Manufacturers should be aware of health-related information surrounding 3D printers and enact safety measures to protect users.

Dr. Marilyn Black, vice president and senior technical advisor for Underwriters Laboratories

A recent Forbes article states, “In 2020, 3D printing will confirm its role as one of the most transformational and consequential technologies in the fourth industrial revolution.”

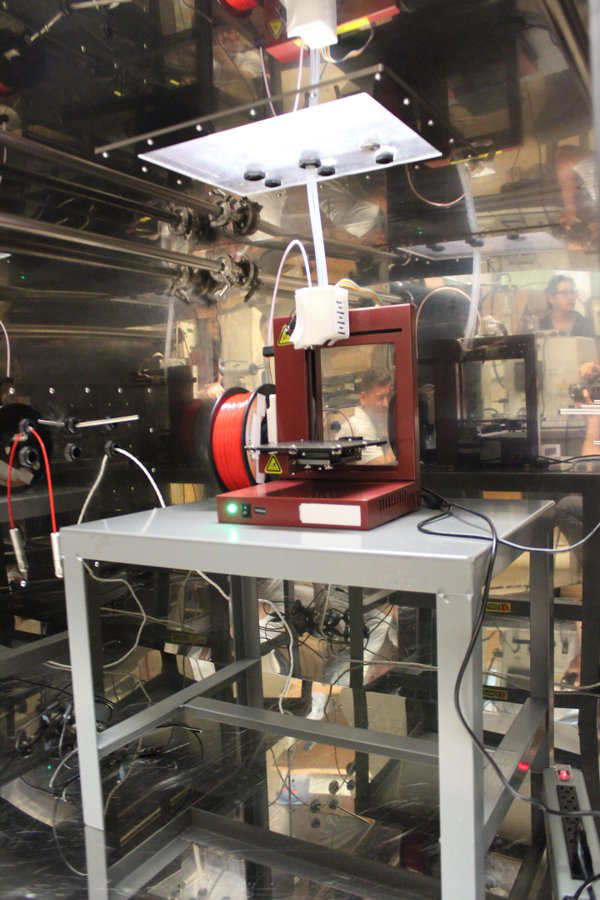

3D printing, an additive manufacturing technology, has rapidly progressed in many manufacturing sectors including aerospace, automotive, robotics, healthcare, and architectural design – to name just a few. As 3D printer functionality for prototyping and manufacturing finished products goes up and costs and difficulty of operation go down, consumption increases. While 3D printers’ ability to transform how objects are built and perform opens a wide array of possibilities, research shows it may also lead to unintentional safety concerns for users.

Manufacturers using 3D printers need to constantly update their knowledge regarding hazardous chemical and particle emissions resulting from printer use. They should also understand how facilities and workers can be protected from these hazards and other safety concerns. Doing so will not only help keep workers safe but will also help ensure that processes and procedures are put in place to manage and operate 3D printing facilities with safety in mind.

Potential practices include ways to exhaust or filter hazardous emissions. Users can also purchase or select printers and print media, also known as filaments, demonstrated to reduce these risks. Optimizing the use of print media that can accomplish performance and safety goals is important.

Chemical Insights and Georgia Tech conducted a research study to identify the emissions of 3D printers and evaluate potential hazards.

Hazards associated with 3D printing involve user exposure to chemical and particle emissions from heated filaments such as PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), nylon, PP (polypropylene), and other polymers and powders that may contain numerous additives such as flame retardants and metals.

Chemical Insights – an Institute of Underwriters Laboratories – and Georgia Institute of Technology have found that many desktop 3D printers, while in operation, generate ultrafine particles (UFPs) and numerous volatile organic compounds (VOCs) that may affect human health.

UFPs can be inhaled and penetrate deep into the human pulmonary system, triggering lung irritation, respiratory and chest discomfort, and asthma. Long-term exposure may lead to respiratory and cardiovascular diseases. VOC exposure can result in headaches, eye and nose irritation, and flu-like symptoms. These health concerns are especially noteworthy when 3D printers are used in small or poorly-ventilated rooms – such as small workshops or individual workstations, or large industrial spaces with multiple print units in operation and insufficient ventilation control.

While there are some occupational standards and guidelines for protecting workers in industrial environments mainly addressing specific VOCs and total particles, they do not address UFPs or many of the VOCs found in 3D printing emissions. There are no regulated standards for the general indoor air in homes, offices and school environments.

Since 3D printing is still a relatively new technology, information about health and safety implications is still being discovered. The Environmental Protection Agency (EPA) has increased its scrutiny of 3D printing emissions, all while predicting that the technology is just starting to revolutionize manufacturing and the supply chain.

Other than breathing in pollutants emitted from 3D printers, potential hazards, according to the National Institute for Occupational Safety and Health (NIOSH), include workers coming into contact with hot surfaces and moving parts; cleaning and changing printer heads and nozzles; loading filament into the printer; and collecting waste.

It’s important, therefore, for everyone involved with 3D printing to understand the potential dangers and to educate users on the risks and proper operational techniques. Employers should perform hazard assessments and ensure that printers are placed in locations with sufficient operating space and ventilation control.

NIOSH suggests the following to help keep 3D printer work areas and workers safe:

Additionally, Chemical Insights suggests:

Following its research, Chemical Insights worked with a range of stakeholders, including printer manufacturers and users, to create a national standard for testing and assessing particle and chemical emissions from 3D printers. The research focused on fused filament fabrication technology, but the methods presented in the standard are also applicable to other printer types.

The Standard, ANSI/CAN/UL 2904, contains measurement and health assessment protocols for emissions that can be released from print applications with 3D printers and print media. And while it applies to the printers typically found in schools, homes, offices, libraries, and other non-industrial indoor spaces, the impact on indoor air in manufacturing plants could be similar, too. The Standard can be accessed here.

3D printers are no longer a novelty – they’re ubiquitous across various industries. Increasingly, they are using a growing mix of print materials with complex chemistries – many of which have chemicals that have not been properly tested for health impacts.

The 2019 Wohler’s Report forecasts that spending on 3D printing products and services will reach $15.8 billion in 2020, $23.9 billion in 2022, and $35.6 billion by 2024. You name it – 3D printers will likely be able to do it – if they aren’t already.

And in the name of progress, manufacturers and all those embracing 3D printing must also understand the health and safety implications concerning workers and consumers alike. Although 3D printers have come of age, factors surrounding their safety, haven’t.

Dr. Marilyn Black

Dr. Marilyn Black is vice president and senior technical advisor for Underwriters Laboratories, leading its research institute Chemical Insights. She is the founder and former chairperson for both UL Air Quality Sciences and the GREENGUARD Environmental Institute. She is also the founder of the Khaos Foundation, a non-profit organization dedicated to protecting the health and well-being of children through education and research. Dr. Black is an active participant in national and international scientific organizational initiatives, research projects and community outreach programs, and has presented and published over 200 papers on indoor air quality and environmental exposure. She received a Ph.D. from the Georgia Institute of Technology, M.S. from the University of Florida and B.S. from the University of Virginia.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.