Communication tools aiding manufacturers in a safe return to work as the COVID-19 pandemic rages on.

By Bill Homer, Senior Director, Solutions Architecture, Rave Mobile Safety

It’s no secret that the health and safety of manufacturing employees has always been top of mind in the industry. But the COVID-19 pandemic has added another layer of complication to safety concerns in manufacturing, and while previous safety efforts were largely focused on safety around machinery, the virus brought with it new concerns—like proper social distancing and ventilation.

To ensure employees stay both informed and safe as manufacturers ramp up operations in line with state guidelines or reconsider some of their existing precautions, workplace communication cannot be overlooked. By establishing best practices at their facilities, manufacturers can not only ensure employees have all the details they need to best protect themselves and their coworkers, but ultimately help reduce the spread of the virus.

While most organizations use email as the primary form of organization-wide communication, it’s important for manufacturers to evaluate the channels where employees are most likely to receive and read updates in a timely manner. Consider that most employees aren’t sitting at a computer with email open all day, or better yet, allow them to select the mode of communication via which they want to receive updates—for some, it may be email, but phone calls and SMS text messages should also be options.

While not every employee might read emails before coming to work, a phone call or text will ensure they receive critical updates that may impact their shift—like whether a coworker or visitor to the facility tested positive. Getting updates like this to employees in ways that guarantee they get the information is especially important given not all employees are in the facility at the same time to learn about an urgent update directly from a manager or through word of mouth.

Communication tools like mass notification systems, personal safety apps and mobile panic buttons are available to streamline the communication process—and they do more than just alert employees. Manufacturers can leverage tools like this to ensure employees have easy, quick access to emergency plans, emergency contact lists and other organization-specific information that will aid in response to any critical situation.

During the COVID-19 pandemic, manufacturing leaders must go beyond communicating with employees only when there’s an update. Daily health and wellness check-ins are imperative to determining if an employee isn’t feeling well, has experienced symptoms or come into contact with someone who has tested positive.

Daily health check-ins via text message that focus on a few simple but targeted questions like whether the employee has a cough or a fever ensure employers have an up-to-date understand of employees’ health status. This enables them to know in advance of a shift if an employee should stay home and if they need to begin alerting other employees of a potential positive case. Not only does this create an additional line of communication between employers and employees, it goes a long way to proactively protect the workforce.

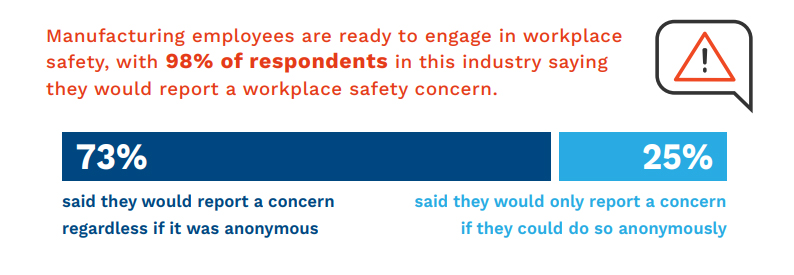

According to a 2020 Workplace Safety and Preparedness Survey conduct by Rave Mobile Safety, 98% of manufacturing employees reported that they are willing to engage in workplace safety.

While many of these communications best practices involve employers proactively reaching out to employees, it’s equally important for employees to have channels through which they can share information, raise concerns and have a clear line of communication to managers and leaders at their organization.

Anonymous tip lines are one way to ensure employees feel comfortable reporting their observations of noncompliance with social distancing and other facility safety guidelines in the age of COVID-19 so that they can be quickly addressed, employees feel heard and the entire facility community can stay safe.

Multiple touchpoints can help manufacturers ensure employees have the critical updates needed to keep facilities safe and employees protected no matter what emergency situation arises, ensuring facilities can operate efficiently while maintaining the health and safety of all who work there.

Bill Homer

Bill is the Senior Director of Solutions Architecture at Rave Mobile Safety. He has been with Rave for over 13 years and spent his first nine largely focused on Services and Support, where he managed and grew that team. He has personally been involved with hundreds of deployments of all solutions across all of the various verticals. Bill is now heavily engaged with the Sales team to provide technical and solutions expertise in the pre-sales process. Prior to his time at Rave, Bill enjoyed time with ESPN, AT&T and the U.S. Navy, where he was a Navy Logistics Officer.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.