Crazing can be reduced in anodized aluminum by taking proper precautions and in consultation with experts.

Muskegon, MI – Lorin Industries, Inc., the global industry leader in the innovation and production of coil anodized aluminum, announces that anodized aluminum can be formed to minimize crazing – different from cracking – of the protective oxide layer. Lorin anodized aluminum can be used in a variety of applications when proper precautions are taken, in consultation with Lorin or forming experts.

All anodized aluminum, in fact all metals, can experience crazing if subjected to extreme temperatures, or if the metal sheets or rolls are formed at severe angles. “Crazing” is a term that describes micro fracturing of the anodic layer after anodized aluminum has been subjected to forming, fabrication, or extreme heat or cold. Crazing can sometimes be confused with “cracking” of the aluminum, but the two are not the same.

Anodize crazing does not break through the protective oxide layer and into the base aluminum. Cracking, on the other hand, is considered to have occurred when the oxide layer has been compromised to such an extent that the base aluminum is not only exposed, but also cracked and damaged itself. When this occurs, the oxide layer has been separated from the base aluminum and no longer acts as a protective layer along the crack. Unlike other coatings, with anodized aluminum the corrosion will not creep beyond the point where the cracking occurs. Cracking is less common, but more concerning, than crazing.

Crazing from forming stress, known as “mechanical” crazing, appears frosted or dull in appearance. Crazing from extreme temperature changes, known as “thermal” crazing, resembles a spider web. In either of these cases, crazing viewed through a microscope will show hairline surface cracks on the top of the oxide layer only, with no breakthrough to the base aluminum.

While mechanical crazing at the microscopic level can never be eliminated entirely (not even with pre-painted), visual mechanical crazing can be if the fabricated part or sheet is not subjected to any additional forming or extreme temperatures after anodizing.

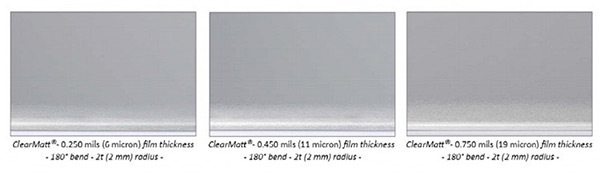

In a cost-effective, low labor coil anodizing process where parts are formed after the aluminum is anodized, mechanical crazing can be minimized by decreasing the radius of aluminum bends, decreasing the anodize film thickness, or using a colored anodize finish to make crazing less visible.

Given that thermal crazing occurs when temperatures exceed 320° F (160° C), the anodized aluminum experts at Lorin suggest that the anodized aluminum part or sheet not exceed 320°F and also does not come in contact with other materials at high temperatures that allow the anodized aluminum to reach 320°F in order to avoid and/or minimize thermal crazing. This is because aluminum undergoes more rapid thermal expansion than its anodic layer, causing thermal stresses large enough to cause crazing at any temperature above 320°F.

Although not roll forming experts per se, Lorin’s experience in working with successful customers can help offer guidance for customers to determine which potential solutions to reduce visible crazing are right for any given application; even though the protective anodic layer is unharmed by crazing, minimizing its visual impact can improve the visual quality of final parts.

About Lorin

Lorin Industries, Inc. has provided coil anodized aluminum to markets worldwide for over 60 years. Our history of global leadership in anodized aluminum finishing for architectural markets began with bringing the process to market in 1953, and continues today with industry leading innovation. Lorin has worked with some of the world’s foremost architects, designers, and fabricators to create new and exciting building designs that last throughout generations.

Whether used for exterior wall cladding systems, roofing systems, sunscreens, interior panels, or decorative interior applications, the possibilities for coil anodized aluminum are infinite. The natural beauty of Lorin’s anodized aluminum finishes brings newly constructed and renovated buildings to life, while providing a strong durable surface that will never chip, flake, or peel. Additionally, Lorin’s coil anodized aluminum products have been used for automotive, transportation, consumer appliances, and a number of other industries, with the same excellent aesthetics and durability long proven in architectural applications. At Lorin, we can help you reflect your vision with Lorin anodized aluminum.

For additional information visit www.lorin.com and follow Lorin on Twitter, Facebook, and LinkedIn.

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.