Meler, HMI-MBS and Universal Robots pool their know-how to offer an adhesive application workshop with the help of a collaborative robot.

The demonstration took place on January 19 at Meler’s Orleans facility.

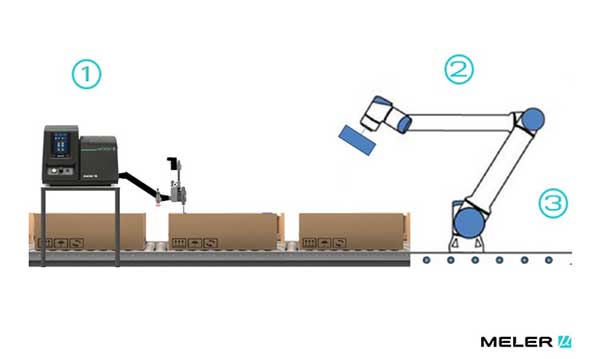

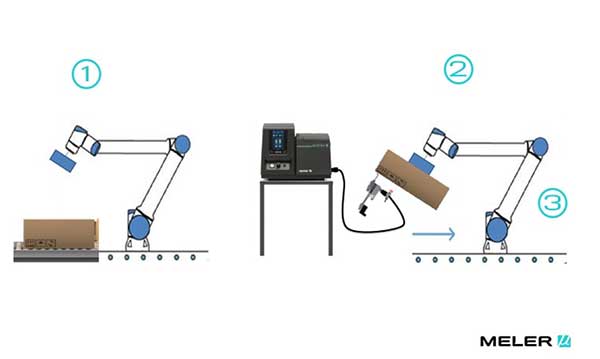

The application of adhesives in every industry is only one stage of the production process in many sectors. It is a part of the whole. That is why Meler France team, in collaboration with HMI-MBS and Universal Robots, has organized a workshop on its premises to show how cobotics could optimized adhesive application at the end of the line.

The day’s programme included a presentation by the organising companies and a real demonstration in which the attendees, with technical profiles from industries such as aeronautics or the automotive industry, were able to see the advantages that a collaborative robot can bring to any adhesive application. Sylvain Pitard, Sales Director of Meler’s French subsidiary, and Julien Plault, HMI-MBS sales technician, explained two real cases of adhesive application in palletizing processes.

The logistics sector has been quick to implement the combination of both technologies: cobotics and adhesive application because of the production benefits they bring to the profitability of the end-of-line. Occupational risks related to loading and transporting goods are reduced (1) and operators can focus on other, higher value-added tasks.

However, the interest in introducing these technologies is not just about cost efficiency and safety. By introducing the application of adhesives, we also eliminate the use of single-use packaging materials (2) and achieve excellent results in the unification of goods. It is this ecological aspect that continues to drive many companies to change their end-of-line installations.

At the end of the demonstration there was a question and answer session in which attendees could receive personalized advice for the implementation of new projects.

In addition to the positive aspects of this type of professional meeting, Sylvain Pitard, Sales Director of Focke Meler France, acknowledges his satisfaction as host: “It is exciting to resume the networking activities that are so typical of a sector like ours, where we always work as a team. It is this type of exchange that makes our commercial activity more valuable and we are also proud to have organized it in our Orléans facilities, which were inaugurated in the middle of the pandemic”.

The objective of this event was the same as that shared by Meler as a company: to improve together the future of industrial adhesive application. . So, this is the first of many more. If you are interested in new sessions, write to marketing@meler.eu.

VIDEO ROBOT https://www.youtube.com/watch?v=_jDHsIrQiI0

More info at:

MARKETING & COMMUNICATION DEPARTMENT

Focke Meler Gluing Solutions

marketing@meler.eu / bmatias@meler.eu

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.