Tracing testing data is an essential part of manufacturing as it controls the entire production process and ensures product integrity.

Tracing testing data is an essential part of manufacturing, as it allows to control the entire production process and ensure product integrity from the initial manufacturing stages to distribution. This provides a comprehensive overview of all manufacturing activities, of the results obtained, and any issues identified during the process, avoiding the dreaded consequences of putting on the market products that don’t meet production standards.

The traceability of testing data is particularly important in sectors in which product safety and quality are paramount, such as in the pharmaceutical, automotive, and aerospace industry.

With the advent of industry 4.0 and the interconnection of manufacturing systems through technologies such as robotics, AI, and IoT, traceability has become even more necessary.

The digitalisation of the manufacturing processes has changed the approach to data tracing. The increase in the amount of data now requires the use of centralised databases in addition to the labels applied directly on products, which alone are no longer sufficient. These databases have become very useful because they allow to collect a great amount of information and store it in a single place that can be accessed from different areas of a production process, making it available at any given time wherever it may be needed.

The use of standard industrial protocols, such as the popular Profinet, Modbus, EtherNet IP, EtherCAT and most recently OPC UA, has hugely simplified the interconnection between devices in the manufacturing industry as they are widely used and easy to install and operate. For example, the connection between a leak tester and an external PLC makes use of these protocols.

Despite these new tracing systems, printing unique labels is still essential in the biomedical and pharmaceutical industry as batch traceability is a guarantee of patient safety.

For example, each phial or bottle of medicine can be labelled with a unique bar code that allows to trace the production batch of origin.

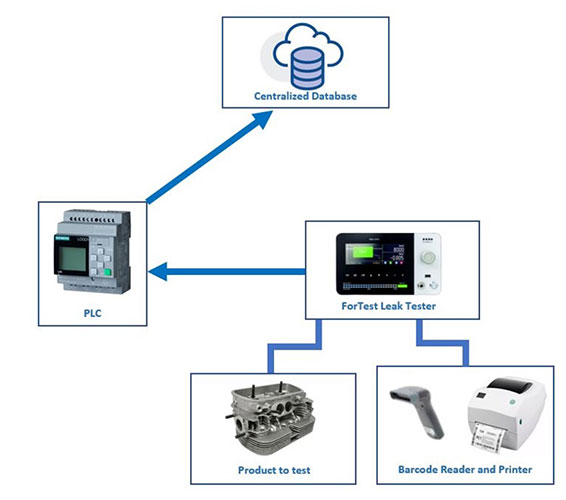

In recent years, ForTest, leader in testing equipment for the industry, has made its leak testers totally compatible with the latest tracking systems. This means that its equipment supports the printing of barcode labels with testing data as well as the connection to barcode readers. The latter allows to read and save product codes on the device.

ForTest also provides support for standard industrial protocols, such as Modbus, Profinet, Ethernet IP, Ethercat and soon also OPC UA, allowing ForTest equipment to communicate with almost any device on the market, for example PLC and PC.

ForTest equipment also allows the use of multiple tracking systems at the same time. For example, you can use an external PLC as well as a label printer connected to a barcode reader.

In the case described above, the leak tester will be connected to the part that has to be tested, which will be labelled with a sticker with a unique barcode that identifies it.

In this case, the PLC will communicate via Profinet or EtherNet IP and will automize the testing, the data collection and the data saving process on a database.

To summarise, companies hugely benefit from having the best possible tracing system and the full compatibility that ForTest equipment offers, because it allows them to increase control on their manufacturing processes and avoid any possible issues.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.