The integration of business and operational data is critical to digital transformation success.

By Simon Coombs & Tracey Countryman

The integration of business and operational data is critical to digital transformation success. It’s a change effort spanning further than a list of tech-tasks: Successful IT-OT integrations need organizational change, data governance and cross-business collaboration.

Executives can ensure execution excellence by following seven management best practices:

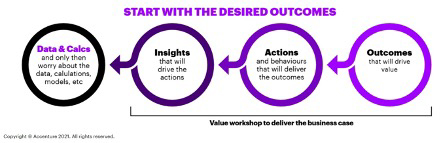

Every change effort should start with defining the expected results. Executives need to be clear about how their company’s digitization and the integration of IT and OT data will create value for the business, and they need to specify the actions expected to drive the effort. If data and insights are to create value, they must influence people and systems’ behavior – and start with that in all stakeholders’ minds.

Once executives have this clarity and alignment, then they can plan the IT-OT integration, following the steps outlined in figure 1 (read from right to left).

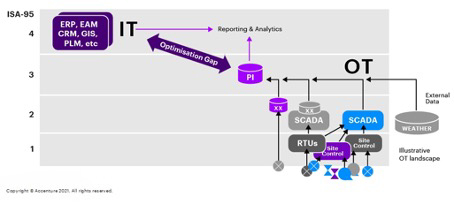

When planning the IT-OT integration, it pays to stick to the ISA-95 standard. It defines IT-OT landscapes as stacks with four layers, a view similar to how vendors typically explain their solutions.

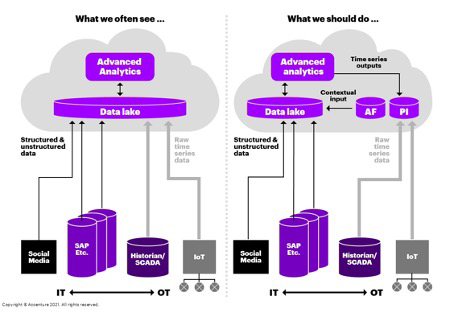

Figure 2 shows a common starting point and opportunity for many of these projects: Companies often pull together IT and OT data in their wide reports, so they’re seldom optimized for deriving insights helpful to daily operations. Seeing and then tackling this “optimization gap” is how executives will drive convergence value.

Companies’ OT landscapes tend to be quite fragmented. While IT apps are typically standardized across the enterprise, OT solutions aren’t. Most businesses engage a multitude of vendors and versions, sometimes even within a single site.

The idea of sorting it all through some homogenization effort will be tempting but in nine out of ten cases, these efforts are too cost-intensive and risky. While reducing the number of vendors will benefit supply chains and make skill-building easier, the necessary reduction projects often take years and leave the landscape fragmented over time.

Executives shouldn’t battle the chaos, but rather manage it, for example, by using “layer 3” of the ISA95 model as an “optimization layer,” i.e., to combine different IT and OT layers across the entire business. This strategy makes the OT complexity manageable while helping to reconcile the various associated security needs.

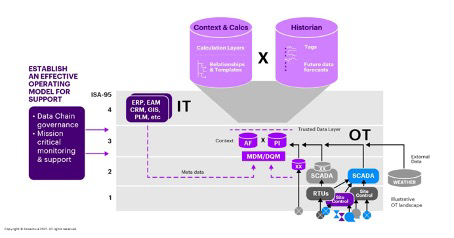

OT comes with another characteristic executives will have to manage—”time-series data”—and solve for two specific issues:

The best way to execute this is creating a “trusted data layer” where all OT “historian” data is fed into an analytical framework (figure 3). Algorithms will enrich it with contextual metadata while handling essential data quality management. If configured correctly, this also enables data-chain governance (i.e., governance from the sensor to automation controls) and monitoring plus support functionality.

The latter is especially helpful because, although most IT-OT convergence solutions work well after set-up, data quality issues tend to occur after a few weeks (often due to problems with the underlying operating model). If no-one can spot and fix these, the erosion of trust into the insights generated by the solution can be significant—and prevent operators from acting on them, ruining the ROI of the entire convergence effort.

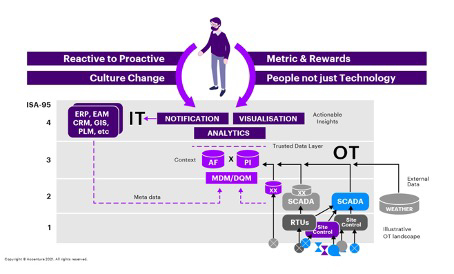

Once the trusted data layer is in place, executives can start to add “action drivers”, i.e.: analytics, visualizations, and alerts, which help the operation experts find and fix issues quickly. Remember: The IT-OT integration is merely the means, not the end. Executives must ensure the technology feeds back into human and systems behavior.

The recommendation is to integrate the IT-OT solution back into IT-led work and asset-management solutions, so IT experts can optimize workflows and interventions, allowing human experts to be kept in the loop and easily monitor how the business adopts the IT-OT solution. Both can be productive drivers of the desired changes in culture and behavior as well as help create a data-driven mindset.

Executives shouldn’t plan all analyses in a cloud-based “data lake” platform when working with OT data. High volumes of real-time, time-series data that OT generates can lower the performance of even the best cloud analytics solutions or drive hardware subscription costs through the roof. And OT data can incur steep development and support costs in cases where a standardized platform must be customized to take in highly specific data.

A hybrid solution (figure 5) is often the better choice than an out-of-the-box cloud solution. Such architectures keep historian and IoT data separate and handles raw time series data and quality management tasks themselves. They only tap the OT cloud data when they need advanced analytics—and compresses their inputs before uploading them.

The most important component for IT-OT convergence success is organizational change. Often different organizations and people have differing mindsets — specifically centralized IT teams and de-centralized site Operations — on managing IT and OT systems (figure 6). Executives must be strategic around the particularities of this cultural divide to meet their overall goals.

The rise of IoT solutions has brought most OT solutions closer to IT-like attributes IT-OT convergence. As OT becomes more like IT, change is critical to pursue a combined, centralized IT-OT organization model. This may remove direct control from plant managers’ hands and place it with off-site OT experts, but given the close link between these experts’ work and the need for on-site plant management and maintenance, both groups have to maintain a close relationship.

Simon Coombs is a managing director and lead for Intelligent Operations at Accenture Industry X. In his role, he consults clients on complex IT/OT-integration, operations digitalization and data analytics projects. Simon is an electrical engineer by training and brings more than three decades’ worth of industry and digitalization experience to his projects.

Tracey Countryman is a senior managing director and global lead for Digital Manufacturing & Operations at Accenture Industry X across all production related industries. During her 23 years with Accenture, she has primarily focused on operational improvement strategies enabled by digital solutions across the full asset lifecycle from early stage FEED to build, commission, handover and operate and maintain. This includes core elements of digital twins, digital worker solutions, MES/ MOM modernization, EHS and Maintenance & Reliability consulting.

Contact:

https://www.accenture.com/us-en/insights/industry-x-index

jens.derksen@accenture.com

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.