As customer preferences evolve and new regulations surface, 2025 will be a pivotal year in packaging – here are four key trends to watch.

By Matthew Wright

Staying ahead in the packaging industry requires more than merely keeping up with current trends—it requires proactive adaptation and innovation. As customer preferences evolve and new regulations surface, 2025 is shaping up to be one of the most pivotal years in recent history for the packaging industry. Below are four key packaging trends that will drive urgency and reshape the landscape for businesses in the coming year.

Sustainability continues to dominate discussions in the packaging world, and a major shift toward alternative materials is underway. With packaging affecting every brand and consumer, shifting to more sustainable practices is a game-changer when it comes to long-lasting sustainable change. Consumers and regulatory bodies alike are prioritizing packaging that minimizes environmental impact—whether through biodegradability, renewability, or recyclability.

A trend that has made its mark in recent months is the idea of “paperization” where companies replace plastic with paper or fiber-based materials. Although these materials can reduce long-term waste and ocean pollution, their means of production and transport can often lead to higher resource consumption and greenhouse gas emissions.

As companies explore alternative materials it is critical that they consider end to end environmental impacts of various options. Some other materials companies may consider are:

By adopting more sustainable materials, companies will not only improve compliance but also build brand equity by aligning with sustainability-conscious consumers.

Around the globe, the regulatory landscape for packaging is growing increasingly complex. From single-use plastic bans to Extended Producer responsibility (EPR) laws, companies are finding the need for sustainable change more relevant than ever.

With these laws on the rise around the globe, companies must reconsider how they are currently managing packaging data and reporting requirements. Because these regulations vary widely by region, it adds an even greater challenge and need for accountability. With new regulations going live in 2025, this is a perfect opportunity for companies to re-evaluate how they are going to comply with sustainability requirements.

Companies may consider becoming more informed in the following areas of legislation:

By implementing robust data management tools companies can streamline compliance and reporting, navigating sustainability requirements with ease. These tools will not only help companies better manage their data but can also help businesses proactively address regulatory demands rather than merely reacting to them.

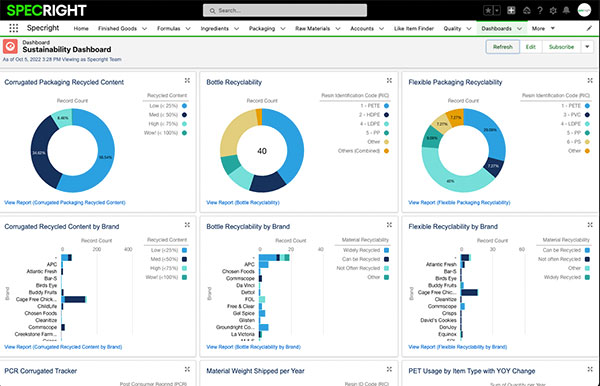

Over the years recyclability has evolved from a niche concept to a mainstream one. Conscious consumers are on the rise, demanding companies to be transparent about their packaging. This in conjunction with governments and industry organizations pushing for higher recycling rates is challenging companies to look at recyclability from a new lens.

Brands can build trust and loyalty by clearly communicating recycling instructions, through partnerships and initiatives with organizations like How2Recycle, which standardizes labeling for proper disposal. Beyond consumer-focused efforts, industry groups such as the Australian Packaging Covenant Organisation (APCO) are working toward ambitious recyclability goals that will influence global standards.

We are also seeing a rise in innovative recycling methods like advanced and chemical recycling methods. With these technologies, landfilled packaging materials can be recovered, encouraging a circular economy. Companies that prioritize recyclability in their designs and processes will not only meet compliance standards but also position themselves as sustainability leaders.

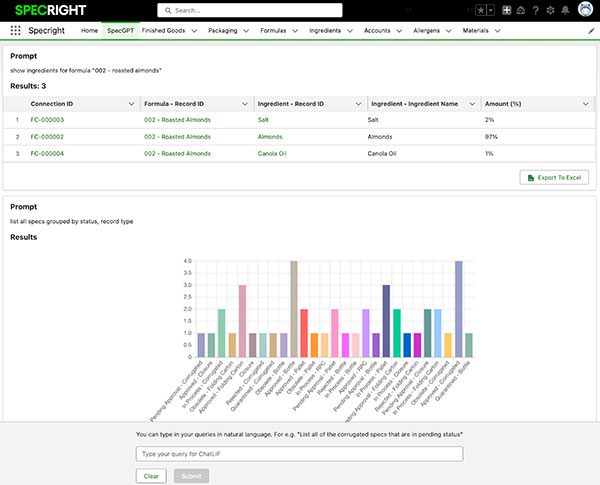

Artificial intelligence (AI) and machine learning (ML) are transforming the packaging sector by optimizing operations and enhancing decision-making – bringing the phrase “work smarter, not harder” to life. Manufacturers may see the following benefits when using these tools:

AI-driven tools are also revolutionizing data accessibility. For instance, AI-powered chatbots like SpecGPT offer instant access to complex specification data, enabling faster decision-making. By leveraging AI solutions companies can reduce costs, improve accuracy, and stay competitive in today’s rapidly evolving market.

With innovation, compliance, and sustainability on the horizon, the packaging industry is headed in an exciting direction. As the packaging industry shifts it is essential that companies address trends like alternative materials, regulatory readiness, and recyclability. To tackle these changes head on it is critical that companies leave outdated systems like spreadsheets behind and start building a solid digidata foundation.

By embracing digitized platforms for data management and sustainability tracking, businesses can unlock new opportunities to innovate, meet consumer demands, and adapt to changing laws. As the industry moves forward, staying proactive will be the key to thriving in 2025 and beyond.

About the Author:

Matthew Wright, founder & CEO of Specright, leads the first cloud-based Specification Management platform, recognized by Fast Company, Gartner, and as a top workplace. Author of The Evolution of Products and Packaging, an Amazon Hot New Release, Wright brings over 25 years of packaging expertise, including leadership roles at International Paper, Temple Inland, and rightPAQ. He has led multiple M&A deals and serves on the MSU School of Packaging Advisory Board, previously advising Cal-Poly San Luis Obispo.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.