Technological advancements in excavation services has made the process simpler and easier for the workers. Read this article to learn more.

For a while now, technology has introduced radical changes in different industries. From telecommunications to smart homes to education and even mining practices. In the excavation industry, there have also been tremendous changes. Technology has eliminated the need for traditional excavation methods in heavy or light construction services. It has introduced modern machine learning capabilities, which have made experts smarter than ever before.

As a process of moving earth and other materials through bulldozers, backhoes, and earthmovers, technology in excavation has simplified the processes. The process was once very slow and time-consuming but is now easier regardless of the large amounts of dirt and materials. As a homeowner, you can also enjoy on demand excavation services with the assurance that technology tools which make the activity swift and neat will be utilized.

Many different types of machinery can be used for excavation work. Some examples are:

However, for large scale excavation services, more advanced technology are being adopted, and some of these are:

1. GPS Systems

Global Positioning System (GPS) is an innovation that has greatly improved excavation services. They allow people working on a job to see a visual landscape of the area they are working in and how the landscape will look after excavating. This helps them plan out what equipment they need and how much manpower they’ll demand to get the job done.

The GPS also gives the right excavator more accuracy when doing their work because it allows them to keep track of how deep they have gone, as well as where different layers are located throughout the site. This makes it possible for workers to know exactly where they are digging, so there would be no confusion about the area they’re supposed to be working.

Finally, having a GPS on-site eliminates the need for surveyors. These devices do most of their work automatically through software programs installed on the computers rather than the traditional pencil and paper.

2. Microprocessors

Another place of excavation technology services is the introduction of microprocessors. A microprocessor is a computer processor on a chip and can be used with a human driver or as a stand-alone component. This allows machines to be controlled using computers as opposed to a human driver, and it serves two purposes: It increases efficiency and decreases human error, making them safer to use.

Microprocessors can be used for different purposes within excavation machinery, from controlling operation speed and fuel consumption to displaying information about the vehicle’s condition on its monitor screen. You may also find that your excavator has an onboard computer that records data such as soil type, thicknesses measured by ground-penetrating radar (GPR), start/stop times, and machine status indicators so that you can keep track of this information later when analyzing performance over time or comparing machines against each other.

3. CAD Programs

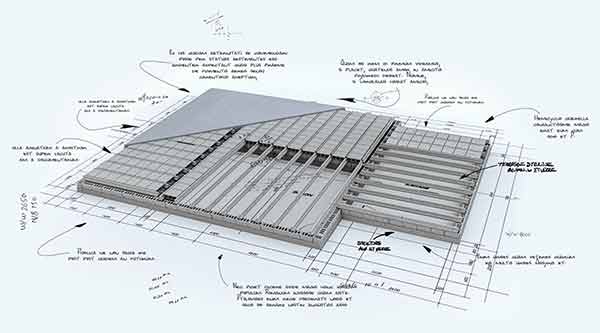

An interesting feature of technology in excavation services is Computer Aided Design (CAD) programs which can be used alongside GPS systems. They provide 2D and sometimes 3D site images for those inside an excavation site, so everyone sees the same thing when planning for a job. These images can even be used to create 3D models that simulate what would happen if a structure was built on top of an area with different elevation levels.

As excavation services are becoming more efficient with time, it is no longer time-consuming to dig up dirt, work on large construction sites, or complete a project efficiently. CAD programs make it easier, which means you don’t need to be on-site as a manager or a government official to oversee the work being done.

Excavation services is a sector that has witnessed great technological advancements in recent years. The newly emerged technologies have played a great role in changing how things were done previously and influencing how they will be done in the future. With technology in excavation, you can expect minimal disruption while digging through dirt or any other excavation-related work. This makes the process efficient, thorough, and fast.

David Hardin is a construction supervisor. He has been working in the construction industry for more than 10 years. He also shares his knowledge and expertise in the field through guest posts. In his free time, Davis enjoys hiking and boating.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.