A new age of surveillance, led by AI tools, AR, and VR, is helping manufacturers get a step ahead of potential threats in the workplace.

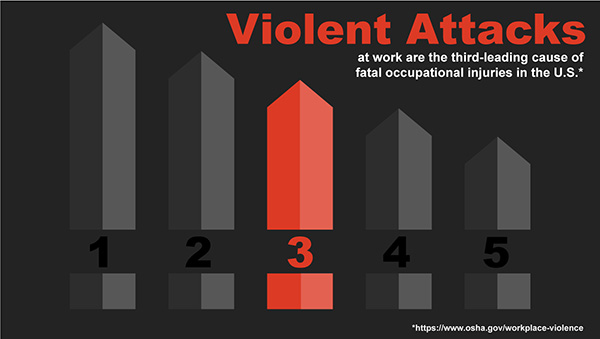

Violence in the workplace is an uncomfortable but undeniable reality across every sector of manufacturing. According to OSHA, violent attacks at work are the third-leading cause of fatal occupational injuries in the U.S. Millions of workers face verbal abuse, intimidation, and physical assaults each year—which undermines safety, productivity, and overall morale on the factory floor.

Thankfully, a new wave of workplace safety technology is giving business leaders more power to stay ahead of threats and other inefficiencies. Manufacturers now have access to advanced tools like AI-powered surveillance, biometric access controls, and enhanced training using AR/VR.

Workplace safety advancements are already paving the way for a new era of operational security that will revolutionize worksites everywhere, and Pinkerton is ready to help companies navigate what can often be an overwhelming process. Let’s take a look into the latest security breakthroughs in our industry, and how pairing advanced technology with talented, well-trained staff can protect your business today while preparing it for tomorrow.

The advent of AI-powered surveillance systems is already revolutionizing the way manufacturers monitor their worksites, even as the technology is still in its infancy. Unlike the security methods of years past, AI-powered cameras are equipped with intelligent, predictive software that can help identify unauthorized personnel, monitor suspicious behaviors, and detect the improper use of equipment—all in real time. Carefully crafted monitoring programs can get ahead of potential threats to identify aggressive sentiments that may escalate to workplace violence.

With new, smart tech in place, security personnel now have an extra set of eyes working alongside them to identify threats. Teams that implement predictive AI-driven security systems and software can receive real-time alerts about potential problems, which gives staff an immediate opportunity to resolve issues.

The necessity for strict access controls to sensitive areas is nothing new in manufacturing. But the methods used to monitor it are evolving—and improving—at a remarkable pace. Fingerprint and facial recognition technology now makes it possible to grant or restrict access based on physical characteristics, instead of a badge or a key code. After all, badges can be faked and key fobs can be duplicated but faces and fingerprints are unique to each individual.

This kind of next-level security is vital to any facility that stores hazardous materials, proprietary technology, or high-value inventory. By using biology-based metrics to restrict facility access, manufacturers are in a stronger position to prevent both inventory theft and unauthorized access to sensitive equipment, materials, or trade secrets.

While AI surveillance and biometric access systems address external threats, manufacturers are also leveraging virtual reality (VR) and augmented reality (AR) to add an extra layer to on-site security training for internal staff.

VR and AR tools can replicate actual facility layouts and site-specific risks, which gives security staff the chance to rehearse high-pressure response procedures in a realistic and controlled environment. This provides entire security teams with simulated experience for scenarios that have yet to occur while preparing them to respond effectively in the event that they do.

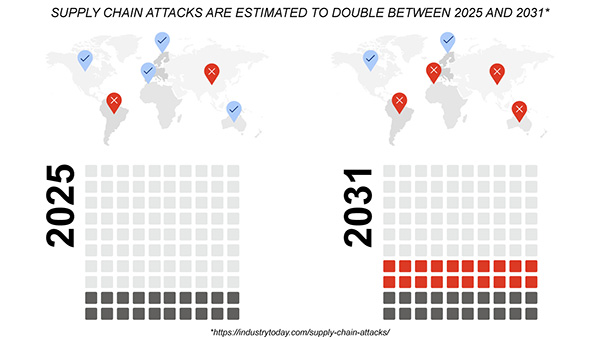

The global supply chain is what keeps manufacturing facilities, and the economy as a whole, running. Unfortunately, supply chain attacks are on the rise—and industry experts expect them to more than double from 2025 to 2031.

AI monitoring and predictive analytics can give manufacturers more timely, accurate information on potential threats to the supply chain. Predictive analytics is an especially useful tool for staying one step ahead of bad actors, as system software can flag potential threats such as unauthorized access or product theft and have the issue automatically forwarded to a trusted security partner, like Pinkerton. So, rather than merely reacting to a supply chain disruption, company leaders can use up-to-the-second info to prevent it from occurring in the first place.

Adding to that, when companies work with Pinkerton to secure their operations, they also receive access to our proprietary crime tracking and prediction software, the Pinkerton Crime Index (PCI). PCI draws from the latest national and regional data, which is then used to determine risk scores based on location, time, and behavioral patterns associated with increased crime. By combining advanced technology, PCI data, and trained staff, businesses that partner with Pinkerton can build a layered, integrated security approach that puts them ahead of both criminals and competitors who haven’t embraced the latest breakthroughs in security.

The threat of workplace violence isn’t going away anytime soon. However, we’ve seen rapid advancements in both security technologies and proactive methods that make it easier to prevent and respond to these risks effectively. When used together, the latest technology and trusted security expertise become more powerful than just the sum of their parts. It develops a layered security strategy that has the depth and staying power needed to keep worksites safe.

As we start 2025, manufacturers everywhere are working to keep their operations a step ahead of bad actors and other business disruptions. The best-protected companies will be the ones that are unafraid to adopt the new technologies and training methods that will serve as the foundation for long-term solutions to operational security.

About the Author:

Denise Castellot is a Director at Pinkerton, where she uses her extensive risk analysis and consulting background to deliver holistic risk management strategies in an uncertain world. Denise has spent over 15 years working in the quantitative and qualitative risk field, helping global clients from various industries identify, calculate, and mitigate their risk.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.