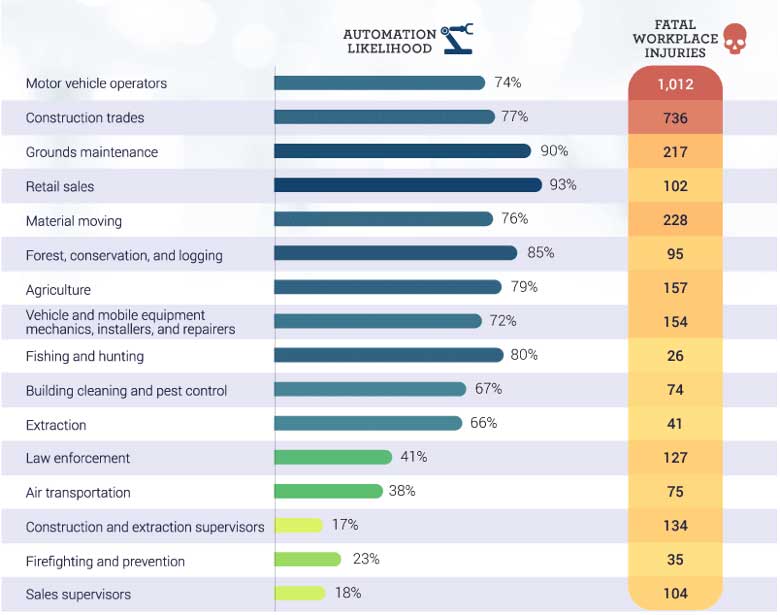

According to this study, industries like motor vehicle operations, constructions, grounds maintenance, moving of materials, and others on the same note are most likely to be automated. These industries also have a higher rate of fatal workplace injuries.

Saving lives through Automation – Industries with the highest rate of workplace injuries and the likelihood of automation.

As a direct result, automation will lead to fewer people in dangerous jobs, which means a lower rate of fatal workplace injuries.

According to the aforementioned study, by 2030, we could save over 3,000 human lives in the US alone by reducing human involvement in dangerous job positions.

The example that speaks loudest about the potential of smart machines comes from the automotive industry.

Each year, we lose about 1.35 million people in road crashes and about 20 to 50 million suffer non-fatal injuries, which may result in long-term disabilities. However, these numbers could be significantly reduced by the adoption of self-driving cars on a large scale.

The same can be said by other industries, where people work in unsafe environments. Let’s take the moving of goods and products for an instance. Human forklift operators are prone to mistakes induced by tiredness, health issues, or good-old distractions. It can happen to everyone as our brains were not designed to strive on repetitive work.

This is where automation comes in and saves the day. Automated forklifts don’t get tired (may need maintenance though) and are carefully controlled by highly advanced systems that map out the access paths. As a result, there is less room for error and more room for improvement.

Amazon is one of the companies that showed us how people and robots can work together in an environment that’s safer and better organized. Their warehouses use smart robots to deliver packages to the right delivery point and humans are there to help speed up the process without endangering themselves or others.

Of course, automation also means an increase in workflow and productivity, since unmanned sections don’t require that many safety protocols and regulations.

Furthermore, the introduction of smart robots can help solve the personnel problem. This is acutely felt in the construction sector, as it gets more difficult to find people willing to work in high-risk jobs that don’t pay well.

Speaking of constructions, advanced technologies have a powerful role to play in the development of this sector. For instance, we could use Virtual Reality to train new employees in a safe and efficient manner. We could also use unmanned drones for high up work and keep workers off the scaffolds. Lastly, smart technologies in combination with 3D printing techniques can help create new materials and more eco-friendly structures.

Lastly, one of the main benefits of workforce automation is speed. Automated machines work faster and have better precision than humans ever could. They are also not bothered by repetitive tasks and don’t require too much time off.

As we already stated, the current technological revolution has a lot of benefits. However, there is one big downside – people will lose jobs. Sadly, there is no way around it.

Still, this doesn’t mean there won’t be other opportunities. For instance, there are countries where people can take classes to start them on a new career path. In other cases, people could be transferred to a different department, in the same company. Of course, a small number of employees can become system supervisors and maintenance workers in the same department.

Change is indeed scary, but when we consider both pros and cons, we can start to see that it’s also needed. We can’t continue to lose human lives to jobs that can easily be performed by a smart machine!

Art Gueli

Arthur Gueli is a founder of InjuryClaimCoach — a website dedicated to helping personal injury victims get answers.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.