A hybrid computer vision and artificial intelligence/deep learning approach will improve factory throughput and quality.

By David Kuo, Sr. Director Business Development and Product Marketing at Mythic

Over the past few decades, factories have become more and more automated, bringing efficiency to new heights and driving down the costs of the goods that consumers use every day. Manufacturers have already implemented or are considering the idea of implementing computer vision (CV) in their manufacturing processes. CV is a part of a complex approach to smart manufacturing that allows computers and machines to ‘see’ the physical world by enabling them to extract, process, and analyze information from visual inputs. While CV plays a big role in increasing production volumes, allowing factories to produce things faster, more efficiently and more cost-effectively, manufacturers are now taking advantage of new edge-AI processing techniques to combine the power of CV with AI, especially deep learning (DL).

AI and DL leverage computers and machines to mimic the problem-solving and decision-making capabilities of the human mind, enabling systems to detect objects and make predictions with incredible accuracy and speed. Deployed with traditional CV, AI/DL can accelerate anomaly detection for a food processing factory – for example, inspecting cereal boxes for defects on the production line – to improve manufacturing efficiency and lower production cost.

Another example of how AI/DL and CV can be used in the factory is with AI-powered collaborative robots, or cobots, that are designed to work side-by-side with humans. The cobots combine the precision and efficiency of machines with skills and intelligence of human operators to offer the best of both worlds. AI/DL-enabled cobots increase productivity by performing repetitive and strenuous tasks, but also track the human operator’s position to maintain a safe operating environment.

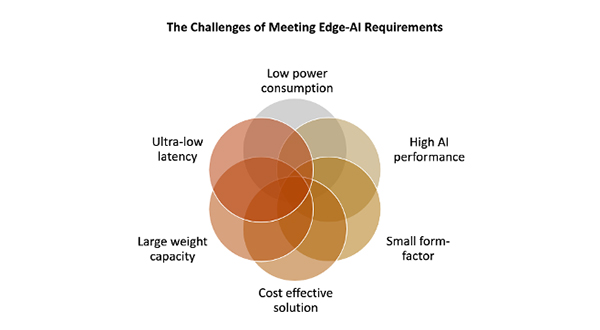

Advancements in edge-AI processing have paved the way for today’s AI robots and will open up new possibilities for robots in the future. Intelligent robots will have to process an incredible amount of information and decisions will need to be made in real-time, so it is much more efficient for these machines to process information at the edge instead of sending it to the cloud and back. Traditional processors cannot meet the CV and AI/DL compute, performance, and power consumption requirements of future robots.

A new approach – analog compute in-memory – promises to solve these challenges and make it possible to widely deploy powerful AI/DL at the edge. Analog compute-in-memory takes advantage of high-density flash memory to enable low latency, compact, single chip AI acceleration for embedded system designs. Equally important, analog compute-in-memory dramatically reduces power consumption for AI processing at the edge, making it 10X more efficient than digital systems while still enabling extremely high performance computing.

As the need for automation in factories continues to grow, the introduction of AI and deep learning will improve the accuracy and efficiency of day-to-day processes. This opens the door to introduce even more “smart” applications into today’s factories, from cobots to autonomous delivery drones to self-driving forklifts and beyond. By implementing CV and AI systems to work together, rather than replace one another, the possibilities for the next phase of industrial automation are endless!

David Kuo is senior director of business development and product marketing at Mythic. David has more than a decade of industry experience, managing various projects. He has extensive knowledge of the industrial and consumer IoT, consumer electronics and mobile markets. David holds a bachelor of science in electrical engineering from the University of Nevada, Reno.

For more information on Mythic and its products, visit the website here.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.