How the combination of business and ‘real world’ data will create resilient processes across the entire value chain.

By Dominik Metzger, Head of Product Management, Manufacturing & Industrial IoT at SAP

While we are no longer seeing the worst disruptions that the pandemic brought to global supply chains, manufacturing companies continue to face an onslaught of pressures, from rising trade tariffs between China and the US to unexpected setbacks, such as the recent blocking of the Suez Canal. At the same time, manufacturing industries have to juggle between customer expectations, such as highest quality standards and individualization of industrial products while staying highly profitable. In the next normal, modern enterprises have to embrace these challenges and transform the way to do business. They must create a business that is flexible enough to operate under any condition.

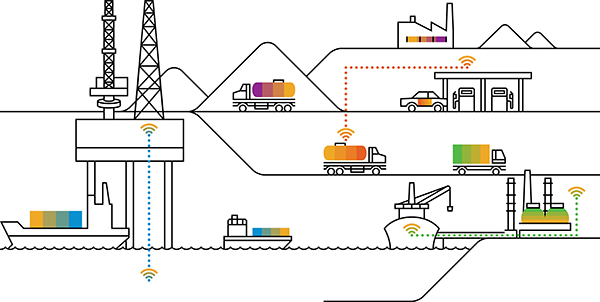

To do so requires more resilient and flexible supply chains, which are enabled by Industry 4.0, thanks to advances in the Industrial Internet of Things, robotics, artificial intelligence and cloud-/ edge computing. The level of complexity in supply chains of all manufacturing industries today is mindboggling, with each manufacturer typically having a web of global suppliers, sub-suppliers, production facilities and contract manufacturers around them. It is only through the combination of ‘real world data’ such as the temperature of a container and business data, such as the delivery and its contents, that true business process innovation is possible. Innovative technologies that combine data from the physical world with data from the world of business processes allows for massive amounts of data to be collected and used for process automation.

The key to building flexible and resilient supply chains lies in how well a manufacturer can harness industry data from processes occurring along the entire value chain. The data alone won’t create added value for businesses — it must be analyzed within a business context to efficiently reduce costs and increase productivity. It needs to become the foundation for artificial intelligence and process automation. Today, the most innovative manufacturers are already beginning to reap the benefits of data-driven supply chain technology by leveraging the power of the cloud combined with industrial IoT data and automation.

For example, by embracing these technologies, it is possible to fully automate the replenishment and retrieval process in intra-logistics processes of factories and plants. On the assembly line, it’s not unusual to use the Kanban process, in which material is made available at precisely the points on the assembly line where assembly or production workers need it. Sensors are installed in boxes that recognize when more of a material is needed by measuring the weight of the box. When the weight falls below a certain level, the procurement of supplies is automatically triggered, and more materials are brought in a worker on a forklift. This is an excellent step toward intelligent systems, but leading manufacturers that are designing the flexible supply chains of the future are already thinking ahead.

Through a cutting-edge integration of industrial IoT data, robotics and edge computing as well as a deep process integration of the manufacturing execution- and warehouse management systems, manufacturers will no longer require their forklift drivers to be in the right place at the right time to drop the materials off at the assembly line. Instead, Autonomous guided vehicles (AGVs), fully automated robots able to pick up on data cues, will be deeply integrated into the business’s enterprise software, and will fetch the required materials at the opportune moment. Along the entire logistics chain, smart sensors detect any damages to the materials and trigger according actions if needed. Thinks of a car battery which is highly receptive to damages through shocks which reduce its lifespan before being assembled in a vehicle. Meanwhile, the entire production operations will reap the benefits of highest automation and machine / device connectivity, embracing industry standards such as OPC UA to gather shopfloor data. Manufacturers that embrace these technologies will undoubtedly significantly reduce the amount of effort required for manual processes to reduce overall costs to the business.

Just as with cutting-edge robotics, new solutions were often expensive to implement in the past. But today, they are more affordable than ever due to a scalable cloud edge architecture and a high degree of standardization. In the past, implementing new solutions around Industry 4.0 had a much higher total cost of operations because infrastructure and hardware had to be deployed at each individual plant. Now, a large degree of manufacturing processes such as top-floor- and advanced analytics and insights can run seamlessly in the cloud. This means, for example, that only one data center is needed to manage processes such as Warehouse Robotics, Digital Manufacturing or Industrial IoT across dozens, or even hundreds, of plants.

These processes are ready for even the most mission-critical processes, which can run securely in each plant on a so-called edge device, a small server deployed on-site. Instead of re-implementing the processes plant by plant, they are configured centrally in the cloud on a plant-specific basis and operated as containers in the plant on the edge device. This is critical because, especially in robotics and automation processes, no business can afford to have the internet go down, even for a few seconds. Manufacturers that utilize an edge component for such high-availability scenarios will have the greatest confidence in their system’s robustness and their ability to operate without disruption. The extremely high amount of data which is gathered from shop-floor operations needs large bandwidth which is yet another advantage of an edge architecture before only relevant and selected data sets are given to the Cloud for advanced insights.

These innovations bring global manufacturers one step closer to the dynamic, automated processes that will keep businesses moving despite whatever difficulties or unforeseen changes may lie in wait in the coming years. From changing trade routes to natural disasters to more benign disruptions, modern manufacturers can continue to serve their customers with resilience by embracing innovative technology today.

About the Author

Dominik has a deep background in business process and solution consulting, especially in the area of the Digital Supply Chain. In his current role, Dominik works as the lead for the SAP industry 4.Now program. https://www.linkedin.com/in/dominik-mark-metzger/

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.