Contract manufacturing services for FIPG/FIPFG foam gaskets and application-specific polyurethane seals at Injection Molding & Design Expo 2.

Wixom, MI, USA. Fast, precise, high-quality – RAMPF Group, Inc. is present- ing its contract manufacturing services for FIPG/FIPFG foam gaskets and application-specific polyurethane seals at Injection Molding & Design Expo 2023 from September 20 to 21 in Novi, MI – Booth 1203.

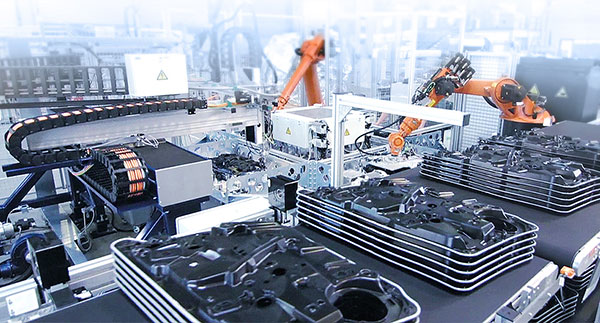

The automated mixing and dispensing of gaskets guarantees both for efficient production processes and the long-term protection of components against moisture, dust, chemicals, and various environmental influences.

RAMPF Group, Inc. offers its customers premium contract manufacturing services using top of the range mixing and dispensing machinery together with holistic automation solutions. Customers use this offer to outsource their manufacturing due to intermittent production schedules or who do not have the volume to warrant equipment purchase. RAMPF also supports large-volume contract manufacturing programs in either a customer’s facility or one of its own.

RAMPF processes multi-component reactive polyurethane and silicone foams into gaskets using multi-axis robots. After curing, a seamless gasket (formed in place foam gasket, FIPFG) is bonded to the component and provides static protection against dust and moisture. The foams can also be dispensed into a carrier mold and processed further as a custom-fit, cured gasket (molded foam).

The benefits:

> Maximum productivity thanks to customer-specific system design

> Consistent material quality thanks to regulated air load

With dispensing technology and robot-assisted automation solutions, polyure- thane and silicone sealing beads are applied to a wide variety of components. After curing, a non-detachable, elastic gasket (formed in place gasket, FIPG) is bonded to the component and provides static protection against dust and mois- ture. Flexible production systems with surface activation for improving adhesion, heat treatment, and quality monitoring ensure optimum production results.

The benefits:

> Consistent material quality via dynamic or static mixing processes

> Precise overlapping points thanks to displacement-free shut-off technology

> Integrated systems for improving adhesion, rapid curing, and leakage testing

RAMPF is leading specialist for both mixing and dispensing technology and sealing sytems based on polyurethane and silicone. Gordon Winter, Operations Manager at RAMPF Group, Inc. – “We combine our engineering, application technology, automation processing, and material know-how to find the best solution for the specific requirements of our customers. And we achieve this in minimum time with maxi- mum efficiency.”

Visit RAMPF at Injection Molding & Design Expo 2023 from September 20 to 21 in Novi, MI – Booth 1203!

RAMPF Group, Inc., based in Wixom, Michigan, USA, is a market-leading specialist for

> Mixing & dispensing systems for the reliable processing of polymers

> Two-component polymer systems based on polyurethane, epoxy, and silicone

> Modeling and mold engineering materials, in particular for the automotive, marine, and aviation industries

> Machine bases, machine frames, and other structural components made from mineral casting (polymer concrete)

RAMPF Group, Inc., is a company of the international RAMPF Group based in Grafenberg, Germany.

Published by:

RAMPF Group, Inc.

49037 Wixom Tech Drive

Wixom, Michigan 48393, USA

T +1.248.295-0223

F +1.248.295-0224

E info@rampf-group.com

www.rampf-group.com

Your contact for images and further information:

Benjamin Schicker

RAMPF Holding GmbH & Co. KG

Albstrasse 37

72661 Grafenberg, Germany

T + 49.7123.9342-1045

F + 49.7123.9342-2045

E benjamin.schicker@rampf-group.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.