Volume 27 | Issue 4

Click here to read the complete illustrated article or continue below to read the text article.

By David Soyka, Senior Editor, Industry Today

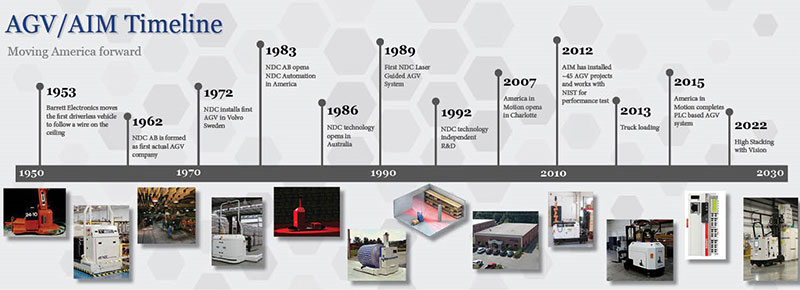

The notion of automated artificial servants actually date back to antiquity, with the first primitive industrial robots appearing in the 1930s. While he might joke otherwise, Tommy Hessler, CEO of America in Motion, hasn’t been involved with robotics quite that long, but his history as an innovator in mobile automation does date back to the 1980s.

“Back then it was more of a marketing tool,” Hessler says. “It was a novelty for companies that wanted to show off how modern they were at red carpet presentations on how robots might work, but there were actually few real business cases. They might have had a few machines on the floor, though, and eventually discovered they actually could do something.”

Not only could they do something, they had a significant bottom line impact. “Back in 1990s, before the Internet, newspaper printers had these huge paper rolls that weighed 1500 pounds. Four to five hundred of these paper rolls were moved on forklifts at a total handling cost of about $1,000 per roll,” Hessler says. “We put together an automated system to move those rolls and reduced material handling costs by as much as 10 percent. Even if you only lowered costs by 3%, that’s still roughly a $35,000 savings.”

Of course, an automated forklift back then was primitive by today’s standards; since then, robotic technology has evolved from science fictional speculation to everyday reality. Following his work in several previous automation and robotics companies, Hessler founded America in Motion in 2007, the same year as the introduction of the iPhone. And, like the iPhone, the technology has undergone exponential advancements.

“The first early mobile robots followed a wire track on the warehouse floor,” Hessler explains, “This was a limited, cumbersome application that required cutting up the floor to lay the wire. So you couldn’t change anything once the wire was in.”

The next development was a free ranging robot that was not physically bound to the floor. Instead, the robot used a laser scan to locate reflective targets to travel to, a much more flexible approach. Today, we have eleven different ways for a mobile vehicle to navigate through a set of programmable coordinates.”

Unlike most of its competition, America in Motion is more than just a hardware provider of automated forklifts. Rather, the company is a provider of custom but open-source guided vehicle solutions comprised of:

Applications include high-volume material handling, repetitive transport tasks, hazardous and other high-risk transport, limited labor availability, and accident reduction. In addition, an AGV solution can be integrated with other existing automation, such as conveyer systems and robotic arms. “Unlike some of our competitors, we don’t believe in proprietary systems,” Hessler emphasizes. “Some companies like to keep you in their own ecosystem because that benefits them. We’re looking to benefit the customer.”

The many benefits of AGV solutions are compelling:

While some customers do just order the AGVs, Hessler emphasizes that more benefits are realized employing a more holistic systems solution.

“For a lot of customers, the mindset is still like buying a microwave, they think of it as just another piece of hardware. You get it, you plug it in, and it does a specific job,” he says. “The analogy I make is that what you are really buying is a kind of fighter jet that has a lot of sophisticated interlocking parts and requires specialized skills to operate. And there’s a lot more you can do with fighter jet kind of product than a microwave.”

Many of those benefits are quickly illustrated with a virtual session. “This is where customers try out various layouts and solutions and really see the value they can attain,” Hessler says.

“We don’t believe in a cookie cutter approach,” he adds. “We work with customers to learn about their workflows, develop several iterations of functional specs to ensure we’ve got everything right, then build the system at our 20,000 square foot facility in Charlotte, North Carolina, and finally install it and train the customer in its operation. Ideally, we continue the relationship to collect data to further refine and optimize the system.”

America in Motion has only 25 employees, though it partners with other companies preferably local to the customer whenever possible. The typical lead time from consultation to installation typically takes about six months. True it its name, customers are primarily in the U.S., Canada, and Mexico, though it does have international customers as well.

Hessler originally came up with the America in Motion name to symbolize how AGVs can revitalize manufacturing while at the same time facilitating employee job security and satisfaction. “I saw automation as a way for American manufacturers to improve efficiencies and become more competitive with offshore low-cost labor,” Hessler says. “And the intent of automation is not to replace employees, but to relieve them of repetitive and sometimes dangerous tasks and retrain them for more rewarding careers. You need people to program the robots, manage them and maintain them. That’s why while Japan has the highest level of automation, it also has the highest levels of job retention.”

This integration of people and robots extends to the point where workers like to name AGVs. “We found that people interact better with a robot they give a name.” Hessler says. “By personifying the robot as ‘Bob’ as opposed to just ‘the robot’, people feel more comfortable working with it.”

Artificial intelligence is the next breakthrough in AGVs. “With AI capabilities, not only can the robots learn and adapt to new situations, they can also move in unfamiliar spaces,” Hessler says. “Right now, an AGV can’t go into a truck to unload materials, because its reference points are solely within the facility. With AI, the AGV can recognize that it is a new environment, orient itself, and then perform its task.”

America in Motion experienced a boost in sales during the pandemic, not surprisingly given concerns about hygiene and safer working conditions. However, Hessler says that this peak demand reflected short-term thinking.

“It goes back to are you buying a microwave or a fighter jet. What’s the point of buying a jet if you’re only using it to make popcorn,” he says. “Too often companies are focused on what’s going to happen five years from now, or even sooner, compared to companies in Japan that are focused on the next fifty years. Our AGV solutions are future-proof. Typically, you see an ROI in two years. But that’s just the start. You can continually build on an AGV solution to gain more efficiencies and free-up more time for important high value activities, further grow your business, stay competitive, and all the while engage your people in safer, more rewarding tasks.”

He adds, “AGVs aren’t just a trend, they are a core strategy for a more efficient, safer, and cost-effective workplace. We’ve been building AGVs for 17 years, and the future has never looked more promising to integrate AGV solutions to optimize workflows and improve working conditions. An investment in an AGV solutions isn’t just as investment in some hardware and software, it is an investment in a company’s future.”

In 2007, Tommy Hessler was appointed President and CEO of America in Motion. With extensive experience in the industry, he recognized a critical need for customizable AGV mobile robotics solutions. Tommy envisioned a customized mobile automation approach that meets the unique needs of each customer rather than the traditional cookie-cutter approach. Originally from Sweden, Tommy has dedicated his entire career to the mobile robotics and AGV sectors. He spent several years at NDC Technology in Australia before taking ownership, further solidifying his expertise and commitment to innovation in this field.

This article is sponsored by America in Motion.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.