Best practices manufacturers can put in place to protect the health and safety of their employees while managing staffing shortages.

By Terri Mock, Chief Strategy and Marketing Officer, Rave Mobile Safety

Manufacturers have been dealing with labor shortages for months now, and with omicron worsening the situation for employers, staffing needs are only increasing. According to the Wall Street Journal, around 70,000 to 90,000 workers or more will need to be added by 2025 to meet the workforce needs for fabrication expansion in the U.S. alone. But with talent pipelines drying up, many are worried they simply won’t have the people available.

While manufacturers are looking to fill vacancies, they may be less focused on the safety of their current staff, who are having to work harder and longer to fill the gaps. On top of overworked staff, many companies are also having to hire new, green graduates to fill job openings. These less experienced new hires increase risk as they don’t have the on-site expertise to rely on if a safety concern arises.

To better communicate about COVID-19 cases and fill empty shifts, manufacturers should establish strategies to check in on employee wellbeing and use technology to help facilitate those measures. Especially amidst staffing shortages and the ongoing pandemic, what best practices can manufacturers implement to better protect and communicate with employees?

Daily health checks are an effective strategy to stay on top of COVID-19 cases (and symptoms), check-in on employees’ mental health and let them know that the company cares about their wellbeing. With the right tool, these checks don’t require burdensome time or resources from managers, and they can get the information they need about their team to be better leaders.

Manufacturers can send out a daily health questionnaire directly to employees’ phones and help prevent the spread of COVID-19 by screening if they are sick before they come to work their shift. With this data, manufacturers can see when symptoms were reported and by whom if they need to do contact tracing. In the end, it’s easier to deal with the disruption of one employee out of work than it is to have them come in and infect the entire team.

As manufacturing employees work overtime, this leads to burnout and exhaustion which contribute to high turnover. In physically demanding roles, it’s important for employers to prioritize their teams’ wellbeing. In fact, a lack of respect towards floor and production workforce members was cited as one of the main reasons manufacturing employees left their jobs. Manufacturers can lower turnover and the costs associated with it by checking in on how their teams are feeling each day and following up when it’s needed.

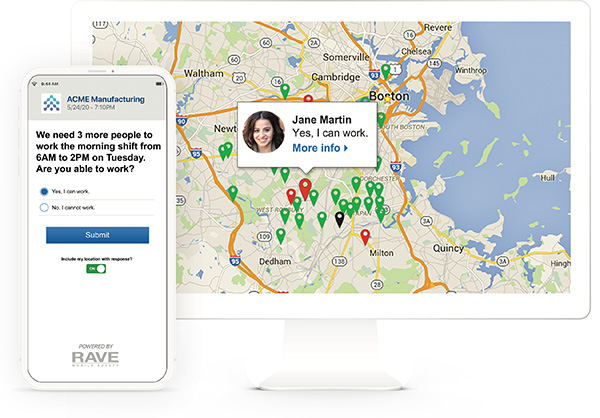

Once manufacturers know who can and can’t come into work, they can use polling features in mass notification solutions to quickly see who may be available to work, ensuring proper coverage. A mass notification system can send messages to employees preferred method of communication, whether it’s SMS, email, voice, desktop notification or other channels. With just a few clicks, employees can quickly be notified of open shifts and respond if they are able to come in.

Finding coverage during the manufacturing labor shortage is more difficult, and teams need the tools to streamline the process as much as possible. Calling individuals or sending emails to employees who may be available is overly time-consuming and recipients may not see them in time. With direct text notifications, manufacturers can reach the right people faster.

This is critical, because ensuring coverage means improved safety. When there are gaps in critical roles, employees have to be responsible for too much at once which can lead to avoidable mistakes. Ensuring employee safety takes the full team working together with everyone playing their role and staying focused.

To keep employees safe, manufacturers also need to communicate quickly – whether about the coronavirus or another emergency. The right tools can help get employees the information they need to stay safe and efficient. If a safety protocol needs to be initiated, a mass notification system can keep employees informed on what is going on and what is expected of them.

During labor shortages, there may be fewer employees available to respond to safety incidents meaning manual communication methods will be less effective. Having a solution in place before an event occurs enables employers to be vigilant about communicating so that employees know what steps to take to minimize the risk.

Frequent communication also helps employees feel informed on relevant workplace updates. As the pandemic has made it difficult to maintain networks, communication is key to keeping everyone up-to-date on policy changes, safety protocols and COVID-19 requirements such as vaccines or testing.

While the ongoing labor shortage continues to pose challenges for manufacturers, keeping employees safe does not need to be one of them. With the right tools and strategies, manufacturers can maintain productivity without compromising employee safety.

Terri Mock oversees strategy, product and marketing at Rave. She is an executive leader with achievements in delivering revenue growth, driving go-to-market, innovating products, and scaling operations from high-tech startups to global companies.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.