Remote visibility and automation to empower the essential mobile workforce post COVID.

MDM tools provide a means to remotely interact with the mobile user’s device, pull log files, and update security, software and firmware.

The COVID-19 crisis has uncovered major shortfalls in what were once viewed as stable processes. Ultimately, these gaps exposed by the pandemic will strengthen our supply chains, people, and processes. But to get there, we must examine what we know, what we don’t, and who is impacted.

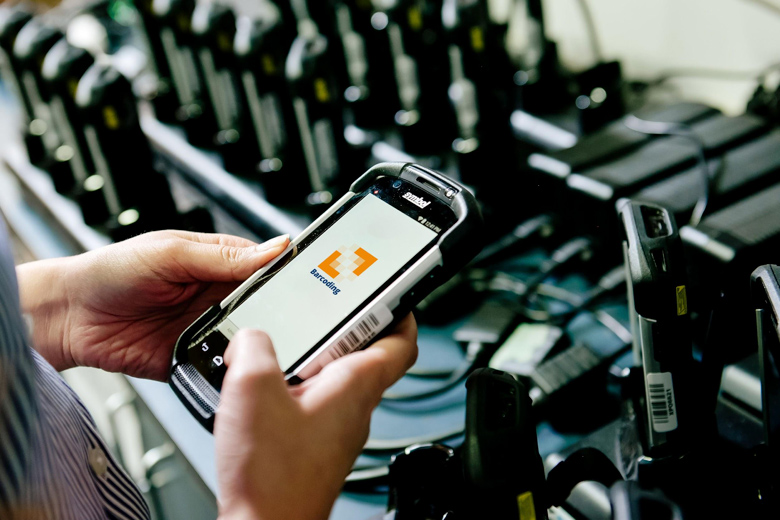

Warehouse, transportation, and delivery workers, now referred to as the front-line or essential workers, are receiving overdue attention, even by the mainstream media. These individuals are the power behind the supply chain and our economy.

Their primary tool is the mobile computer and that’s why this group is known as the mobile workforce. And being able to effectively support the mobile workforce is a business’ window into, well, almost everything that’s going on anywhere in its supply chain.

For decades, corporations have made significant investments in technology, infrastructure, and people who enable and support the mobile workforce. Ironically, where corporations often fail to invest is in the detail — the processes and maintenance required to keep the larger enterprise running, such as remote visibility and proactive monitoring and analysis. Instead, there is a reliance on manual processes and tools to maintain and support these larger investments. With the introduction of social distancing and remote work, companies are starting to experience these pain points:

How do these realities impact the business? Front-line mobile workers quickly become frustrated and their workflows disrupted.

Greg Henry, Vice President of Client Services for Barcoding Inc., a mobility partner to companies like DHL Supply Chain, explains, “When there are gaps in communication between the front-line mobile workers and supporting IT teams, costs and tensions escalate quickly, cutting right into the top and bottom lines of the business.”

Patrick is a mobile worker in a food manufacturing facility. He uses his mobile computer to scan packages as another team member loads them on to the delivery truck. After an hour, his mobile computer screen goes blank and locks up, forcing him to stop, reboot and log in again, losing several minutes. He is frustrated but cannot stop to report this because the trucking company is already charging his company for wait time.

It isn’t until the next day when Patrick gets a chance to report these issues. Unfortunately, there is no record of the problem or means to recreate it. If Patrick keeps complaining, it’s possible that someone will show up onsite to try to see his problem occur, but this will set off a long trial and error process. Post COVID-19, this interaction could also present a potential health risk to both the IT technician and the mobile worker who need to show up onsite.

Why can’t Patrick use his mobile computer to send the IT team data about his problem so they can fix it remotely? And, more importantly, shouldn’t there be an automated way for the IT team to be alerted to this issue?

Looking ahead, enterprises supporting a mobile workforce and complex mobile infrastructure can proof for the future by taking two critical steps:

Utilizing mobility partners who can curate these technologies and build services around them facilitates strategic integration for all key players. “What makes this possible is that, while these technologies are advanced, they are designed to be easy to implement and manage in any mobile architecture,” explains Henry. “A strong partner can deliver measurable value to both the front-line mobile workers and the CIO.”

Three technologies and services are critical to achieving these efforts:

Investing in these support systems will not only strengthen the supply chain to weather future challenges, but reap measurable productivity rewards. For the post-COVID-19 supply chain, these tools and partnerships will serve to keep essential workers moving products swiftly and safely.

Shari Christofferson

About the Author

Shari Christofferson is President of Connect Inc., a digital technology company that has been innovating in supply chain mobility for over 30 years. Her role at Connect has included a customer-centric approach to market research and product development focused on advancing mobile enterprises past challenges with relevant data analytics, process automation and AIOps technology. Prior to Connect, she worked with technology entrepreneurs supporting market development and expansion in local and global markets.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.