Propelling aerospace and defense to new heights with high performance magnet motors.

By David Farnia, Director of R&D, Arnold Magnetic Technologies, and Aaron Williams, VP of Sales and Marketing, Arnold Magnetic Technologies

High-performance permanent magnet motors are propelling major technological progress in the aerospace and defense sectors. Innovations in material science, electrical engineering, mechanical engineering, and advanced manufacturing have contributed to the development of state-of-the-art permanent magnet motors and generators that support applications that demand the highest levels of power density, reliability, and longevity.

These mission-critical applications include propulsion and power generation systems in military aircraft, surface ships, submarines, drones, portable munitions, and armored vehicles. Furthermore, these technologies have extensive applications in satellites and the electrification of commercial aviation, facilitating remarkable advancements such as electric vertical takeoff and landing (eVTOL).

The origins of permanent magnet motors can be traced back to 1821 when British scientist Michael Faraday succeeded in producing mechanical motion with a permanent magnet and an electric current. His pioneering work laid the foundation for the development of the first electric induction motors, which would eventually become ubiquitous. It wasn’t until the late 20th century that the industry experienced a revolution with advancements in high-performance rare-earth magnets, leading to the widespread adoption of permanent magnet motors.

Permanent magnet motors have increasingly become the motor of choice in various applications that benefit from superior energy efficiency and power-to-weight ratio, such as automobile drive systems, power tools, household appliances, and HVAC systems. The efficiency of these motors is especially advantageous to battery-powered systems, extending the range of vehicles and the runtime of power tools.

Automakers have embraced these motors in their EV powertrains due to their impressive power density, efficiency, and compact size. Power tools also benefit from permanent magnet motors, as they offer an ideal combination of high power and portability. Furthermore, their brushless design enhances reliability and longevity compared to traditional induction motor designs.

Efficiency is also crucial for green and profitable power generation, which functions in the opposite manner of electric motors. The higher electrical output of permanent magnet generators translates to increased capacity and a quicker return on investment, while also reducing operating costs of fossil fuel systems. In wind turbines, permanent magnet generators eliminate the need for gearboxes, resulting in significantly more efficient operation. The resulting compactness and high reliability are particularly important, considering the turbines are situated atop tall towers that are challenging to access and maintain.

The exceptional power density and efficiency of these various applications have far-reaching benefits. However, it is in the aerospace and defense sectors where the investment in the latest permanent magnet motor technology is yielding the most dramatic results, pushing efficiencies into the high-ninety-percent range, and achieving remarkable improvements in the all-important optimization of size, weight, and power (SWAP).

The power-to-weight ratio of these motors makes them ideal for aircraft propulsion systems, including rotating and thrust components such as impellers and fans. They are even being used to power satellite components, allowing the craft to precisely maneuver with minimal energy consumption.

Advanced magnetic materials and subsystems developed to meet the extreme temperatures, pressures, and mechanical shock of down-hole oil & gas applications have also proven to stand up well in demanding aerospace and defense applications.

Achieving the high performance required by the aerospace and defense sectors has been a multifaceted R&D challenge, requiring innovations in material science, motor design, advanced manufacturing, and other fields. Let’s look at some of the key attributes of the highest-performing permanent magnet motor and generator systems.

When considering magnet materials for high-performance permanent motor applications, both Neodymium Iron Boron (NdFeB) and Samarium Cobalt (SmCo) are widely used due to their high magnetic strength. However, they differ in several key aspects that can influence their suitability for various applications.

NdFeB magnets exhibit higher magnetic flux density compared to SmCo magnets, which means they can deliver more magnetic pull force. This makes NdFeB magnets suitable for applications that require higher torque output with lighter weight, such as electric vehicles or wind turbines. However, NdFeB magnets have a lower resistance to high temperatures and are more prone to corrosion, which may require additional thermal management or protective coating in certain applications.

On the other hand, SmCo magnets offer superior temperature stability and corrosion resistance. For example, Arnold Magnetic Technologies’ RECOMA 35E SmCo magnet materials, the most power-dense samarium cobalt magnet available, are engineered for the most demanding environments, including high speed (100,000 RPM+), high temperature (150°C-250C), and highly corrosive environments.

Unlike neodymium (Nd) magnets, which need high levels of rare dysprosium (Dy) to function at moderate temperatures, SmCo magnets use materials that are more widely available and are inherently stable at temperatures well above the Curie point of NdFeB. This makes SmCo pricing more stable and less prone to market changes.

Arnold has established domestic supply chains for rare earth materials to ensure full compliance with all US Department of Defense requirements.

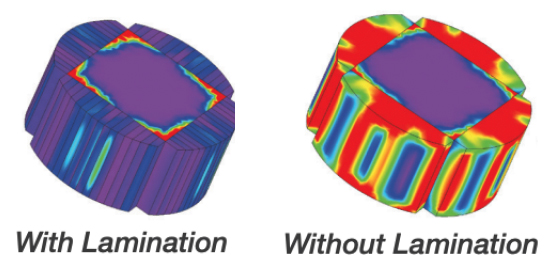

Reducing eddy current losses in permanent magnet motors is essential for achieving optimal performance. Eddy currents are circulating currents induced within conductors by a changing magnetic field in the conductor. They can cause significant energy losses, overheating, and even damage to the motor. In the context of permanent magnet motors, these losses become particularly concerning due to the high frequencies at which these motors operate.

Thinner laminations composed of high-quality materials in the stator and rotor stacks are crucial for the power density and efficiency of high-speed motor applications to reduce core losses caused by eddy currents. Designers seek to balance the tradeoff between power and heat. This technology has always been used in the laminated steel for motors but more recently Arnold has T developed L Type thin laminated rare earth magnets with insulated layers of less than 20 µm and magnetic layers from 0.5 mm and up in custom shapes and sizes in neodymium iron boron and samarium cobalt. This brings traditional electric steel lamination benefits to the magnets themselves.

Another important design consideration is the sleeve which holds the rotor magnets in place. The fundamental purpose of the rotor sleeve is mechanical — securely containing the magnets at high speeds.

However, the sleeve’s location positions it in the flux path between the rotor and stator. If the sleeve is conductive, it will generate joule losses. By employing a non-conductive material like Arnold’s Wraptite carbon fiber sleeving, this cause of joule losses can be eliminated.

Carbon fiber is not only less dense than steel, which improves balance and rotor dynamic characteristics, but the low density also provides higher containment capability by reducing self-induced stresses at high RPM. The lightweight carbon fiber material contributes to improved power densities.

Carbon fiber sleeves have additional benefits. The sleeve’s primary purpose is containing the magnets on the rotor, but it is also important to consider the proximity of the sleeve to the inside diameter of the stator. Flux density distortions increase as the sleeve surface moves closer to the stator slots. Higher flux distortions lead to higher eddy current losses.

Using a carbon fiber sleeve means the gap between sleeve surface and the stator surface need only be a function of mechanical tolerance requirements, giving motor designers the flexibility to optimally design motors to minimize eddy current loss and maximize performance.

Combining a Wraptite carbon fiber sleeve along with a L Type laminated magnet will provide the necessary structural performance while reducing rotor losses by as much as 80%.

In conclusion, the strategic positioning of the rotor sleeve has a significant impact on the effectiveness of the magnetic flux path between the rotor and stator. By opting for conductive materials, specifically Arnold’s Wraptite carbon fiber sleeving, we can effectively eliminate joule losses caused by conductive sleeves. The unique properties of carbon fiber, such as less density than steel, contribute to enhanced balance, improved rotor dynamic characteristics, and notably, a reduction in self-induced stresses at high RPMs.

Arnold’s advancements in high performance permanent magnet materials, coupled with innovative motor design, are indeed redefining power density’s upper limits. They are surpassing previous constraints and paving the way for future technological breakthroughs in aerospace and defense.

Tune in for a timely conversation with Susan Spence, MBA, the new Chair of the ISM Manufacturing Business Survey Committee. With decades of global sourcing leadership—from United Technologies to managing $25B in procurement at FedEx—Susan shares insights on the key trends shaping global supply chains and what they mean for the manufacturing outlook.