US manufacturers needlessly lose $7.5 billion annually from serious workplace accidents. Here are five proven ways to stop this loss.

When manufacturers improve workplace safety, they significantly strengthen the bottom line, improve quality and help attract and retain skilled employees in a historically tight labor market.

However, not all manufacturers get it. Those who don’t, collectively spend more than $140 million each week on serious, non-fatal workplace accidents, according to the latest Liberty Mutual Workplace Safety Index.

While staggering, that value reflects just the cost of medical and lost-wage payments from the 10 leading causes of the most serious accidents. The true impact grows exponentially given overtime, employee burnout and quality issues resulting from skilled workers being sidelined.

The good news? Manufacturers can follow five best practices to improve workplace safety and start realizing its benefits. And they have unexpected allies in these efforts: their insurance carrier, agent and broker. The value these partners add should go beyond insurance coverage to include the expertise and resources needed to prevent accidents.

As a leading workers compensation insurer, we’ve uncovered five keys for improving workplace safety.

Workplace accidents and injuries are not pre-ordained events that should be tolerated as a normal cost of business.

Effectively improving workplace safety starts with understanding the causes and cost of accidents to address those having the greatest negative impact.

Work with insurance partners to identify what injuries happen and the resulting costs across the company, as well as for specific divisions and locations.

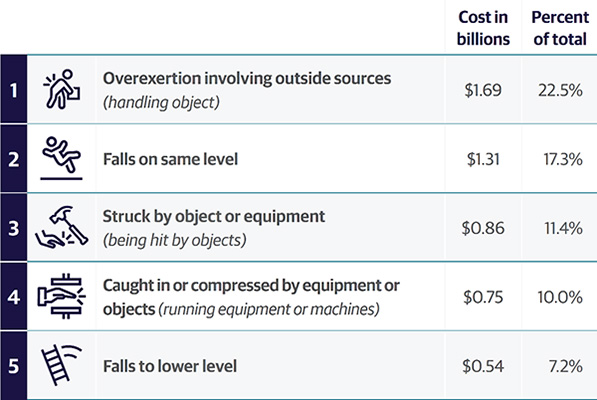

The top five causes of the most expensive non-fatal injuries experienced by manufactures are:

Investigate the causes of the most serious accidents and injuries.

Engage front-line employees in gaining this understanding. They know the best way to work safely, and why they sometimes fail to do so.

Was someone rushing to meet an unrealistic production goal when they got injured? Was the work process poorly designed given the physical capabilities of the average employee? Was someone operating a piece of equipment on which they were not trained?

Involving employees in safety improvement fully engages them in these efforts. It gains buy in and prevents an “us vs. them” mentality, making if far more likely that employees follow work procedures and reporting requirements.

Understanding why accidents happen lets manufacturers identify what can be done to prevent them, and their associated human and financial impact.

Insurance partners should be able to work with a manufacturer to help prevent the most frequent or expensive injuries.

One of these involves lifting, pushing and pulling tasks, such as repetitively lifting a 50-pound box from the floor to a workstation.

Our risk engineers work with policyholders to re-engineer work procedures to address this issue and other causes of workplace injuries. For example, by using a proprietary AI-powered tool, they can analyze videos of a job task and immediately understand the stresses placed on the body, the potential injuries that can occur and ways to reengineer the task so that more workers can perform it safely.

Should assistive devices, such as lift tables, be needed to prevent injuries, our risk engineers can help build the business case for such investments.

Building a “safety culture” takes the active engagement of employees throughout the company.

Senior leaders must take every opportunity to highlight the importance of safety, its role in the company’s profitability and competitiveness, and the expectation that it must never be compromised to meet deadlines or production goals.

Onboarding new employees is the perfect time to begin to build this culture. New hire training must highlight the company’s safety culture and importance, and clearly explain work procedures as well as the consequences of failing to follow them.

Management – from the C-suite to line supervisors – must continually underscore safety’s priority. It is not a hard sell. A safer workplace benefits everyone.

Improving workplace safety is a continuous process. A virtuous cycle.

Good is never good enough. There is always more financial and human pain to prevent.

As safety improvements are implemented, their impact must be monitored and reported, and significant impacts celebrated.

In a world of thin margins, demanding quality standards and tight labor markets, manufacturers stand to gain a host of critical benefits by improving workplace safety. Luckily, they are not alone in these efforts, and should look to their insurance partners for the resources and expertise to better protect employees and the bottom line.

About the Authors:

TJ Richter is Executive Underwriting Officer, Manufacturing/Wholesale, Liberty Mutual Insurance. He manages a team focused on helping mid-size manufacturers better understand, mitigate and manage the complex risks they face through effective insurance programs.

Dorothy Doyle is General Manager, Risk Control, Liberty Mutual Insurance. She leads a team of safety professionals that works with policyholders everyday to improve workplace safety.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.