Strategic technology implementation can drive efficiencies in the supply chain and strengthen companies’ bottom lines.

By Melissa Twiningdavis, senior managing director, Accenture

Leaders need to approach technology with the aim of driving value. While CSCOs are under pressure to deepen resilience and make operations a competitive strength, that doesn’t happen without the right combination of processes, technology and talent.

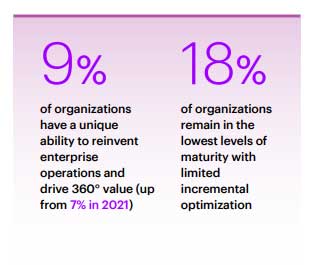

Of course, this is not a new idea. When the pandemic forced workforces to operate remotely, many companies sought ways to automate processes to sustain rigor while increasing efficiency. However, recent Accenture research shows that only 9% of organizations harness AI capabilities to drive operational value across functions. And simply investing more in digital technologies does not guarantee resilience or improved business outcomes.

As organizations adopt more technology solutions, the business processes associated with tasks tend to become more complex. This is especially true considering the interconnected and interdependent nature of the supply chain. Enhancing performance with AI starts with a clear strategy, mapping opportunities where automation can make the biggest impact and recognizing where progress can be made across talent, data, processes and use across the organization.

Some organizations have even applied digital twins to simulate process changes. This first step offers a bird’s-eye view with virtual representations of current procedures, allowing for greater insight into inefficiencies caused by process deviations, duplicate steps and other non-value-added activities. For example, Mars has been trialing digital twins for use in manufacturing operations to reduce instances of over-filling packages, a common problem in the food industry.

Digital twin capabilities can bring companies data-based insights that help them audit, analyze and improve supply chain processes before automating them. Essentially, if simply automating old processes can amplify the low-quality output of those already-flawed processes, when businesses gain a holistic view of operations and pinpoint process flaws first, they can actually focus on adopting the right technology in the right places to reach peak productivity.

Many supply chain processes are monotonous and prone to human error. After carefully evaluating existing processes to uncover inefficiencies, companies have much to gain from starting their process automation journeys in these three areas:

While automating a few processes alone can help create a more transparent, connected and resilient supply chain, a clear and strategic roadmap that prioritizes the needs of key stakeholders is required to scale automated operations. A company’s priority in this case should be to simplify and supplement employees’ work, allowing them to focus on more complex, thought-based problems in place of manual, error-prone work.

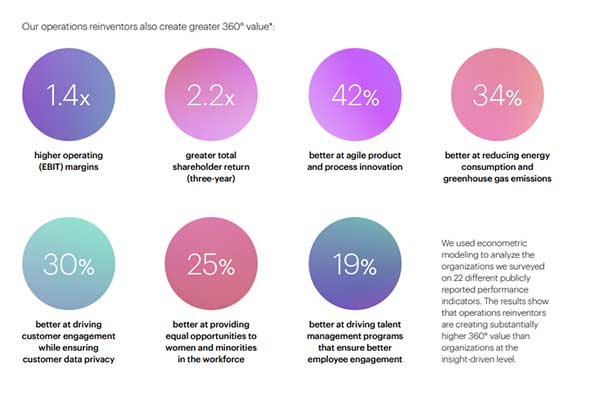

When deployed successfully, supply chain process automation ultimately drives bottom line impact. Accenture’s recent report found companies that thoughtfully and strategically reinvent their operations saw up to a 1.4X higher operating (EBIT) margin over peers, 42% more efficient in product and process innovation, 34% more sustainable and 30% better customer engagement.

In this rapidly changing landscape, it’s critical for companies to focus on enhancing automated operations to create a competitive advantage and maintain a resilient supply chain.

Melissa Twiningdavis is a senior managing director of Supply Chain Operations at Accenture.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.