BSLBATT forklift truck lithium batteries help large american auto parts manufacturer achieve the highest performance for their forklift fleet.

One of our valued customers → A major U.S. auto parts manufacturer faced material handling challenges when its 1.5 million-plus square foot auto parts plant decided to transform from a one-shift operation into a three-shift operation. The plant operates three shifts a day, 240 days a year, with 150 forklifts.

BSLBATT Battery works closely with fleet managers in the auto parts manufacturer’s logistics engineering group to recommend optimized power solutions for industrial equipment. The team’s responsibilities include assessing the plant’s material handling needs and optimizing the correct equipment selection and quantity.

No need to change batteries in 24 hour applications, less than 3 hours of charging time per day.

An American auto parts manufacturer approached BSLBATT Battery with a challenging and complex task. In the future, the intralogistics area will be equipped with a 3-shift operation without the need to change batteries, using traditional lead-acid battery technology.

The lead batteries used in the factory are ideal for powering elevator equipment when a single shift is running; when the shift ends, there is enough time to recharge the lead batteries before the next shift. As new and emerging challenges such as time crunch, unpredictable order peaks or increasing cost pressures are changing truck manufacturers’ demands for modern intralogistics, power and charging efficiency are important considerations.

Previously, forklifts would drive to a charging station a few hundred meters away to replace the battery. This creates serious problems and challenges for the day-to-day operations of intralogistics.

In addition to less use of forklift trucks in production areas, problems such as frequent battery tray damage due to improper battery replacement, poor outdoor road conditions, and humidification of work area floors during inclement weather which are proven to be the most serious problems. Forklifts and energy systems must always be available, reliable and flexible.

These problems will be solved by the relocation of flexible, decentralised charging stations directly into the production area with small battery charging units close to the forklift working area.

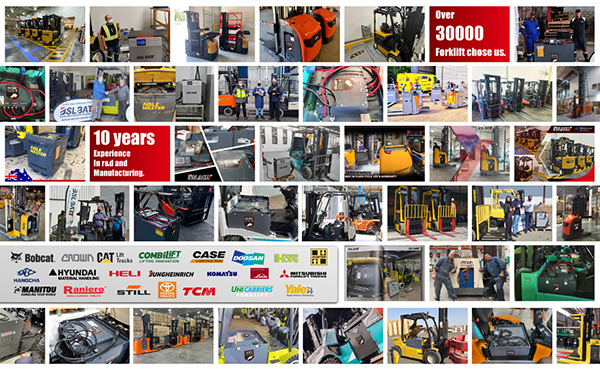

Once lithium was identified as the preferred battery technology, the team conducted a risk analysis of lithium suppliers and their products. Forklift dealers serving the region recommend BSLBATT US Lithium Batteries as the preferred solution.

Lithium Battery for Forklift Truck| The way of the future is at BSLBATT!

First, safety is paramount. The plant’s logistics engineering team determined that the lithium iron phosphate technology used by the BSLBATT Battery is significantly safer than other lithium battery technologies as nickel manganese cobalt (“NMC”).

In response to these needs, BSLBATT Battery recommends its flexible fast charging system BSLBATT charger to auto parts manufacturers, which can be precisely adapted to the needs of the operation process, thus making the work more flexible. BSLBATT fast chargers are distributed throughout the production area, so that the forklift can be used at any time, directly at the point of use. Thanks to a special charging technology that ensures a continuous energy supply for 24 hours, it is possible to significantly increase productivity by saving time and costs.

What makes BSLBATT a premium lithium battery for auto parts manufacturers? The answer is quality at every step. The BSLBATT Battery has been validated to over 60 industry quality and safety checks. It has multiple layers of monitoring, safety, and backup redundancies both in module and complete unit. The battery is designed and assembled in China., and its assembly facilities meet the stringent ISO 9001:2015 certification standards. In addition, BSLBATT is the first forklift lithium battery in China to obtain UL2580 certification for its complete production line. Maximum and safe transfer of energy is conducted through flexible copper busbar cabling. This UL rating is extremely important to logistics engineering teams.

After completing a full deployment analysis to determine the exact energy requirements, BSLBATT Battery showed that only one battery in the forklift can complete the entire deployment. However, it is possibly because BSLBATT Battery, as a absolute solution provider, is able to offer a tailor-made energy system that includes BSL lithium batteries optimized for forklifts, state-of-the-art high-frequency charging technology and smart Battery Cloud System. Can monitor battery voltage, temperature and battery state of charge while charging and control the charger accordingly. This makes it possible to charge the lithium battery to 95% of its capacity in just 1.5 hours.

The BSLBATT Lithium lift truck battery enables fast charging, provides longer runtime, higher/consistent strong voltage across each shift, and efficiently absorbs the regenerative energy of a Class II truck. As a result, the auto parts factory reduced its forklift fleet from 150 to 130. The excess equipment was moved to other facilities of the auto parts manufacturer, saving additional costs for the entire business.

Fleet managers see the deployment of BSLBATT Battery as a model for their other manufacturing and distribution facilities, and share many “learned lessons” with colleagues in the company’s sprawling materials handling department.

3 | Products:

Batteries: B-LFP48-615

Chargers: BSP48V 200A

BSLBATT GPRS Cloud System

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.