In the current tumultuous global economy, manufacturers may be developing frown lines from constant worry about challenges that range from growing labor shortages, and shifting customer needs to digitization’s growing impact on production, shipping and customer relationships.

But those organizations which have a dedicated continuous improvement effort in place have less reason to stress, according to a newly published report by Forbes Insights and ASQ — a global community of quality professionals. The study finds that top executives and quality professionals see a direct link between the success of their organizations and continuous improvement and performance excellence initiatives.

The report surveyed 1,869 senior executives and quality professionals around the world, including the U.S. Thirty-six percent of enterprises surveyed said that they regard themselves as an established quality organization while 39 percent reported that they are still developing their quality programs; 25 percent said they are struggling to implement quality in their companies.

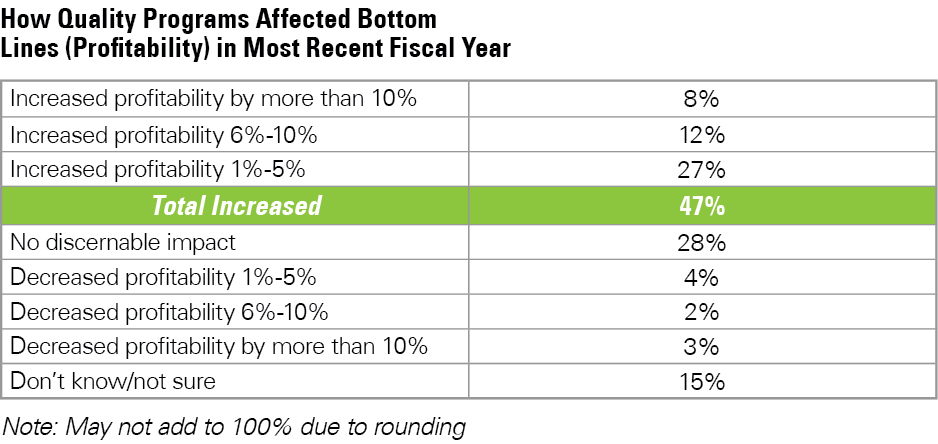

Close to 50 percent of those organizations which embrace quality, say that continuous improvement efforts contributed to profitability growth — with one in five saying quality contributed more than 5 percent — in the most recent fiscal year. Operations, customer service and production are the areas most likely to include quality initiatives and customer growth and sales, followed by efficiency gains seem to be the biggest benefits of these programs.

It’s no secret that the skills gap is a major issue for industry today. Over the next decade nearly 3 ½ million manufacturing jobs will likely need to be filled but the shortage of skilled labor is expected to result in 2 million of those jobs going unfilled, according to the Manufacturing Institute. With a skilled workforce in short supply, more organizations are stepping up and collaborating with partners to develop training programs and curriculum that meet their needs.

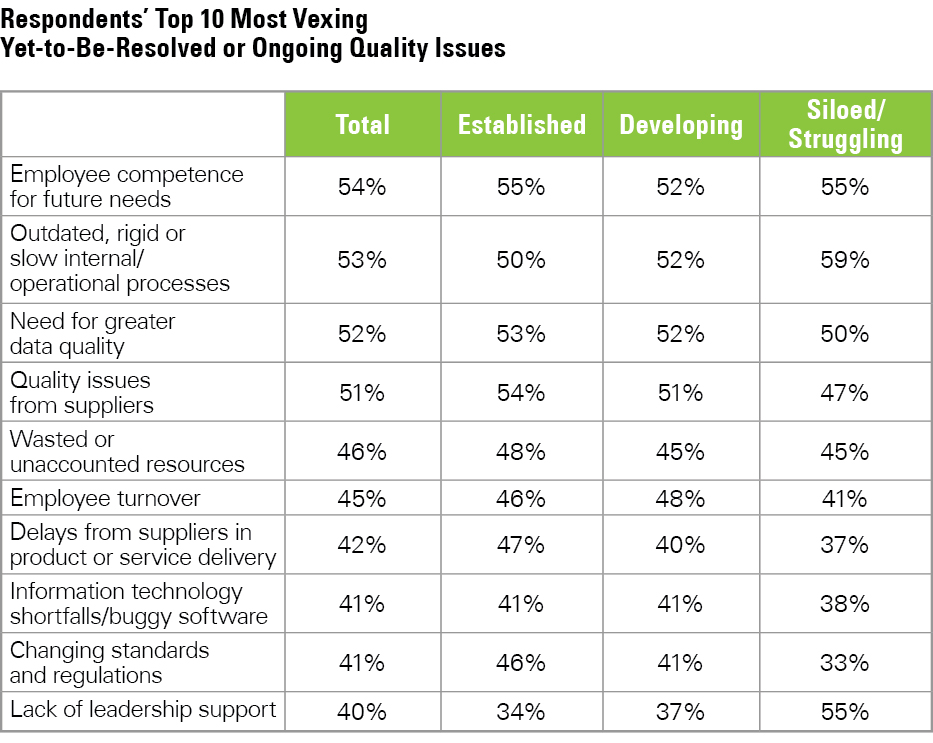

But when it comes to quality initiatives, according to the ASQ report, most senior executives find it an ongoing challenge to provide the appropriate level of training, skills and support to see continuous improvement programs through. Fifty-four percent of corporate leaders cite employee competence for future needs as their most vexing yet-to-be-resolved quality challenge, followed by outdated, rigid or slow processes. That’s followed by dealing with outdated, rigid or slow internal processes (53 percent) and the need for greater data quality (52 percent).

Right now, the majority of all respondents, 75%, measure the impact of their quality programs to some degree but only one in four say this measurement is extensive.

The good news is that a majority of enterprises surveyed in the report, 70%, say that digital processes and the movement to digital enterprises have been transforming their continuous improvement initiatives to some extent. A majority, 52%, state that digital processes are requiring faster responses to issues or changes in product or service delivery. Close to half of respondents said that there are a broad range of other adaptations including availability of more actionable data, a greater focus on services and information quality and more attention to customer experiences.

Manufacturers who are looking to strengthen their quality profile over the coming months and years would be wise to consider the following action steps:

Are your quality tools, models and frameworks prepared to help shape the new Industry 4.0 paradigm?

To download the free Forbes Insights/ASQ report visit www.economicsofquality.org

About the Author

About the Author

Paulo Sampaio is Professor of Quality and Organizational Excellence and Vice-Dean at the School of Engineering, University of Minho, Braga, Portugal. Paulo is also Visiting Scholar at MIT, USA, and a member of ASQ’s Global Advisory Committee.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.