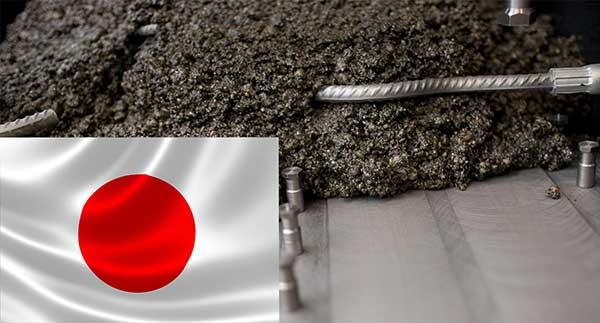

Business alliance agreement for the development, manufacture, and sale of EPUMENT® material for machine beds and components.

Osaka, Japan. HINODE, Ltd., and RAMPF Group Japan, K.K., have signed a busi- ness alliance agreement for the joint development, manufacture, and sale of EPUMENT® mineral casting products in Japan. The vibration-damping and environmentally-friendly material is used by renowned companies in the machine tool construction, semi-conductor, laser, medical, and packaging industries, amongst others.

HINODE, founded in 1919, is a leading developer and manufacturer of iron and polymer concrete castings for civil engineering applications. By combining this encompassing casting expertise and highly modern facilities with the unrivalled mineral casting know-how of the RAMPF Group, the partnership will establish Japan’s first-ever production facility for the innovative epoxy-bonded material.

Takeshi Asai, CEO of HINODE – “Mineral casting is predominantly man- ufactured in Europe, the United States, and China; until now, there have been no manufacturing sites in Japan. With this partnership, we will in- crease the availability of mineral casting on the Japanese market, signif- icantly decrease delivery times, and speed up the development and pro- duction of cutting-edge machinery. Together with RAMPF, the world’s largest manufacturer and a pioneer of mineral casting technology, we are providing machine builders in Japan with a truly unique offer for the production of machine beds and components.”

Yoshi Naganuma, CEO of RAMPF Group Japan – “We have been provid- ing customers in Japan with an holistic service offering for the develop- ment and manufacture of customized multi-axis moving systems and basic machinery based on EPUMENT® mineral casting since 2005. With HINODE as our partner, we can now utilize the material’s enormous tech- nical, economical, and ecological benefits even more effectively. We look forward to working together with the proven experts of HINODE and tak- ing mineral casting in Japan to an entirely new level.”

In addition to manufacturing mineral casting products at the HINODE factory in Tochigi, the business agreement encompasses a research and development collaboration with the mineral casting expert Pro- fessor Naohiko Sugita from the School of Engineering at the University of Tokyo. The objective is to further advance the quality and manufacturing process of mineral casting for the Japanese market.

EPUMENT® mineral casting is a high-performance machine bed and construction material consisting of selected mineral fillers and a high-quality epoxy resin-based binding agent. The main benefits are:

The international RAMPF Group is present in Japan with a subsidiary in Osaka and sales offices Kantō and Chūkyō regions. The product portfolio encompasses:

The international RAMPF Group stands for engineering and chemical solutions and caters to the economic and ecological needs of industry. The Group secures its presence on the international markets with 900 employees and six core competencies:

RAMPF has subsidiaries in Germany, the U.S., Canada, China, Japan, and Korea.

All RAMPF companies are united under a holding company – RAMPF Holding GmbH & Co. KG – based in Grafenberg, Germany.

Published by:

RAMPF Group Japan, K.K.

Oriental Shin-Osaka Building 2F

No. 8 North Lou Jiang Road

Nishinakajima 7-1-26 I Yodogawa-ku

532-0011 Osaka

T +81 66101 0769

E info@rampf-group.com.jp

www.rampf-group.com.cn

Scott Ellyson, CEO of East West Manufacturing, brings decades of global manufacturing and supply chain leadership to the conversation. In this episode, he shares practical insights on scaling operations, navigating complexity, and building resilient manufacturing networks in an increasingly connected world.