Your path to the ultimate coding & marking solution with free samples and premium-quality advice.

Tuttlingen (Germany) – At its recently opened Application Center, LEIBINGER is offering printing samples within three working days as a free service. State-of-the-art technical equipment and advanced resources enable exceptionally realistic sampling. Customers benefit from a comprehensive package of tailored printing technology and ideally matched ink for their specific application – a one-of-a-kind offering in the coding & marking industry.

The LEIBINGER Application Center creates print samples in line with specific customer requirements. In other words, companies from all sectors can now send in samples of their products, which are first analyzed and then printed and tested with different inks. The samples provide a perfect decision-making tool for the right coding & marking solution, which customers can use to get started as quickly as possible. To this end, the Application Center team is in close contact with customers throughout the entire sample printing process.

“Every material has different properties, and every ink behaves differently on them. This is why it is essential to test ink on the specific materials so that customers can assess the results for themselves,” explains Dr. Bastian Klose, Head of the LEIBINGER Application Center. Since July 2024, the former sample printing facility has been located in new premises with more space and advanced, state-of-the-art equipment. “We decided on the term Application Center because we have created many new possibilities here to produce the best prototypes for our customers in a way that replicates real-life processes,” explains Klose.

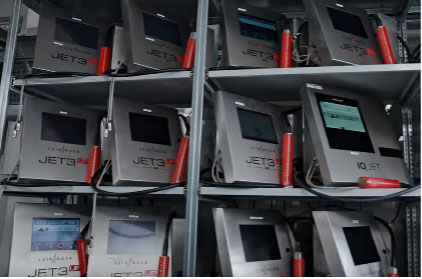

The Application Center offers an exhaustive portfolio of services: Customers receive their printed samples back within three days – entirely free of charge. To make this happen, the Center uses a fleet of some 70 printers. “This is truly exceptional in our industry,” explains Klose. “And it is only possible thanks to LEIBINGER’s fully automatic nozzle sealing technology, which ensures that the ink never dries. Press the button to print samples, and the nozzle simply closes. Every printer is ready for use at any time at the push of a button, even when highly pigmented inks are used,” adds Klose.

Using IR spectroscopy, LEIBINGER can precisely determine the material class of the product to be sampled. With a little skill and expertise, additives in the material can even be identified in some cases. This is essential for selecting the ideal ink for the material, as the specific properties of the ink and material influence each other. If needed, the materials can be pre-treated directly at the Application Center – using processes such as Corona or Plasma – to modify the surface properties of the materials and optimize ink adhesion.

The Application Center is also true to the industrial process when it comes to speed. A specially designed acceleration unit enables the team to create print samples at defined speeds, simulating a real-life production environment. “After we have created the samples with the selected inks, we prepare a detailed sample report,” explains Klose. “This is provided to the customer along with the printed samples.”

The LEIBINGER ink portfolio includes some 70 inks. They are developed in the cutting-edge ink laboratory, which has had its own building since 2022. The new Application Center has now been added – to ensure short distances, seamless coordination and ideal working conditions. The laboratory team, with its many years of experience, develops a wide range of inks, including sterilization-resistant ink, fluorescent security ink, FDA-compliant ink, food-safe ink and many others. “Our ink laboratory is the birthplace of LEIBINGER inks,” says Klose. “This is where we develop customized solutions for different markets, ranging from the food industry to fast-moving consumer goods (FMCG) and even cable production.”

Dr. Bastian Klose highlights that LEIBINGER goes far beyond the standard in the coding & marking market – also in terms of customer service. “We provide our customers with printing solutions that are perfectly tailored to their specific application.” Thanks to comprehensive advice and sample production that replicates real-life processes, customers can be sure that they are receiving the very best solution to meet their coding & marking requirements.

If you would like to find out more about the printers and inks from the LEIBINGER portfolio, please visit the LEIBINGER website: www.leibinger-group.com

About Paul Leibinger GmbH & Co. KG (LEIBINGER)

LEIBINGER is a globally operating specialist in coding & marking systems with headquarters in Tuttlingen, Baden-Württemberg (Germany). The third-generation family-run company, founded in 1948, develops and produces industrial inkjet printers as well as inks for various applications – with a workforce of close to 300. Innovative technologies and an exceptionally high standard of quality are what distinguish LEIBINGER’s advanced coding and marking solutions. As the inventor of a groundbreaking nozzle sealing technology that makes ink-based marking systems much less susceptible to contamination, LEIBINGER ensures greater productivity in the manufacturing of food and industrial products – with tens of thousands of successful installations worldwide. A global network with some 150 distribution partners and subsidiaries in the US and China ensures that LEIBINGER is ideally positioned to maintain close relationships with its many customers worldwide.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.