With scenario modeling, manufacturers are successfully navigating the unknown by financially quantifying impact of unplanned events.

By Dan Meyer

Just over the horizon are events that will trigger great business opportunities or severe consequences. Activities such as tariffs, regulation or policy changes, political elections, climate disasters, and more will have a tremendous impact. The key is to anticipate, create, and quantifiably evaluate multiple options.

There are several approaches used to create plans and strategies. These methods help companies set expectations, budgets, production targets, and staffing requirements while preparing for business challenges.

Insights gained provide the framework to forecast growth while developing contingency. However, because none can offer reliable answers in the face of shifting variables, a growing number of companies are adopting a more dynamic approach.

Combining qualitative and quantitative approaches, scenario modeling empowers stakeholders to test and measure the financial ramifications of the alternatives and draw data-driven conclusions to confidently navigate, or leverage, the threat or opportunity. Because reliable insight comes from identifying and measuring the effects of various what ifs, it’s important to create and compare multiple iterations. Scenario modeling allows plans to be continually evaluated and refined as situations change or progress.

Automotive suppliers, for example, employ scenario modeling to blend customer releases to the plants against order volumes, vehicle inventories, and vehicle sales. This is especially beneficial in balancing procurement and production with inadequate sales projections and vulnerable supply lines.

Manufacturers who were previously going “all electric” are now embracing hybrid vehicles. This has implications for suppliers in terms of program revenue, parts volumes, workforce staffing, and other considerations which greatly impact profitability. As a result, suppliers are working to forecast the financial impact of this movement. Scenario modeling allows these companies to determine the effect on sales forecasts and the resulting need to shift resources away from cancelled or postponed programs.

From global or regional conflicts to climate disasters and labor strikes, scenario modeling allows companies to prepare for a wide variety of potential events.

Elections can have an impact long-term as incoming administrations impose, modify, or eliminate mandates, regulations, tariffs, and taxes. Consequently, manufacturers can benefit from being aware of potential outcomes, modeling the effects of these possibilities and testing and re-testing contingency plans so that they can react quickly.

On a national level, a rollback of electrification incentives and emission rules has suppliers anticipating that internal combustion engine (ICE) vehicles will continue at higher volumes while electric vehicles (EV) are delayed. But the future of automotive suppliers relies on accounting for all possible outcomes. What happens if certain states double down and uphold these mandates? And how do rising European Union regulations impact demand and production targets?

Scenario modeling aids these companies in layering in what types of vehicles might sell or be produced in the coming months. That supplier must be prepared to evaluate the options and shift gears. This might include new revenue streams, eliminating capital investments, and workforce layoffs.

In scenario modeling analysts change variables observing the impact on key metrics to explore potential outcomes. Ideally, multiple versions of these models are created to account for different or extreme scenarios, such as optimistic, pessimistic, and worst cases.

Identifying and quantifying key parameters that influence outcomes early in the process ensures a comprehensive and accurate representation of the system being modeled. Multiple attributes, such as economic, resources, technical factors, and so on must align with primary objectives and be interconnected to simulate realistic conditions.

By using a range of variables and scenarios, models account for potential variability, uncertainties, and dependencies. Robust data sources, consistency in measurement, and sensitivity analysis are essential to refine attributes and predict complex outcomes accurately. Sensitivity analysis assesses changing one variable affects outcome. This identifies which variables have the most significant impact on the result. This enables decision-makers to better understand risks, trade-offs, and impacts.

For example, a baseline budget is created for long range plan of forecasted vehicles from a third-party market volume source by applying to current/potential opportunities. What if the predicted market for electric vehicle volumes goes up, due to relaxed EV requirements?

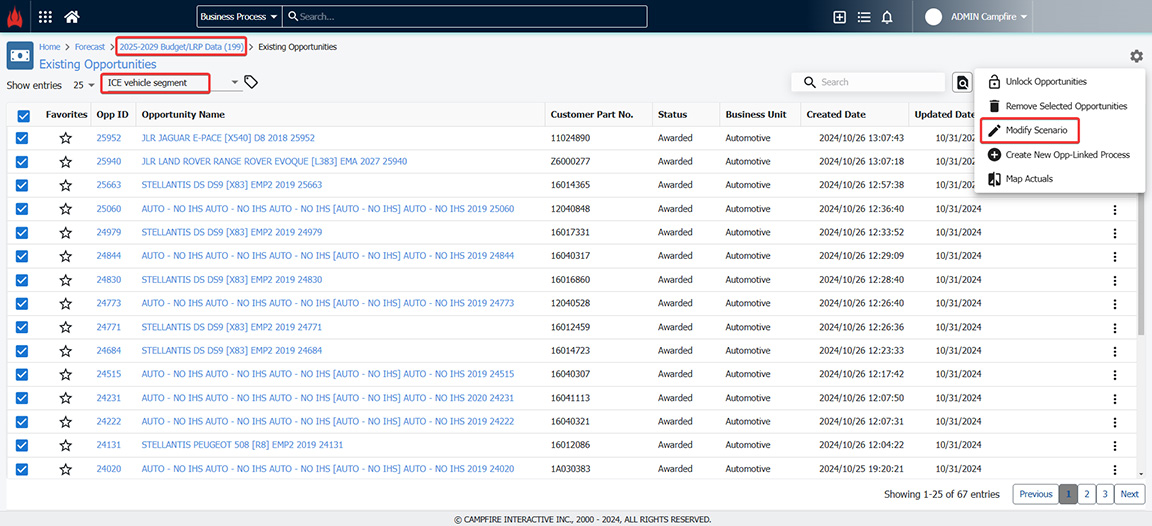

Using the “Modify Scenario” functionality in this automated approach, an automated approach, a search for ICE models can be made across the forecast, applying a factor to represent the increase in volumes. Revenues are recomputed using the new data, and the forecast can be saved as a “What-If” forecast and compared against the baseline forecast in variance reporting.

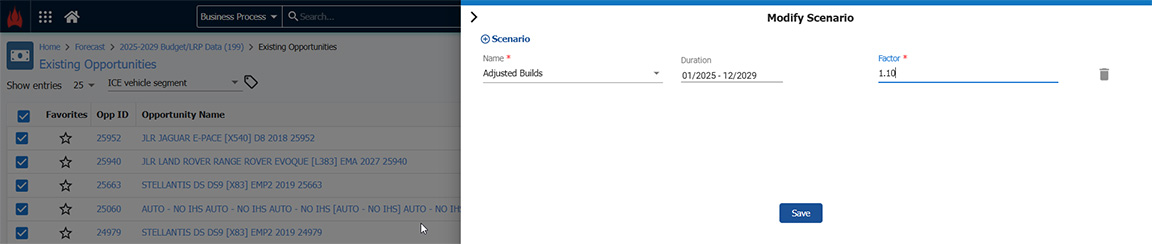

Additionally, other key input variables besides volume can be adjusted, such as material indexes, prices, and exchange rates, saved as a “What-if” forecast and compared against the baseline forecast. Variance reporting will show the effect of the scenario outcomes on important company KPIs.

Scenario modeling was traditionally a labor-intensive exercise that consisted of manually adjusting a limited set of assumptions and inputs in a spreadsheet. Because conclusions were often derived using historical data and judgment, results were generally limited in terms of both scope and depth. And since calculations are handled manually or through basic formulas, analyzing complex interactions or large datasets becomes challenging and error prone. Manual modeling relies on historical data sets which can only predict based on past experiences, not accounting for unprecedented disruptions such as changing weather patterns, political and social movements, new types of supply shortages, a radical shift in buying trends, and so on.

With an automated solution, the system becomes a repository for data. Without a centralized system, data is widely distributed throughout the enterprise in varying detail, formats, platforms, and degree of accuracy. This creates challenges in accessing the data while bringing its historical accuracy into question.

Artificial intelligence (AI) is adept at quickly handling what-if analyses across multiple variables, uncovering possible futures under varying conditions. Advanced algorithms generate multiple scenarios based on historical, real-time, and projected data offering insights to support critical decision-making in uncertain environments.

AI’s biggest contribution is the ability to continually learn and repeatedly model and refine scenarios as new data becomes available. This improved accuracy makes scenario models more actionable over time. By integrating and leveraging AI, organizations can enhance predictive capabilities, improve risk management, and make strategic choices with greater confidence in a rapidly changing world.

There are many present-day examples of AI’s ability to learn and refine.

Financial Forecasting: AI analyzes historical and real-time market data to predict future trends and simulates the impact of events like interest rate changes, geopolitical tensions, or stock splits.

Supply Chain Optimization: AI accesses data from shipping, inventory, and market demand and evaluates the impact of disruptions like natural disasters, supplier delays, or market demand shifts.

Climate Modeling: AI models are trained on climate data to predict patterns and evaluate potential interventions modeling such variables as the impact of reduced carbon emissions, deforestation rates, or alternative energy adoption.

Today’s enterprises are tremendously global, complex, and interdependent. And uncertainties come at a faster pace with even greater consequences. Scenario modeling allows companies to understand the financial impact of a wide variety of events, quantifiably evaluate plans, and take quick, decisive action.

About the Author:

Dan Meyer is President & CEO of Campfire Interactive, Inc. (www.cfi2.com). Campfire’s solutions help manufacturers identify, plan, develop, and execute their product portfolios including financially quantifying the impact of unplanned events.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.