Tips to increase productivity and create a great deburring process for sheet metal.

If you work with any type of metal, you will need smart strategies that will not increase the costs of your production and that will increase your productivity. This is especially true when it comes to deburring metal. Each part needs it.

If it’s efficient, it will also maximize motivation and productivity amongst your staff and it will boost your bottom line as well. You will be able to complete client requests quickly and with quality.

Many people working with metal understand that this is important, yet so few have the actual knowledge and technical expertise to implement and create a great deburring process for their business.

However, there are a few very simple tactics that you can use to improve your productivity with deburring metal.

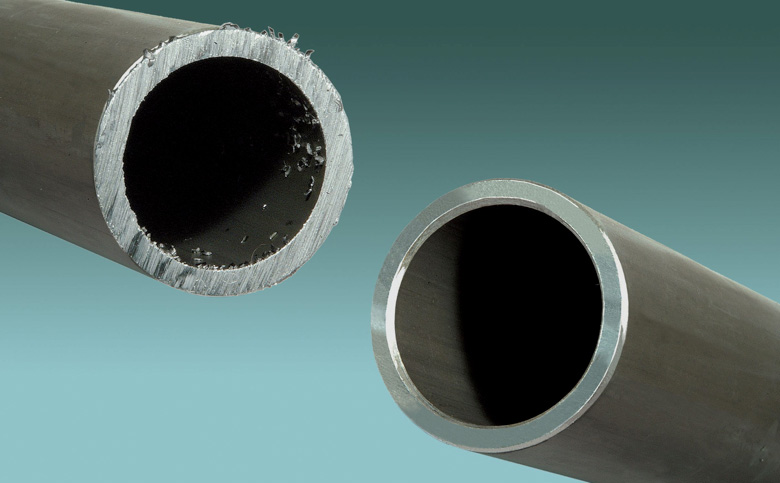

This is a process that means smoothing sharp and rough edges of something made of metal. This includes parts and components. When some piece of metal is drilled or cut, this creates sharp pieces that can harm other materials. This is eliminated through the process of deburring which leaves the lines smooth and clean, unable to snag other materials or even the employees handling them. The purpose here is similar for every tool but people working on metal apply different tools that can range from huge machinery to something handheld like sandpaper for metal. Learn more here.

Now that we’ve covered the basics of deburring, you can understand how to improve the process. Here are a few simple tips:

Automated deburring is the best thing you can do to be more efficient and consistent in your work, as German Company LISSMAC states. These machines create a nice finish and increase the quality of your product.

However, with these fluids, you can cool your machine off, lubricate it and make your deburring operation smoother and safer, not to mention more comfortable for your workers.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.