Manufacturers turn towards Silicon-Fluorine and other bonding molecules amid PFAS legislation.

PFAS, also known as ‘forever chemicals’ have become widely known across the globe, as legislators push to eliminate the toxic chemicals due to the harm they pose to the environment and human health. The chemical composition that is at the crux of PFAS is the Carbon-Fluorine bond, one of the strongest in nature and lasts over 50,000 years. While the focus and testing is on the PFAS specific bond, the expansion by manufacturers into Silicon-Fluorine, or Silicon tetrafluoride, and other chemical compounds allows manufacturers to be technically accurate when claiming to be PFAS-free without addressing the underlying issue, which is Fluorine. Fluorine is the piece of the equation that gives the different branches of the fluorinated chemical tree their performance in water and oil resistance, but also provides the harmful effects in large or long-lasting quantities.

Evidence has shown the negative impacts of plastics and chemical compounds, like PFAS. With a growing reliance on plastics and high-performing materials, manufacturers found the performance of Fluorocarbon chemistries that make up PFAS successfully serve a variety of industries ranging from food packaging, healthcare, textiles, automotive, and more. However, as additional research is published highlighting the dangers of PFAS, consumers are becoming more aware of these compounds in their products, forcing manufacturers to seek out high-performing, human-friendly alternatives that meet their standards.

These standards include temperature fluctuations, grease & stain resistance, along with oil repellency. Major corporations have been called out over the last few years for their use of PFAS, but now Silicon Fluorine is being used as a loophole, in some cases. While some manufacturers are pushing towards Fluorine-free chemistry to completely remove the harmful chemical, it’s important to note the hesitancy that comes along with switching from fluorinated chemistry as it has proved its reliability in products, and there are minimal alternatives offered on the market, and at commercial scale. Until there are federal regulations fully banning the chemical, states will issue their own bans but most companies will not make the change until they are forced too.

By using a silicon, zinc-oxide, or other molecule to bond with a Fluorine molecule, companies are able to accurately claim they are PFAS-free, because there is no carbon molecule attached to a fluorine molecule – an important distinction. While technically accurate when saying PFAS-Free, without removing the toxic Fluorine molecule, there is not a clear understanding of how safe this distinction is. Many products contain Fluorine and are also claiming to be PFAS-free. However, it’s been made clear that the textile industry is heavily introducing silicon fluorine as a substitute for traditional fluorocarbon products. It’s likely that the majority of companies that are advertising any type of stain resistance, especially with oil, are using a fluorinated molecule. That is unless they go the extra mile to transition to sustainable, PFAS + Fluorine-free coatings that replicate historic performance standards without the harsh chemicals.

Recent headlines have emphasized the contamination of PFAS in water, and while testing for these chemicals in water has greatly progressed, there is no testing infrastructure in place for other forms of PFAS. It’s a challenge finding PFAS testing outside of water that is accurate. In order to detect PFAS, liquid samples must be submitted, or costly chromatography must be performed. The fourier-transform infrared spectrum (FTIR) has been used to identify the amounts and types of functional groups according to their wavenumber and the absorption peak intensity. The textile industry is seeing more testing being done versus other industries like food packaging, and cookware even though food packaging regulations are far stricter.

On the other hand, Fluorine is more easily detectable, but the chemical group is still flying under the radar because it has not yet reached consumer attention. PFAS continues to make headlines and be the EPA’s focus as it pertains to chemicals.

While there are limited alternatives on the market, manufacturers should note that industrial-scale Fluorine alternatives are more accessible than they might’ve thought. Whether it’s food packaging, automotive, healthcare or textiles, there are companies developing solutions that are environmentally friendly and health-conscious for humans.

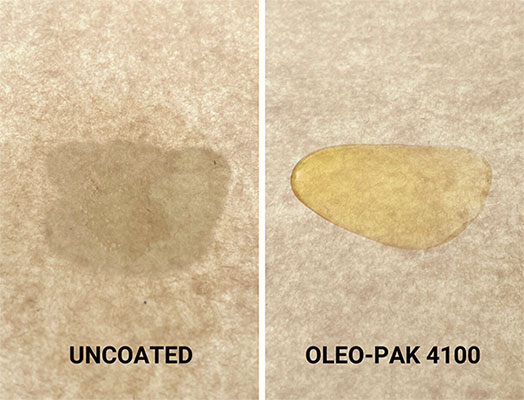

While it’s a difficult transition for manufacturers to leave Fluorinated solutions, commercially available solutions are viable and even meet the same performance standards that made PFAS popular to begin with.

About the Author:

David Zamarin is the founder and Chief Executive Officer behind DetraPel Inc, which just celebrated its 10-year anniversary. David’s passion for wellness and technology drives the company’s mission to develop innovative formulas that offer superior barrier technologies while removing the reliance on Fluorine in industrial coatings. While David spends most of his time developing DetraPel and its commercial and industrial brands, David seeks to give back to future generations by teaching entrepreneurship.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.