Ongoing supply chain disruptions prolong component shortages, causing production constraints for Original Equipment Manufacturers (OEMs).

By Thomas Kowal, President, Seraph

Original Equipment Manufacturers (OEMs) are often exposed to critical business risks due to inherent vulnerabilities, which can include quality failures, financial risks, supply chain interruptions, and cybersecurity breaches, among others.

A clear example of supply chain disruption is the automotive industry’s semiconductor chip shortage, which has gone from a seemingly minor issue when the first whispers were heard in December 2020, to a full-blown crisis that continues to make headlines worldwide.

Amid the auto industry’s persisting struggles with limited inventory due to continued shortages of computer chips, consumers have largely been forced to deal with prices rising 12% year over year, according to the most recent data from the U.S. Bureau of Labor Statistics.

The automotive industry is extremely complex – it is estimated that the annual production level of vehicles worldwide is 100 million, and each vehicle has approximately 30,000 components. The impressive size of the industry and the revenue generated throughout the supply chain places automobile manufacturing among the top 5 largest industries in the world. This complexity, coupled with unmatched pacing and costly downtime penalties (over $25,000 to shut down OEM production) creates a high-risk and high-pressure environment.

With razor-thin margins due to the fiercely competitive automotive market and over-capitalized supply base, providers are taking risks that can generate some short-term cash. If these risks are miscalculated, it can result in tens of millions of dollars in losses over the life of a program, which are often unrecoverable and felt throughout the organization.

Another case of crisis to highlight is in the aviation industry, where it has been learned from investigations carried out by the National Transportation Safety Board that most accidents and crises were avoidable. Incidents normally stem from pilots taking too much risk or lacking detailed planning due to:

Comparing the aviation crisis to the one affecting the auto manufacturing industry, we see that it stems from an overconfidence in the project, technology and manpower readiness.

As in the aviation industry, it is most often the human factor that causes the crisis. Employees are too afraid for their job security to speak up. Those that do speak up are not always listened to, whether a tier one program manager or plant manager who clearly expresses their concern of risk to the executive who still decides to delay spending on equipment, or the co-pilot advising the captain not to go through those thunderstorms.

Once in a crisis, it is not sufficient only to know what needs to be done, but also have the experience and discipline to complete the how. In the end, it takes courage and leadership to avoid a crisis.

At Seraph we have analyzed the top 5 causes of an OEM crisis:

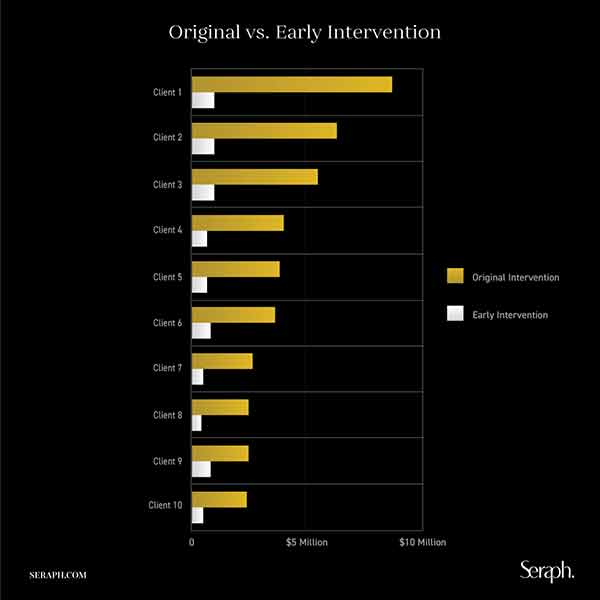

These five causes demonstrate the importance of companies being prepared for early intervention, internal team reviews, and internal sourcing reviews to avoid crises in production, logistics, and in the quality of their processes. To complement this, recent data from Seraph studies show that early intervention by companies is about 10x less expensive than the extreme impact of reacting late, as late intervention results in more effort and cost to correct problems.

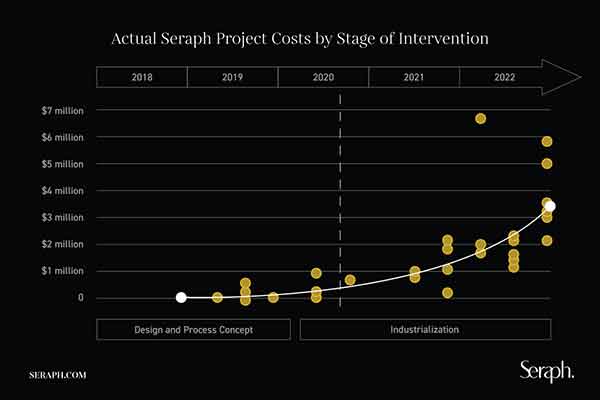

The greatest impact to ultimate cost, and eventual product launch success, occurs in the earliest stages of the program’s life, prior to the obvious derailing of project timelines. For this reason, it is important that companies adjust their plans along the way and thus be clear about the critical points that must be worked on in the near term.

Thomas Kowal is the President of supply chain, restructuring and manufacturing turnaround consultancy Seraph. Thomas has two decades of extensive management and sales operations experience in the Automotive Industry.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.