The client, a multinational office supply retailing corporation, handles a variety of package sizes and weights, with package contents ranging from lightweight items such as pens and staples to heavier items such as office desks and executive office chairs.

With the increase in online e-commerce orders and demand for same-day shipping caused an increase in bottlenecks, labor costs and order errors. The e-commerce orders packaged needed to include a packing slip with product descriptions, important collateral, like warranty information, manuals, invoices, receipts and coupons. With increasing minimum wages and labor costs, company profits were drifting further and further away affecting the bottom line. During peak order periods, costs per order increased as more labor was needed to fulfill orders. On average, manually printing, scanning, folding and inserting order documentation requires 30 to 45 seconds per customer order. With 28,800 seconds in an eight-hour shift, one employee can manually print, scan, fold and insert order documentation to 640 to 960 cartons, without breaks or overtime. Furthermore, with the increase in labor and orders caused an increase in order errors and delays in shipping.

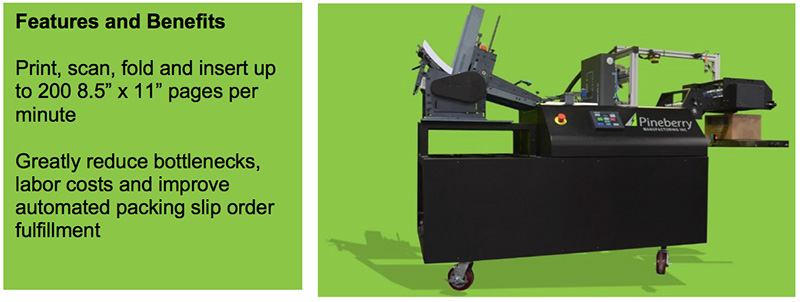

Pineberry Manufacturing Inc. delivered the InstaPrint Packing Slip Inserter. As companies strive to improve their bottom line, especially during peak order periods, integrating a fully automated pack station packing slip line is the quickest and easiest method to package orders that yields the lowest cost per order.

The InstaPrint Packing Slip Inserter prints, scans, folds and inserts up to 200 pages per minute on demand, greatly reducing bottlenecks, labor costs and improving automated order fulfillment. As packaged contents come down the conveyor line to the pack station, the InstaPrint Packing Slip Inserter prints, scans, folds and inserts packing slips, invoices, receipts, warranty information, rebate offers and coupons. It’s a very robust, economical solution. With an inkjet drop-on-demand printer and no printer duty cycle, if a rare jam occurs it can be cleared in seconds, making InstaPrint the most reliable pack station packing slip automated system on the market.

With no consumables other than ink, the InstaPrint Packing Slip Inserter is cost efficient proving a quick ROI. Built with read and print software, packing slips are printed, scanned, folded and inserted into cartons at high speeds on demand with 100% accuracy; there is no need to scan down the line. The InstaPrint Packing Slip Inserter is designed to increase capacity in distribution centers, reduce the number of packing stations, reduce bottlenecks and labor costs, and improve the overall order fulfillment process.

Integrating the InstaPrint Packing Slip Inserter decreased excess labor costs, order errors and bottlenecks, especially during peak order periods; efficiently getting orders out on time at less cost. Ultimately, automating the pack station packing slip system, costs per order drastically decreased, proving an attractive ROI.

In today’s demanding e-commerce world, every second counts during the packaging and shipping of orders. New and innovative technology allows for easy installation without having to change documents or warehouse management software. Competitive corporations that integrate an automated packing slip pack station system for their order fulfillment lines reduce the number of pack stations in their distribution centers, increase pack station throughput, and improve profit per order. All compelling reasons to master peak order fulfillment.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.