New study reveals how shippers/carriers approach KPI management – challenges they see and what they think industry benchmarks should be.

Freight shipping has never been more chaotic.

In this unpredictable freight shipping environment, businesses must make do with the resources they have, and their supply chain data can be one of the most valuable tools at their disposal.

Most businesses collect this data by setting and tracking key performance indicators, or KPIs. According to our latest research study, 83% of shippers agree KPIs are an essential part of sound supply chain management.

The ability to implement a data-driven shipping strategy can be the difference between a resilient supply chain and losing customers.

But knowing it is one thing — actually doing it is another.

To help businesses make better use of their shipping data, we asked hundreds of shippers and carriers how they manage, track and benchmark their performance metrics.

997 Shippers

683 Carriers

Though most every shipper agrees KPIs are important, that doesn’t mean every business finds them easy to manage.

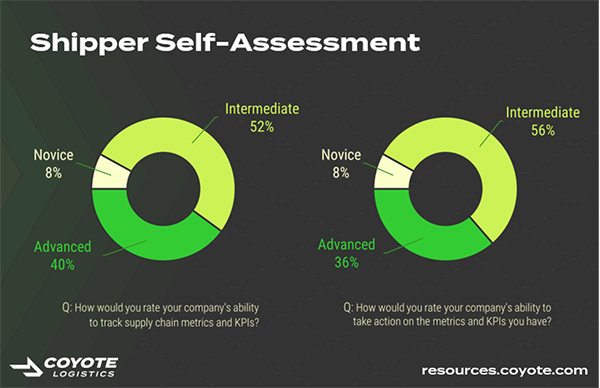

Our research found that though a vast majority of businesses have at least some level of competency with KPI tracking (only 8% of respondents thought they were KPI novices), fewer than half think they’re experts.

Most businesses believe they’re just OK, with a majority (52%) rating themselves as intermediate. Shippers are even less confident with their ability to take action on their data, with 55% rating themselves as intermediate — only 36% feel that they are true KPI experts.

By definition, every key performance indicator should matter, but not all KPIs are created equal.

When asked to choose, there was one clear winner: on-time delivery.

This was the only KPI that a majority (58%) of respondents noted as very important, a full 11% ahead of second place (cost per shipment at 47%).

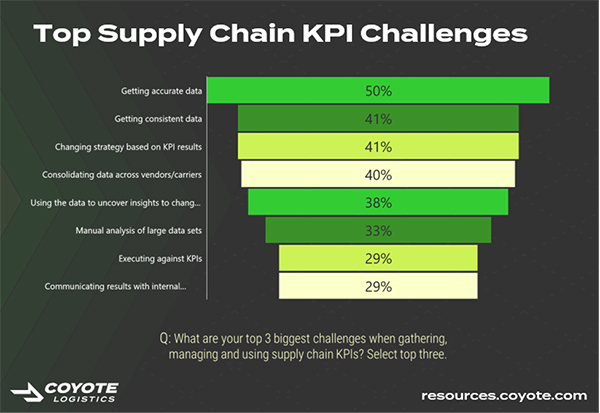

Over half of businesses think they are just OK at gathering and using supply chain KPIs — what specifically do they find so difficult?

Even though supply chains are more connected than ever, with smart phones, ELDs, RFID tracking and cloud computing, getting accurate data is surprisingly shippers’ top challenge.

In fact, it’s the only challenge that a majority of respondents ranked among their top three.

Getting consistent data (41%) and changing strategy based on results (41%) tied for second place among shippers’ top KPI challenges, followed closely by merging data across multiple providers (40%).

With three of the top four challenges related to data integrity and data management, it’s clear that logistics as an industry is still a ways away from true end-to-end visibility.

For all the advancements in technology, most businesses feel like they can be doing better. AI and machine learning may help bridge this gap in the future, we’re not there yet.

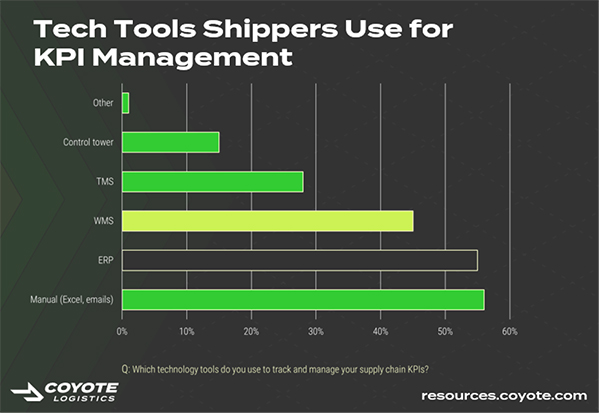

One reason gathering accurate data, gathering consistent data and merging data across providers are all listed as top KPI challenges may be that 56% of respondents are using free, manual, low-tech solutions to manage performance metrics.

Even with ERP, TMS and WMS technology available, most businesses still rely on the tried-and-true spreadsheet for at least some of their KPI management.

Even though 82% of shippers agree that technology will make KPI management much easier in the next two years, it’s clear most businesses today are still cobbling together solutions across multiple carriers, systems and business units.

The last two years have pushed supply chain professionals to their limits. Businesses in every industry are struggling to meet customer demands, whether from price inflation, scarcity of materials or lack of transportation capacity.

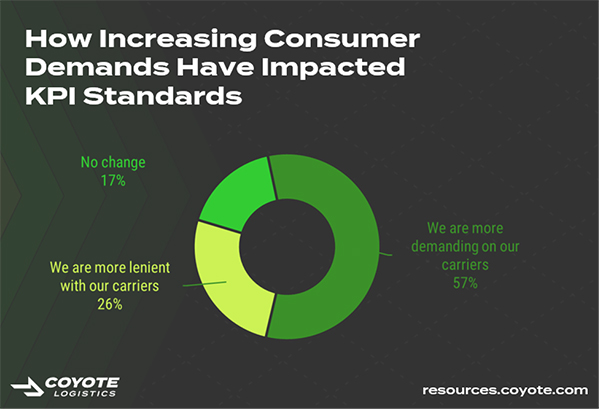

To try to keep up with their own customers’ demands, most shippers have raised their KPI standards for their carrier base.

Carrier management is an art and a science — you have to know when to push, and when to pull.

Your supply chain needs to meet service standards, but you also need to protect mutually beneficial, long-term relationships with your freight providers. Using KPIs, and communicating them in regular carrier scorecarding, can help.

Being data-driven extends beyond your high-level strategy — everyone in your supply chain should know your expectations, and your expectations should be constantly benchmarked against realistic industry conditions.

– Ben Steffes, VP, CTM & Managed Services, Coyote Logistics

Whether they’re ratcheting up the pressure, easing off or staying the same, businesses on both sides of the supply/demand divide want to reach a consensus.

As transportation increases in volatility, businesses are searching for a set of standards they can aim for to clarify for the entire logistics industry what is acceptable and what isn’t.

Working together is absolutely essential for better supply chain performance.

On average, shippers manage 42% of their KPIs using external resources, either relying on freight providers or outsourcing completely.

It can be very difficult to build logistics management capabilities internally, especially if you’re starting from scratch.

Knowing who to hire, where to invest and what processes to put in place can become a draining process of trial and error. Looking to your freight providers for guidance, or full outsourcing, can be a great way to close a talent gap quickly.

– Ben Steffes, VP, CTM & Managed Services, Coyote Logistics

Download the full research study to learn more about visibility expectations, where shippers and carriers think KPI standards should be set, whether asset-based carriers or brokers perform better, and more.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.