Company creates innovative micro-3D printed medical device to accurately record the neuronal activity in mice.

Waltham, Mass. (GLOBE NEWSWIRE) — Nano Dimension Ltd. (Nasdaq: NNDM) (“Nano Dimension”, “Nano”, or the “Company”), a leading supplier of Additively Manufactured Electronics (“AME”) and multi-dimensional polymer, metal & ceramic Additive Manufacturing (“AM”) 3D printing solutions, today announced that it has partnered with leading research centers in Canada and France on a breakthrough project using its precise Fabrica micro-3D printing systems. The study centers around the accurate recording of neuronal activity in mice, with the aim to elucidate the neuronal circuits and mechanisms involved in the processing of somatosensory information. The results of the project underscore the vital role played by innovative manufacturing solutions in the advancement of biomedical research and the development of cutting-edge medical devices.

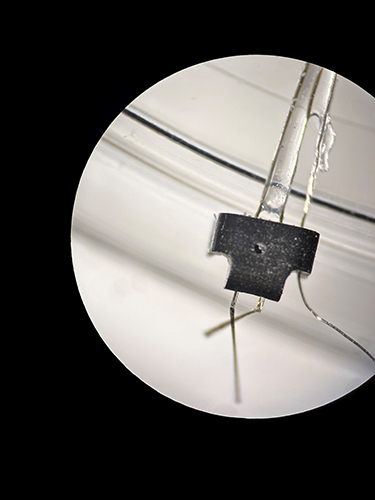

According to the research team, which comprised researchers from three leading institutions, small or micro medical devices for research project purposes pose significant challenges in production due to their size, dimensional requirements, and intricate features. In this instance, the team needed to design a miniature brace capable of securely holding two electrodes on the vertebra of the mouse. To date, limited attempts have been made to explore the electrical activity of dorsal horn neurons in awake animals, which presented its own challenges for the team.

“Recording the electrical activity of neurons in the spinal cord of a conscious animal is not easy, mainly due to the movements induced by walking and breathing of the mouse, as well as the accessibility of the area in question,” explains Louison Brochoire, a PhD student at the University of Bordeaux in France.

“For this project, we needed the brace to allow movement of the animal while firmly securing and stabilizing electrodes that were inserted into very minute holes,” adds Brochoire, who worked under the supervision of professors from Bordeaux’ Institut des Maladies Neurodégénératives, as well as from the CERVO Research Center and University of Laval in Québec, Canada.

Mindful that traditional manufacturing methods would involve a lengthy struggle to produce a device that could effectively stabilize electrodes in place while maintaining accuracy and functionality, the team partnered with Nano Dimension to find an alternative solution.

The intricacy of the design challenge required precise dimensions, including 110µm holes for electrodes in a part that was merely 2.7mm in width. This saw Nano Dimension deploy its Fabrica micro-3D printing technology, which provides unparalleled micron-level precision. Using its Fabrica 3D printers, which produce accurate and functional parts with tight tolerances and a pixel size as small as 4µm and a layer height of between 1-10µm, the company was able to successfully 3D print the required brace. This provided a functional part for the team to use in their research within just one week.

For the research team, the result met their requirements exactly. “The ability to create such precise and minute holes within the brace was critical,” says Brochoire. “This design attribute helped to minimize artifacts caused by breathing and movements of the animal, which would interfere with our electrical signal, complicating the analysis of results.”

To deliver a functional part that met the specific requirements for implantation into a mouse, Nano Dimension used its bio-compatible Fabrica Medical M-810 material. With its clearance for cytotoxicity, which ensures that it is not toxic to human cells, the material was the perfect fit for the device needed by the team.

“The high precision and resolution of Nano Dimension’s micro-3D printing technology, coupled with the use of biocompatible material, empowered us to create a new tool essential for achieving our primary objective. The alternative using other means would have involved printing and modifying a larger part to achieve the desired features. This could have taken several months, which for a research project would be a real issue. Clearly, the use of such technologies in the medical field will surpass many limitations,” Brochoire concludes.

As well as Louison Brochoire, the other members of the research team comprised Professor Pascal Fossat from the Institut des Maladies Neurodégénératives (IMN); Professor Yves De Koninck from Québec’s CERVO Research Center; Professor Benoit Gosselin from Québec’s University Laval, Faculty of Science and Engineering, Department of Electrical and Computer Engineering; and Juliette Viellard, Post Doctoral Researcher from the University of Bordeaux

About Nano Dimension

Nano Dimension’s (Nasdaq: NNDM) vision is to transform existing electronics and mechanical manufacturing into Industry 4.0 environmentally friendly & economically efficient precision additive electronics and manufacturing – by delivering solutions that convert digital designs to electronic or mechanical devices – on demand, anytime, anywhere.

Nano Dimension’s strategy is driven by the application of deep learning based AI to drive improvements in manufacturing capabilities by using self-learning & self-improving systems, along with the management of a distributed manufacturing network via the cloud.

Nano Dimension has served over 2,000 customers across vertical target markets such as aerospace & defense, advanced automotive, high-tech industrial, specialty medical technology, R&D and academia. The company designs and makes Additive Electronics and Additive Manufacturing 3D printing machines and consumable materials. Additive Electronics are manufacturing machines that enable the design and development of High-Performance-Electronic-Devices (Hi-PED®s). Additive Manufacturing includes manufacturing solutions for production of metal, ceramic, and specialty polymers based applications – from millimeters to several centimeters in size with micron precision.

Through the integration of its portfolio of products, Nano Dimension is offering the advantages of rapid prototyping, high-mix-low-volume production, IP security, minimal environmental footprint, and design-for-manufacturing capabilities, which is all unleashed with the limitless possibilities of additive manufacturing.

For more information, please visit www.nano-di.com.

NANO DIMENSION MARKETING CONTACT

Normann Fichtner, Market Development Director, AM | Normann.Fichtner@nano-di.com

INCUS MEDIA RELATIONS FOR NANO DIMENSION +44 1737 215 200 | nd@incus-media.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.