Increased environmental regulations continue to drive the need for the efficient management of water used across semiconductor fabs.

By Prakash Govindan, COO of Gradiant

There is urgent need today for sustainability in water management at wafer fabrication and semiconductor manufacturing plants (or “fabs”). We are experiencing a global shortage of semiconductors that are required to control everything from automobiles to smartphones to appliances. As the semiconductor shortage persists, manufacturers are facing increasingly greater pressure to adopt sustainable and efficient practices in their water operations. Water serves a critical role in chip production, as it’s needed to rinse and clean silicon wafers as they are manufactured – and not just any water, but Ultrapure Water (UPW), which is thousands of times purer than drinking water. It takes roughly 1,400 -1,600 gallons of municipal water to make 1,000 gallons of UPW, with fabs using up to 5 million gallons daily.

At this time of unprecedented demand for semiconductors, severe droughts in major semiconductor manufacturing areas are threatening the operational continuity and expansion plans of brand owners and foundries. The intensive water consumption required by semiconductor fabs limits water availability for local households, businesses, and wildlife in the community. Further, in the major areas where fabs are located, such as Taiwan and the Western U.S., recent droughts have plagued these regions, thereby threatening the global supply chain, increasing the costs of production, and placing pressure on overall water availability.

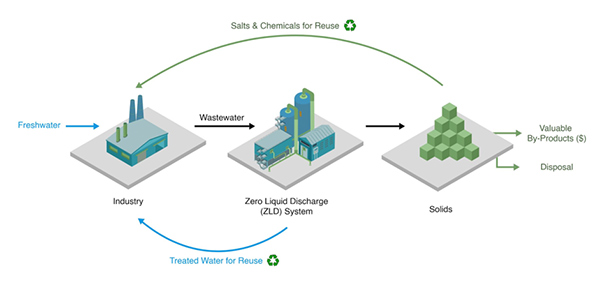

In response to prolonged droughts and increasing demand for semiconductors, brand owners and manufacturers are focusing on new ways to recycle, reduce, and reuse the water used in their production. New advancements in water treatment have emerged to allow semiconductor manufacturers to recover and reuse wastewater, remove targeted contaminants, and even reclaim valuable products from waste streams.

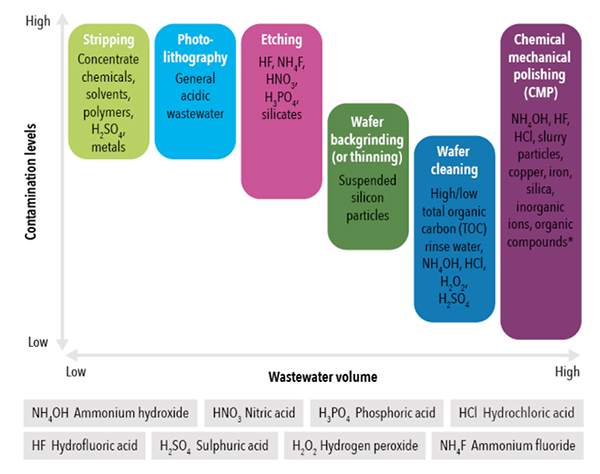

Water reuse with simple measures such as the cooling of equipment continues to be widely adopted due to the ease of implementation, but fabs are increasingly interested in treating and channeling individual streams of process wastewater, to serve as feedwater for UPW systems. This practice is complex as each wastewater stream is different, sometimes requiring its own treatment approach. When implemented in concert with other water management strategies, manufacturers can greatly reduce their overall water consumption and ensure sustainability and continuity in their manufacturing operations and supply chain.

Global leaders are becoming increasingly strict on water and wastewater quality and quantity as our freshwater resources are dwindling. Officials have recently announced ambitious goals to achieve a sustainable future, with a key focus to address the need for water. At the UN Climate Change Conference, better known as COP26, water was a primary focus of discussion. UN officials forecasted the world will see a 40% shortfall in water by 2030, prompting many leading brand owners from the world’s essential industries to pledge their operations will be net-water positive.

Outside of brand owners, many countries are also adopting initiatives for sustainable water management. In Asia, where most of the semiconductor manufacturing takes place, Singapore announced its Green Plan 2030 this year, to maximize the use of natural resources and reduce the amount of waste being discharged into the environment. As these initiatives and programs continue to grow and regulations related to water and wastewater management are enacted, brand owners and manufacturers are facing greater pressure to optimize their operations and minimize footprint through sustainable water practices.

The need for semiconductors will only grow in the future to address our insatiable appetite for technology and electronic devices in our daily lives. Innovation advancements in water treatment now allow industries to recover and reuse wastewater, remove contaminants, and reclaim valuable products from waste streams. As large chip fabs prepare for expansion in the coming years, advanced water and wastewater treatment will serve a critical role to meet the world’s demand for semiconductors.

About the Author

Prakash Govindan is the COO of Gradiant. Under his leadership, Gradiant has developed and commercialized a platform of sustainable clean water treatment technologies, with the goal of solving the most important water treatment challenges. Prakash leads Gradiant’s global project acquisition and execution work. Prior to Gradiant, he earned his Ph.D. in Mechanical Engineering at MIT and holds more than 100 patents. Prakash is based in Singapore.

About Gradiant

Gradiant is a global solutions provider and developer of cleantech water projects for advanced water and wastewater treatment, with focus on water reuse, industrial wastewater, resource recovery, and zero liquid discharge. Gradiant’s end-to-end solutions and technology expertise enable sustainable and cost-effective treatment of the world’s most important water challenges. With a full-suite of robust and proprietary technologies, powered by the top minds in water, Gradiant serves its clients’ mission-critical operations in the world’s essential industries. Today, with over 400 employees, Gradiant serves its clients around the world from its headquarters in Boston and Singapore and offices across ten countries. Gradiant creates new possibilities for water. For more information, please visit www.gradiant.com.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.