W&W/AFCO STEEL is a structural steel fabricator, fusing capabilities and longstanding industry-leading experience, producing a quality service and product that is unmatched in the industry.

With more than 1,000 dedicated employees, six state-of-the-art fabrication facilities, nearly 2 million square feet under roof, as well as client work that includes such world-renowned structures as the Dallas Cowboys Stadium, The New York Times Building, and the National 9/11 Museum Pavilion, W&W/AFCO STEEL stands tall among the world’s leading construction and steel fabrication organizations.

– Kronos Workforce Manager – used for labor forecasting and scheduling; reduces manual scheduling and helps to ensure optimal labor coverage for every shift

– Sage 300 Construction and Real Estate – construction and property management software – used for construction project management, estimating, accounting, document control and reporting, payroll, and procurement

– FabTrol – used for inventory tracking, backend production, inventory, purchasing, BOM, shipping, quality control, backend production management, and ERP

W&W/AFCO STEEL’s IT environment has grown steadily over the years, now supporting approximately 350 direct users. Commensurate with its steady growth from a small into a midsize IT organization, its IT budget has grown from small to midsize as well. However, maintaining its current budget while supporting the company’s unrelenting growth was becoming a challenge, felt most acutely across its rapidly growing Microsoft SQL Server environment.

All of W&W/AFCO STEEL’s primary applications run on Microsoft SQL Server. Originally, SQL Server was selected because W&W/AFCO STEEL’s IT management felt they could depend upon it with very little management intervention. However, as the environment continued to grow, the SQL Server environment began to experience performance issues. Initially, to address this problem additional SQL Server instances were added. However, this presented a new challenge – SQL Server sprawl. A SQL Server consolidation effort was initiated, bringing everything back into two servers. This appeared to be the perfect solution – until there was a failure.

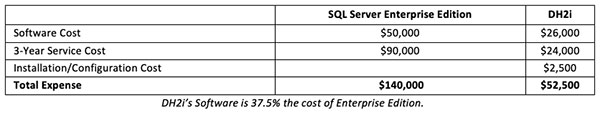

“We partnered with a professional services organization that specialized in SQL Server migration. Our goal was to migrate our SQL Server 2005 and 2008 to SQL Server 2012. The professional services organization continued to recommend Enterprise Edition (EE), however it was not really a fit for our mid-size IT budget. It is an incredibly expensive product and simply wasn’t a viable solution,” said Todd Park, Vice President Information Technology, W&W/AFCO STEEL. “Then, we had a failure, which affected a very large portion of our environment. We had to do something quick. As luck would have it, that’s when we discovered DH2i’s solution – an ideal fit for us from both a features and functionality standpoint, as well as a perfect fit for our budget.”

For Enterprise Edition, W&W/AFCO STEEL was quoted a three-year cost of over $50,000 for its two-server consolidated SQL Server environment. W&W/AFCO STEEL’s professional services consultant also presented a SQL Server Environment Management Proposal, which included SQL Server migration, monitoring, and management of the environment for one year that was over $30,000.

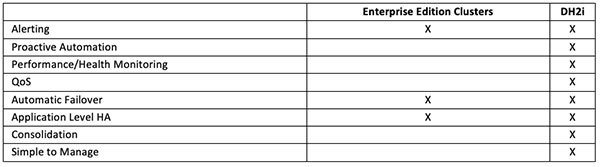

“With DH2i’s software, this expense is no longer necessary – it all goes away,” said Park. “DH2i provides all of it. Most importantly, it delivers the two things that matter most to us: failover and health monitoring.”

DH2i enables W&W/AFCO STEEL to organize its SQL Server instances into virtual hosts, which can be moved around the cluster as needed. If the node that is currently hosting a virtual host fails, the virtual host will automatically be restarted on another node with its associated instance. To choose the best node to host the virtual host, DH2i’s software will load the list of nodes that are eligible to host the virtual host, and eliminate nodes that are unavailable or lack access to the storage required to run the SQL Server instances. If more than one node fails, the DH2i software will start the virtual host on the highest priority eligible node, and raise an administrative alert that the node is over-allocated.

“During our extensive testing, the DH2i software worked exactly as it should. During the test failures, it failed-over perfectly. It is now in full production and working phenomenally,” said Park. “If it wasn’t, I’d know it.”

“When you have a small IT staff, you have to be able to wear many hats. We are not a small business anymore. We are growing as a company, the IT environment is growing, and with DH2i’s software, we can efficiently and cost effectively manage that growth,” said Park.

With DH2i, W&W/AFCO STEEL will now also set performance policies for each instance and server – utilizing metrics such as memory, CPU and I/O usage or network bandwidth. The DH2i software will then automatically monitor and move instances to meet their pre-set performance thresholds. W&W/AFCO STEEL will be able to set response policies ranging from a simple advisory message to a change-request requiring a response.

“This is one thing that helped cinch the deal for us,” said Park. “We needed to understand how much we are really utilizing per box, so we could know when it’s time to add another server.” He continued, “For our central applications, the server name was hard-coded in the client and there are about 60 clients. With DH2i, the server name is virtual – we can move the applications wherever, whenever.”

W&W/AFCO STEEL will be initiating another application migration shortly. It will leverage DH2i’s ability to dynamically move applications from one server host to another in less than 30 seconds. This speed will ensure that W&W/AFCO STEEL’s applications remain highly available at all times.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.