Thirty-seven percent of manufacturers say the pandemic is a catalyst for increasing automation, a new survey from MC Machinery reveals.

CHICAGO— While 37 percent of manufacturers say the pandemic is a catalyst for increasing automation, the primary drivers for adding and expanding automation include the need for increased productivity and a shortage of skilled workers, according to a new survey from MC Machinery.

More than 160 manufacturers participated in the online survey between Oct. 7 and Oct. 16. The respondents represented manufacturer including job shops, automotive, food, mold & die, aerospace, medical, and energy. Nearly 85 percent work for or own manufacturing companies with under 200 employees.

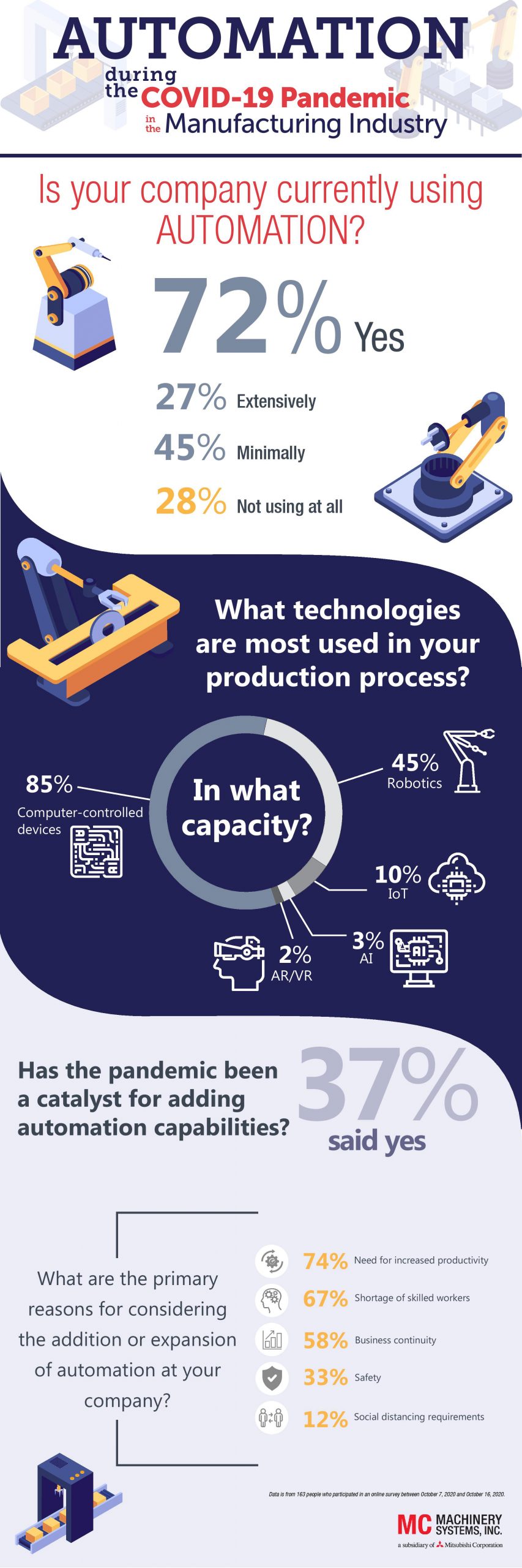

About 72 percent of survey respondents said they are using automation, with 45 percent are using it minimally and 27 percent extensively.

The automation or digital technologies most used in the production process are computer-controlled devices (85 percent), robotics (45 percent), IoT (10 percent), AI (3 percent) and AR/VR (2 percent.)

Almost 30 percent of respondents said they are planning to add or expand automation capabilities to the production process in the next few months.

The main reasons for adding or expanding automation were cited as:

A May 2020 MC Machinery survey found that 62 percent of manufacturers believed the pandemic was revealing opportunities for manufacturing innovation. The biggest opportunities cited included collaborative manufacturing (29 percent) and automation (21 percent).

“This survey shows how important automation is to the future of manufacturing,” said MC Machinery Vice President of Sales and Marketing Bill Isaac. “While automation was increasing before the pandemic, the past few months have illustrated the importance of automation to long-term success.”

About MC Machinery

Headquartered in Elk Grove Village, Ill., MC Machinery Systems is a premier manufacturer of laser, press brake, wire EDM, sinker EDM, milling, high-speed VMC, automation equipment, and consumable products. A subsidiary of the Mitsubishi Corporation, MC Machinery serves industries including aerospace, mold and die, job shops, medical, and energy. Along with manufacturing industry-leading products, MC Machinery provides an advanced, responsive service network and the robust production monitoring and support solution remote360®. Visit www.mcmachinery.com for more information.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.