Volume 21 | Issue 1

Click here to read the complete illustrated article as originally published or scroll down to read the text article.

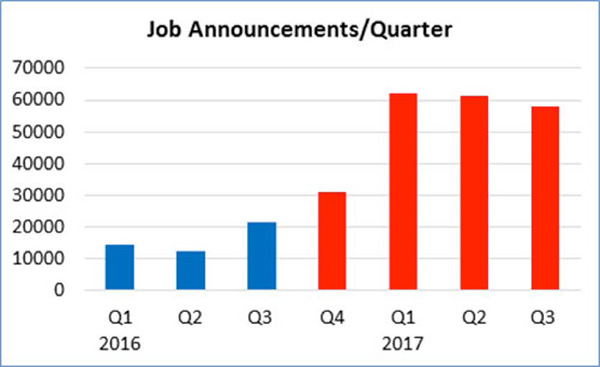

The combined reshoring and foreign direct investment (FDI) trends grew by more than 10 percent in 2016, adding 77,000 jobs and exceeding the rate of offshoring by about 27,000 jobs. The rate of jobs coming from offshore accelerated further in 2017, up 200+% since the 2016 presidential election (Fig.1). This trend has helped drive a manufacturing workforce that is now about 2 million higher than would have been projected in 2007.

This is exciting progress, but there are still huge opportunities and challenges to bringing back all of the four million to five million U.S. manufacturing jobs still offshore. The country needs companies to do the math with TCO (Total Cost of Ownership) when making location decisions. A Purdue Manufacturing Extension Partnership (MEP) Center study shows that “better total cost of ownership decisions” was the top-ranked area of concern for companies. Here are some actions that we can take together to accelerate the use of TCO and the rate of reshoring.

Several trends are driving the shift from offshoring to reshoring: the rising costs of offshore production; the impact of distance on innovation, flexibility, responsiveness, inventory and availability; improved competitiveness via automation and lean; and the increased use of the more sophisticated TCO model to quantify the hidden costs and risks of offshoring. Companies are increasingly deciding to use a “local for local” strategy and bring production and sourcing closer to home.

The economic logic of TCO is built around the savings achieved by producing or sourcing locally. The savings from low, but rising, offshore wages and purchase prices are increasingly offset by dozens of hidden costs. To help quantify those costs, the Reshoring Initiative website provides tools to help companies decide whether their overhead will come down more than their manufacturing cost goes up when sourcing locally. Use the Total Cost of Ownership Estimator® to help your company more accurately assess the total company impact of offshoring or reshoring decisions.

Our user data shows that, under current conditions, if companies use the TCO Estimator instead of price to make their decisions, they can reshore an average of 25 percent of what they have offshored and improve their profitability. The TCO Estimator typically closes a 15 to 20 percent price gap, but some companies find that the analysis is worthwhile even if the gap is as much as 50 percent!

Use TCO to make a strong case when selling against offshore competitors. Sixty percent of companies make sourcing decisions based on rudimentary metrics, such as wage rate, ex-works price or landed cost, often resulting in a 15 to 20 percent understatement of actual offshoring costs. The TCO Estimator is a free online tool that helps companies account for all relevant factors— overhead, balance sheet, risks, corporate strategy and other external and internal business considerations—to determine the true total cost of a part or assembly.

When you find yourself competing with a lower-priced offshore product, we suggest offering to help the customer compare the TCO of your offer vs. the lower-priced offshore offer. Ask about offshore-sourced products that are causing the customer problems, such as late deliveries, poor quality, intellectual property theft, excess inventory, lost orders and travel costs. Buyers often ask a salesman, “Can you match the Chinese price?” Your response should be, “Maybe not, but let’s see if I can offer you a lower total cost that increases your profitability.”

The First National Reshoring Award was won by Mitchell Metal Products, Merrill, WI. The Reshoring Initiative, in conjunction with the Precision Metalforming Association (PMA), invites companies that have successfully reshored products, parts or tooling made primarily by metal forming, fabricating or machining to compete in the second National Reshoring Award (http://www.pma.org/sourcingsolutions/). There will be one award for buyers and one award for suppliers. You do not have to be a PMA member to win. See if your reshoring is eligible. Use TCO to evaluate reshoring an eligible product. The deadline is September 1, 2018.

The Reshoring Initiative and Plante Moran are launching the “Manufacturing Reshoring Survey” (https://hbb.qualtrics.com/jfe/form/ SV_9Liu8h9lQw1oElf) to examine the overriding issues and national policy changes needed to impact plant location and sourcing decisions. Past surveys tell us whether companies have reshored or will reshore and why. This survey focuses on how much companies have offshored and what national policy changes would motivate them to reshore X% of their offshoring.

We will offer the survey results to the administration and Congress to drive policy so the 75% of offshoring not currently suitable for reshoring can be reshored. We hope your company will complete the survey. The deadline is February 20, 2018.

We are about to launch the Import Substitution Program (ISP), which will create opportunities for U.S. companies to compete with imported products and thus reshore. The ISP is designed to enable companies, industry associations, equipment suppliers and economic developers to cooperate to substitute domestic production for imports. Keep up with ISP updates by signing up for our eNewsletter or contact us directly to learn more.

Are you and your company using all of the Reshoring resources available on our website (www.ReshoreNow.org)? Here is a list of just a few helpful tools to aid in your reshoring decision-making process:

Help us reshore and restore U.S. manufacturing!

Harry Moser

President – Reshoring Initiative

Harry founded the Reshoring Initiative to bring manufacturing jobs back to the U.S. after working for high end machine tool supplier GF AgieCharmilles, starting as President in 1985 and retiring 12/31/10 as Chairman Emeritus. Largely due to the success of the Reshoring Initiative, Harry was inducted into the Industry Week Manufacturing Hall of Fame 2010 and was named Quality Magazine’s 2012 Quality Professional of the year. Harry participated actively in President Obama’s 1/11/12 Insourcing Forum at the White House, won The Economist debate on outsourcing and offshoring, and received the Manufacturing Leadership Council’s Industry Advocacy Award in 2014.

Harry is frequently quoted in the Wall Street Journal, Forbes, New Yorker and USA Today and seen on Fox Business, MarketWatch and other national TV and radio programs. He received a BS in Mechanical Engineering and an MS in Engineering at MIT in 1967 and an MBA from U. of Chicago in 1981.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.