Fluke Reliability survey finds 61% of manufacturers predicting to achieve AI goals in just 11 months.

Everett, Wash.: Artificial Intelligence (AI) implementation is expected to play a crucial role in manufacturing operations in the next wave of industrial revolution, also known as Industry 5.0. A newly released report by Fluke Reliability, which empowers reliability and maintenance teams with the hardware, software, and services to optimize asset performance, confirms these claims.

Censuswide conducted the research, which surveyed over 600 senior decision-makers and maintenance professionals in the U.S., the UK, and Germany. The findings confirm that manufacturers are at the forefront of implementing AI technologies into day-to-day operations.

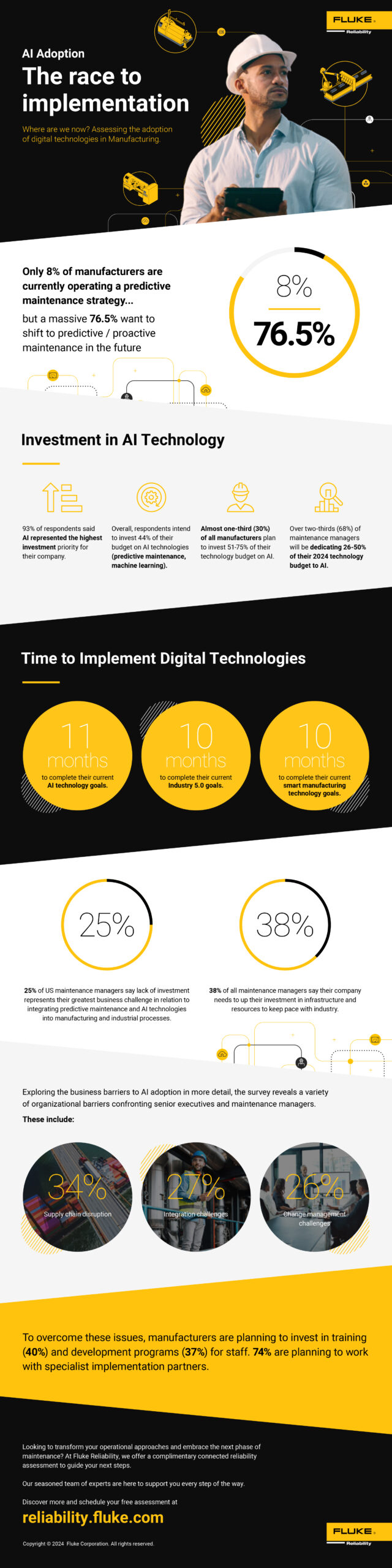

The results offer a clear, almost unanimous picture of the manufacturing landscape. AI will be a high business priority for companies over the next 12 months according to 93% of survey respondents. This sentiment is echoed at an organizational level, with 9 in 10 senior decision makers agreeing AI is the priority and over 4 in 5 maintenance managers saying the same.

Regarding the role of AI in predictive maintenance, only 8% of those surveyed are currently operating a predictive maintenance strategy. However, a massive 76.5% want to shift to predictive/proactive maintenance in the future, and AI implementation is viewed as a tool to achieve that goal.

Manufacturers are already turning their intentions into action, on average respondents said they intend to invest 44% of their technology budgets on AI in 2024 alone. In fact, (30%) of those surveyed plan to invest 51-75% of their technology budget on AI this year.

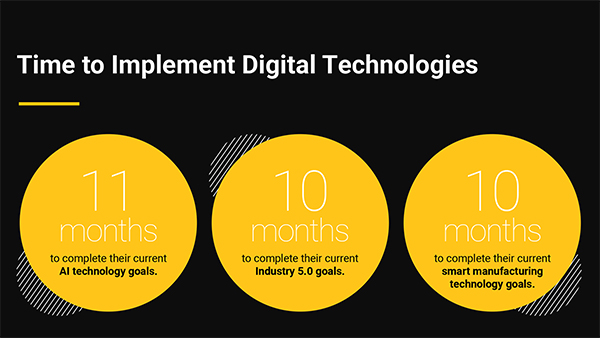

While only 9% of manufacturers agree that they have completed their Industry 5.0 goals to date, the majority (61%) expect to achieve their AI goals in just 11 months.

“Predictive maintenance is becoming a need, not a want, especially as skilled labor is hard to come by and retain,” says Ankush Malhotra, president, Fluke Reliability. “AI offers a clear pathway and there is a strong belief within the industry that manufacturers who don’t adapt to the benefits are likely to be left behind. The results of this survey show that while many industries are talking about AI implementation, manufacturers are walking the talk.”

Of those looking to invest in the next 12 months, the need for adoption was largely driven by the benefits of AI implementation including:

the ability to develop new products and services (35%)

provide a new way to address data processing and analysis requirements (35%)

a means to address the call for improvements to customer service (35%)

the demand for improved efficiency and productivity (34%)

ways to compensate for the skilled labor shortage (31%).

“It’s no surprise that manufacturers are bullish in their adoption of AI,” said Aaron Merkin, chief technology officer, Fluke Reliability. “We know it works and have customers who have seen value in as little as three months.”

To view the full results of the survey, visit Fluke Reliability.

About Fluke Reliability

Fluke Reliability, an operating company of the Fluke Corporation, offers reliability and maintenance teams the tools, software, AI powered insights, and services they need to optimize asset performance. Home to powerful, iconic brands – PRUFTECHNIK, Azima DLI, and eMaint – Fluke Reliability enables customers to shift from reactive to predictive maintenance utilizing a connected approach to reliability. Fluke Reliability informs customers on the health of their assets with software and services that drive better maintenance decisions – improving productivity, driving uptime, boosting visibility, and reducing costs. For more information on Fluke Reliability’s eMaint CMMS, visit https://www.emaint.com/ or LinkedIn.

Fluke Reliability is a registered trademark of Fluke Corporation. The names of actual companies and products mentioned herein may be the trademarks of their respective owners. For more information, visit the Fluke website.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.